Need to ensure your concrete slab is ready for flooring? Accurate moisture measurement is key, and our guide to the best moisture test kit for concrete will show you how. Expect to learn how to choose, use, and interpret kits, solidifying the foundation for your installation project.

Key Takeaways

- The Calcium Chloride Test, according to ASTM F1869, is trusted for measuring moisture vapor emission rate in concrete floors, requiring precise setup, environment control, and result interpretation.

- Reliable pH test kits are essential for determining the alkalinity of concrete floors to prevent flooring failures, with the accuracy dependent on consistent environmental conditions and correct testing procedures.

- Comprehensive moisture test kits, adhering to standards like ASTM F1869 and F2170, are crucial for aligning with flooring manufacturers’ specifications, with test kit selection and correct equipment usage being vital for accurate results.

Understanding the Calcium Chloride Test

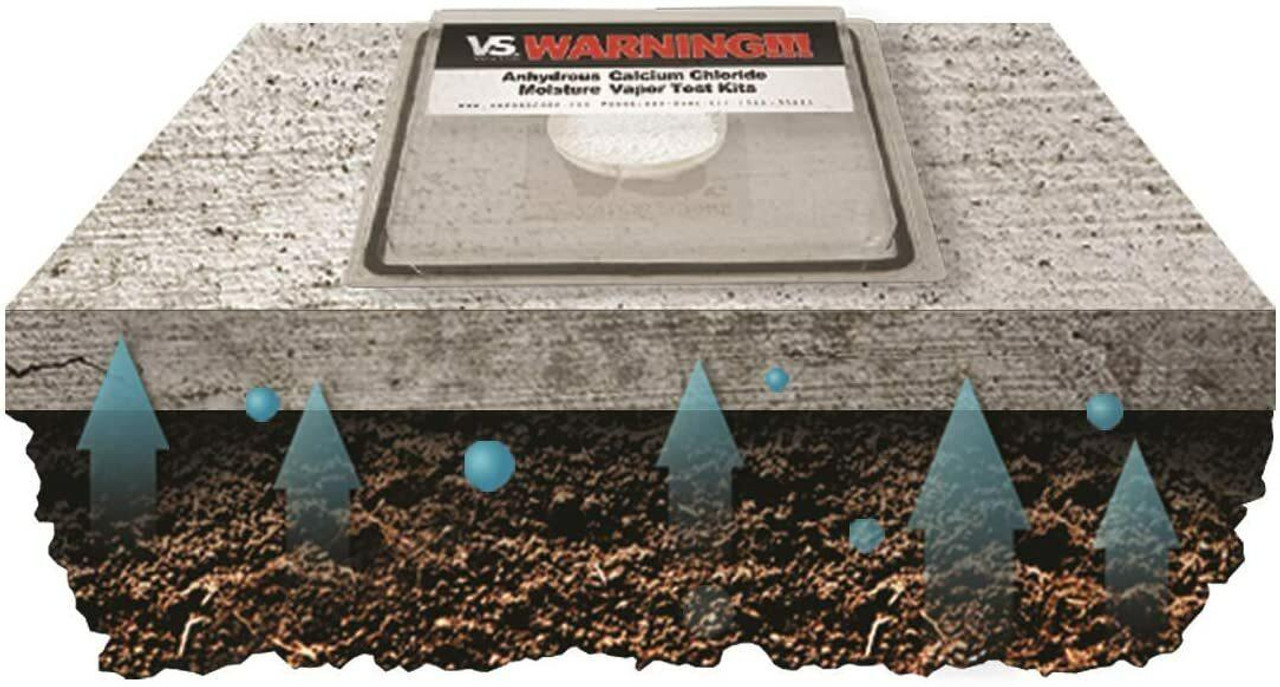

The Calcium Chloride Test, adhering to the ASTM F1869 standard, is a widely adopted method for determining the moisture vapor emission rate (MVER) in concrete floors. The test employs anhydrous calcium chloride to quantify the MVER of concrete subfloors, providing a reliable measure of moisture levels at the time of testing.

While the test results accurately depict moisture conditions at the time of testing, keep in mind that they may not necessarily predict future conditions that could impact the flooring material.

The Role of Anhydrous Calcium Chloride

Anhydrous calcium chloride plays a significant role in the moisture vapor emission test. This compound absorbs moisture from both the air and the concrete slab when contained in a sealed dish beneath a plastic dome. The change in weight of the anhydrous calcium chloride after a typical three-day period is used to calculate the MVER, providing a quantifiable measure of the concrete slab’s internal moisture.

This process, outlined by the ASTM F1869 standard, ensures the accuracy and reliability of the test results by following the widely accepted quantitative method and instructions recommended test methods.

Setting Up the Test

Correct test setup is vital to ensure the accuracy of results. The first step involves cleaning the testing area and removing any foreign substances such as adhesives and sealers. This is typically achieved by grinding the surface until the concrete is bare.

Maintaining specific environmental conditions – between 65°F and 75°F with 40% to 60% humidity – for 48 hours before and during testing is necessary.

Interpreting Results

Interpreting the results of the Calcium Chloride Test involves a calculation of the MVER. The weight gained by the calcium chloride after exposure to the concrete slab is used in a formula that accounts for test duration and area. This provides a measure of moisture emission in pounds over a 1000 square foot area for a 24-hour period.

The calculated MVER is then compared against the specified moisture tolerance levels provided by flooring manufacturers to determine if the concrete slab is appropriately dry for the installation of floor coverings.

Selecting a Reliable pH Test Kit for Concrete

Just like moisture testing, pH testing plays a crucial role in concrete flooring. The pH level significantly impacts durability and structural integrity. When using a reliable pH test kit, it’s essential to create an aqueous solution from the powdered concrete material for accurate measurement, given that concrete is solid and pH pertains to aqueous solutions.

Accurate pH readings can prevent adhesive residue issues and installation failures in concrete floorings, ensuring a long-lasting and visually appealing concrete floor.

Importance of pH Level Consistency

Maintaining consistent pH levels is key for precise pH testing of concrete. The site should be conditioned to the same temperature and humidity expected during normal use prior to pH testing. Specifically, the pre-testing environment should consist of 75 ± 10°F temperature and 50 ± 10% relative humidity.

These conditions must be maintained for at least 48 hours prior to and during the actual pH testing to achieve consistent and accurate results.

Using pH Test Kits Effectively

Effective use of pH test kits is vital for achieving precise results. Taylor Tools provides a specific procedure for conducting pH tests on concrete floors. This procedure involves cleaning the concrete floor, applying pH Balanced Testing Fluid, and then measuring the surface alkali content using a narrow-range pH strip.

Remember that an acceptable pH level for concrete flooring should be 9 or lower. This is endorsed by both the Carpet and Rug Institute and the Canadian Carpet Institute, emphasizing the significance of accurate pH testing during adhesive and sealant replacement.

Comprehensive Moisture Test Kits

Comprehensive moisture test kits are key in providing measurements that align with the moisture content specifications of flooring manufacturers. These test kits measure the weight in pounds of water vapor from evaporation over a 1,000 square foot area in a 24-hour period, adhering to the ASTM F1869 standard.

Furthermore, ASTM International’s F2170 standard for in situ relative humidity (RH) testing is recognized for delivering scientifically reliable moisture condition results within concrete slabs.

Choosing the Right Moisture Test Kit for Concrete

Selecting the appropriate test kit is vital since not all moisture test kit for concrete are compatible with every type of concrete floor. Lightweight concrete and gypsum floors, for instance, require different moisture testing procedures than more traditional concrete floor slabs.

ASTM standards F2471 and F710 provide guidance on alternative testing procedures and preparing concrete floors for resilient floor installations, ensuring accurate results for different types of concrete floors.

Equipment Required for Testing

Beyond the moisture test kits themselves, certain moisture test kit for concrete is required to conduct the tests accurately. This might include:

- Tools for cleaning the concrete surface

- Equipment for maintaining the required environmental conditions

- Tools for setting up the test kit

- Instruments for measuring the weight change in the anhydrous calcium chloride.

Using the correct equipment, moisture test kit for concrete, and following the recommended test methods is crucial for obtaining reliable moisture and pH readings, thereby ensuring the long-term performance and integrity of the concrete flooring.

The Significance of Accurate Moisture Testing

Precise concrete moisture testing is critical in preventing flooring issues resulting from excessive moisture in concrete. Advanced moisture testing methods, such as in situ relative humidity tests, reveal moisture content throughout the entire concrete slab, not just at the surface.

Adhering to the ASTM F1869 standard, which provides a quantitative measure for MVER, helps to determine the suitability of concrete floors for resilient floor coverings.

Preventing Future Flooring Problems

Ensuring the concrete slab is sufficiently dry before installing flooring materials prevents a host of issues, including:

- Adhesive failure

- Wood warping or cupping

- Gaps

- Creaking

- Blistering

- Delamination

- Growth of mold and mildew

Protective coatings like epoxy or polyurethane can be applied to create a moisture barrier, enhancing the concrete floor’s durability against chemicals and physical wear.

Free Taylor Tools Analysis

Taylor Tools offers users the option for the company to perform calcium chloride moisture test and analysis, ensuring reliable results. Moreover, to utilize this free analysis service, users must properly record the start and end dates and times on the calcium chloride test kit label, ensuring no spilling of calcium chloride occurs. Trust the accuracy and reliability of your results with our Taylor moisture and calcium chloride test kits.

Consulting ASTM F-710 and F-2471 standards during the testing process is also necessary for appropriately preparing concrete floors for analysis by Taylor Tools, using the preferred taylor test methods.

Shipping and Handling of Test Kits

Once ordered, we typically ship moisture test kits within 24 hours, ensuring rapid dispatch. We usually complete delivery for moisture test kits within 2 to 5 workdays across the lower 48 states. A quick turnaround time enables prompt moisture testing, facilitating timely decisions for flooring installations without delays.

Expedited Delivery Options

Contact the supplier in advance for expedited shipping or shipments beyond the lower 48 states and Canada. This enables the supplier to arrange fast delivery of the test kits to you.

Safe Packaging Practices

Proper packaging of moisture test kit for concrete is key to maintaining their reliability and integrity during shipment. High barrier materials package kits to shield them from moisture and oxygen, ensuring their reliability. To ensure accuracy, ph test strips sealed in their packaging are essential for optimal performance.

Manufacturers often include desiccants in the packaging to maintain a low relative humidity, safeguarding sensitive components from humidity damage.

Maximizing the Lifespan of Your Concrete Flooring

Several strategies can be implemented to extend the lifespan of concrete flooring, including:

- Prompt repair of minor damage such as cracks or chips

- Customizing maintenance procedures to meet the specific demands of various industries

- Implementing advanced monitoring technologies like sensors and AI to enable early detection of damage and facilitate timely maintenance

By following these strategies, you can significantly increase the lifespan of your concrete flooring.

Sealing Solutions

Sealing solutions can further enhance the performance and longevity of concrete flooring. Waterproof industrial concrete floors and coatings prevent water damage and ease cleaning in fast food restaurants and manufacturing plants.

Antimicrobial surfaces prevent harmful microbes and are ideal for food, beverage, medical, and pharmaceutical industries.

Industry Standard Best Practices

Adherence to industry-standard best practices is crucial for prolonging the lifespan of your concrete flooring. Additionally, regularly inspecting and maintaining concrete floors prevents potential issues from becoming significant problems. Furthermore, employing high-quality concrete mixes and adhering to recommended curing times and processes prevent premature deterioration of concrete floors.

Summary

In conclusion, accurate moisture and pH testing of concrete floors is crucial for ensuring longevity and performance. Choose the right moisture test kit, follow industry best practices, and use Taylor Tools’ free analysis to prevent flooring issues. Remember, investing time and resources in accurate testing today can save you from costly repairs and replacements down the line.

Certified MTP has the largest selection of concrete testing supplies and meters for concrete moisture testing, showcasing industry-leading brands for Slump Cones, Tamping Rods, Concrete Air Entrainment Meters, slump testers, Concrete Test Cylinder Molds, and fresh concrete testing equipment. We also offer the largest selection of tamping rods for concrete tests.

Frequently Asked Questions

What is the best moisture test kit for concrete?

The best moisture test kit for concrete is the in situ method using a hygrometer, which has been the industry standard for over 30 years. It led to the creation of ASTM F-2170 for measuring concrete moisture levels.

What is acceptable moisture level in concrete?

The acceptable moisture level in concrete, according to ASTM standard, is at or below 75% when tested using ASTM F2170, unless alternate guidelines are provided by the flooring system manufacturer.

How much does concrete moisture testing cost?

The cost of moisture testing by IFTI can start at around $1,000, and it reflects the value of professional moisture testing in preventing floor failures. Consider this investment for reliability and prevention of moisture-related issues.

What is the Calcium Chloride Test?

The Calcium Chloride Test is a standardized method for measuring the moisture vapor emission rate (MVER) in concrete floors, allowing for accurate assessment of moisture levels, making it the ideal moisture test kit for concrete.

Why is pH testing of concrete floors important?

pH testing of concrete floors is important to ensure the durability and structural integrity of the flooring material.

Related Blogs for Moisture Test Kit for Concrete:

Top Moisture Testers: Perfect Match for Your Farming Needs

Moisture Test: Tactics for Concrete Floor Assessment

Equipment Used to Determine Moisture Content in Materials

Moisture Testing: Tips for Accurate Concrete Analysis

How to Deal with Moisture in Concrete Floors

How to Use a Concrete Moisture Testing Kit

Moisture Testing: What Are the Different Types