Facing the task of filtering in the lab and not sure which fritted Buchner funnel to use? Opt for clarity over guesswork. Here, we dissect the key factors—material, porosity, and size—that define your funnel’s performance. No fluff, just the essentials you need for a smart, lab-savvy choice.

Key Takeaways

- Fritted Buchner funnels provide efficient filtration due to their unique design which includes a fritted disc for even filtration, an airtight seal for effective vacuum suction, and optimal pore size options to cater to different filtration needs.

- Material selection is crucial for the durability of fritted Buchner funnels, with glass being common for chemical compatibility, and plastic offering affordability and resistance to breakage despite potential for discoloration and chemical absorption.

- Regular maintenance and proper cleaning are essential for the longevity of fritted Buchner funnels, and users should be aware of signs of wear, such as frit damage or discoloration, to prevent contamination and inefficiency in the filtration process.

Understanding Fritted Buchner Funnels

Whether you’re a seasoned lab professional or a student beginning your lab journey, you’ve likely encountered a Buchner funnel. These devices, specifically the fritted variety, are a staple in many commercial laboratories due to their efficient filtration abilities, outperforming traditional filter paper.

But what sets fritted Buchner funnels apart? It’s all in their design and filtration mechanism. This makes them a versatile tool capable of handling a variety of filtration needs.

But before we dive into the code:specifics, let’s take a closer look at the components that make these funnels work so effectively.

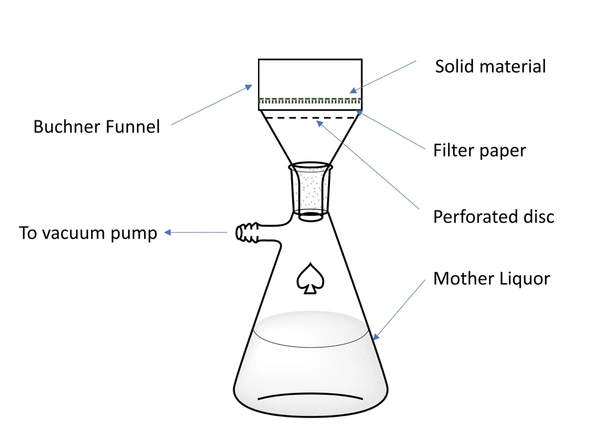

Components of a Fritted Buchner Funnel

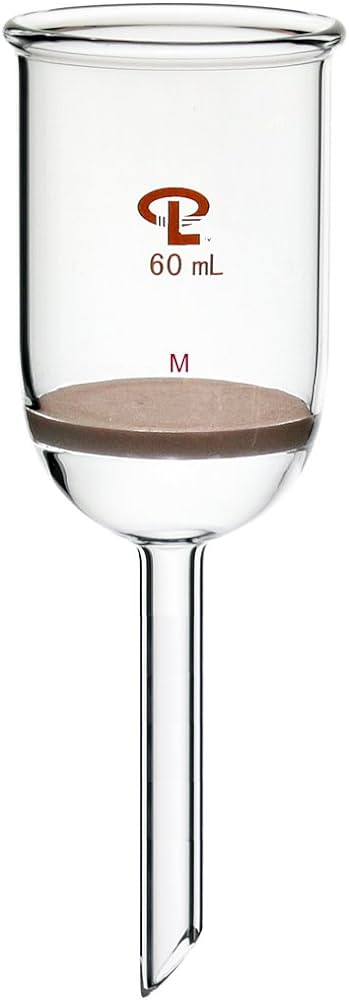

At the heart of every fritted Buchner funnel is, of course, the fritted disc. This disc, laden with minuscule holes, enables even filtration, ensuring no particle is left behind. The disc is encased in a solid, cylindrical body designed to withstand and to prevent over-filling during the filtration process, a common issue with other types of funnels.

But that’s not all. The bottom of the funnel fits snugly through a rubber stopper, creating an airtight seal necessary for effective filtration. This seal, combined with the hose barb connection on the attack of the filtrate funnel, allows for the application of a vacuum, facilitating efficient siphoning of material through the fritted disc.

Now let’s explore how this all works together.

Filtration Mechanism

The magic of a fritted Buchner funnel lies in its filtration mechanism. Unlike gravity filtration, these funnels use a vacuum pump to pull liquids through qualitative filter paper and the fritted disc’s perforations at the top of the funnel. This method significantly accelerates the filtration process, saving valuable time in the lab.

For optimal use, it’s crucial to:

- Insert the Buchner funnel through a rubber cork, creating an airtight seal

- Position the filter paper correctly over the holes to prevent clogging

- Ensure the fritted glass disc or perforated plate serves as the filtration surface, drawing the liquid through with vacuum suction

But there’s more to this case to consider when choosing a Buchner funnel, let’s examine the importance of material selection.

Material Selection for Fritted Buchner Funnels

While understanding the working of a fritted Buchner funnel is crucial, selecting the right material is equally vital. The funnel’s durability depends on its resistance to chemical attacks from cleaning and usage processes. Therefore, it is important to consider the material compatibility and proper maintenance in order to prevent the frit from becoming brittle or dissolving.

If the frit shows signs of erosion due to incompatible chemical exposure or improper practices, it’s an indication that the funnel is no longer suitable and should be replaced. But how do you choose between glass and plastic funnels? Let’s break down the advantages and disadvantages of each.

Glass Funnels

Glass fritted Buchner funnels are a common choice in many laboratories. But like all materials, they come with their own set of advantages and disadvantages.

<< Knowledge base for “Section 2.1 Glass Funnels”: To be continued >>

Plastic Funnels

Plastic fritted Buchner funnels, while often more affordable than their glass or porcelain counterparts, may have their own set of challenges. They may face chemical attack issues with certain solvents and harsh chemicals, which could affect the filtration process in a limited way.

On the bright side, plastic funnels are relatively more durable than glass, making them less prone to breakage. However, over time, they can become discolored or absorb some chemicals, which could potentially contaminate future filtrations.

Now that we’ve discussed material selection, let’s move on to another critical factor in choosing a Buchner funnel: the porosity of the fritted disc.

Fritted Disc Porosity Options

The fritted disc, the heart of the Buchner funnel, serves as the primary unit of filtration media in the separation of mixtures. Its porosity, or the size of its tiny holes, is a key factor in determining the overall speed of filtration necessary for laboratory procedures.

The porosity of the fritted disc can range from fine to coarse, each offering different flow rates of air and water, depending on the needs of the experiment. With listed porosity options available, let’s explore the nuances of these choices and their implications for your lab work.

Fine Porosity

Fine porosity fritted discs, with pore sizes typically around 4 mm-5.5 microns, are the go-to choice when you need to filter very small particles. These discs ensure precise particle retention, making them ideal for analytical work that requires the filtration of bacteria and fine precipitates.

While fine porosity discs offer high precision, they might not be the best choice for all filtration tasks. That’s where medium porosity fritted discs come in.

Medium Porosity

Medium porosity fritted discs:

- Have pore sizes between 10-15 microns

- Strike a balance between filtration speed and efficiency

- Retain fine particles during filtration without slowing down the process excessively.

Given their balance of properties, medium porosity fritted discs are versatile, making them suitable for a variety of filtration tasks that do not require extremely fine or coarse filtration. But what if you need to filter larger particles or achieve high flow rates? Enter coarse porosity fritted discs.

Coarse Porosity

Coarse porosity fritted discs, defined by their pore sizes ranging from 40-60 microns, excel at filtering larger particles. They can handle substances with a wide range of particle sizes without easily clogging, making them a preferred choice in situations where high flow rates and fast filtration are beneficial.

Now that we’ve covered the various porosity options, let’s turn our attention to another key consideration when choosing a Buchner funnel: size, capacity, quantity, and availability.

Sizing and Capacity Considerations

Fritted büchner funnels come in a range of sizes, typically categorized based on their volume capacity and the dimensions of the joint and hose barb. The right size and capacity ensure efficient filtration without risking overflow or contamination.

But how do you determine the appropriate size and capacity? Let’s delve into the specifics, looking at funnel diameter, stem length, pressure and volume capacity.

Funnel Diameter and Stem Length

The diameter of a Buchner funnel directly impacts the speed of filtration. Larger diameters provide a greater surface area for filtration, resulting in quicker filtration times. The stem length, on the other hand, is crucial for ensuring stability during the filtration process. The right stem length ensures that the funnel fits properly with the receiving vessel, maintaining stability during the filtration process. However, size isn’t everything. Let’s consider volume capacity next.

Volume Capacity

The volume capacity of a fritted Buchner funnel is key to avoiding overflow during the filtration process. An overflow can lead to contamination of vacuum equipment, impacting laboratory safety and experimental results.

Choosing a quality funnel with the appropriate volume capacity ensures a smooth filtration process, keeping your lab safe and your results reliable. But which brands and products should you consider? Let’s find out.

Top Fritted Buchner Funnel Brands and Products

With so many fritted Buchner funnel brands and products available in the market place, it can be challenging to make a choice, especially when considering the list price and available stock.

Maintenance and Replacement Tips

Once you’ve chosen your Buchner funnel, maintaining it properly can ensure its efficient service for many years in your lab. Proper cleaning involves:

- Removing all residues

- Gently scrubbing the frit without causing damage

- Utilizing appropriate solvents

- Allowing the funnel to soak overnight in a compatible cleaning solution.

But proper maintenance isn’t just about cleaning. It’s also about product storage, and knowing when it’s time to replace your funnel.

Cleaning and Storage

Cleaning your fritted Buchner funnel immediately after use can simplify the cleaning process substantially. Avoid using hard tools like spatulas to scrape the fritted disc, as this might cause damage and lead to contamination.

Applying vacuum filtration techniques during cleanup ensures thorough cleaning of fritted Buchner funnels, keeping them ready for the next filtration task. But how do you know when it’s time to retire your funnel? Let’s explore some signs of wear and replacement.

Signs of Wear and Replacement

A damaged or cracked frit is a clear sign that the funnel needs to be replaced to prevent contamination of the filtrate. Discoloration of the frit that cannot be removed with cleaning may suggest degradation of membranes in the material, which could compromise filtration efficiency and purity.

Signs of permanent staining can lead to reduced filtration efficiency, indicating the need for replacement. If the fritted glass becomes excessively clogged and cannot be cleared with regular cleaning methods, it’s time to consider a replacement.

Now that we’ve covered all the essentials and gained additional strength in our knowledge, let’s summarize our findings in our own review and discuss the benefits of extra strength in this review. Don’t forget to check out other reviews for more information and insights.

Summary

Choosing and maintaining a fritted Buchner funnel involves considering several factors, from material selection and fritted disc porosity to appropriate sizing and capacity. With the right funnel and proper maintenance, you can achieve efficient and reliable filtration results, ensuring the success of your lab work.

Certified MTP has an elite selection of lab solutions, showcasing industry-leading brands including Flasks, Beakers, Pipettes, & Graduated Cylinders, Buchner Funnels, Erlenmeyer Flasks, Measuring Pipettes, Stainless Steel Beakers, Glass Graduated Cylinders, and Plastic Graduated Cylinders.

Frequently Asked Questions

What is a fritted funnel?

A fritted funnel is a piece of lab equipment used for vacuum filtration, featuring a porous glass disk in the middle that allows liquid to pass through while retaining solids. While they are more convenient than Buchner funnels due to the absence of filter paper, they can be challenging to clean.

What is the difference between a Hirsch funnel a Büchner funnel and a fritted funnel when is one used over another?

The Hirsch funnel is smaller with outward-angled walls, while the Büchner funnel has a larger plate and vertical walls. A fritted funnel can be constructed and used immediately for filtration.

What is a sintered funnel used for?

A sintered funnel is used for filtering solid matter out of a solution, with a flat disk of glass containing millions of microscopic holes to trap solid matter while allowing liquid to pass through.

How does a fritted Buchner funnel work?

A fritted Buchner funnel works by using a vacuum pump to draw liquids through a fritted disc and filter paper, allowing for faster filtration than gravity filtration.

How do I choose the right material for a Buchner funnel?

Consider the resistance to chemical attacks, solvent compatibility, and budget when choosing a Buchner funnel material. Glass is resistant but breakable, while plastic is durable but may have chemical compatibility issues. Choose based on your specific needs and constraints.

Related Blogs for Fritted Buchner Funnels