Concrete Mixer Drill : Master the Mix for Your Project

Selecting the best concrete mixer drill for your project doesn’t have to be complex. With the key considerations of power, versatility, and consistency in mind, this guide will navigate you through identifying a concrete mixer drill that maximizes efficiency on job sites or at home. Explore the benefits, get tips on selection, and discover some of the top choices in the market, equipping you to make an informed decision.

Key Takeaways

-

Concrete mixer drills are essential tools in the construction industry, offering time savings, consistent mixing results, and versatility with different materials, which positively impact productivity and quality of construction projects.

-

Selecting the correct concrete mixer drill involves considering factors such as power and torque requirements, chuck size compatibility, and speed control features to ensure efficiency and compatibility with various paddle mixer attachments.

-

Proper use of a concrete mixer drill includes using the appropriate paddle mixer attachments for the material’s viscosity, ensuring maintenance and care of the equipment, and adhering to safety measures to guarantee both operator safety and mixture quality.

The Benefits of Using a Mixer Drill

Mixer drills have become an essential tool in the construction industry and for good reason. They offer numerous benefits, making any concrete or mortar mixing job a breeze. The use of a concrete mixer drill not only saves time and effort but also ensures consistent mixing results, which is crucial for any construction project. These benefits make concrete mixer drills a valuable asset for both professional builders and DIY enthusiasts.

The ergonomic design of these drills reduces the risk of musculoskeletal disorders that can arise from repetitive manual mixing. Furthermore, concrete mixer drills are incredibly versatile, able to speed up progress in various projects, from setting foundations to building sheds. We will examine these benefits in greater detail.

Time and Effort Savings

The foremost advantage of using a mixer drill is the substantial time and effort savings. Manual mixing can be tedious and time-consuming, especially when dealing with larger volumes. However, with a concrete mixer drill, you can mix materials quickly and efficiently, making it perfect for more extensive projects like fence posts or using mortar or multiple bags of Quickrete.

Concrete mixer drills have several key advantages over regular electric drills:

-

They are more powerful, significantly decreasing mixing times and contributing to faster project completion.

-

They have adjustable speeds, allowing for productivity adjustments to align with different project volumes.

-

They can output up to 1,800 lbs per hour, making them highly efficient.

-

For example, the M18 Fuel Mud Mixer is capable of mixing up to 15 buckets on a single M18™ REDLITHIUM™ battery charge, demonstrating the time and effort efficiency of mixer drills.

Consistent Mixing Results

Another significant benefit of using a concrete mixer drill is the consistency of the results. When mixing concrete by hand, achieving a uniform and homogeneous mix can be challenging. However, a concrete mixer drill’s mechanical action ensures a more uniform mix, reducing the risk of inconsistencies.

Ensuring an even distribution of ingredients, a concrete mixer drill facilitates optimal chemical reactions and consistent material performance. It maintains a uniform water-to-cement ratio for each batch, which is vital for the resulting concrete’s strength and durability. Moreover, using a concrete mixer drill reduces the occurrence of undermixing or overmixing, preventing issues like weak concrete or mix components separation.

Versatility

Mixer drills are not just for mixing concrete; they are tools of versatility. They are designed to mix a range of materials, from paints and plaster to grout and plaster, featuring appropriate paddles for different viscosities and material types.

With various mixing directions, a concrete mixer drill can handle different material densities. For instance, it can perform:

-

Bottom-up mixing for thick mixtures with high viscosity, like mortar

-

Top-down mixing for thin materials

-

Adjust rotation speeds to match the material density

Adjustable position mixers with multi-blade options offer the flexibility required for mixing substances of varying consistencies, ensuring properly mixed batches irrespective of size.

Selecting the Right Drill for Your Needs

Now that we’ve established the benefits of using a concrete mixer drill, the next step is to choose the right one for your needs. This choice depends on several factors, including power and torque requirements, chuck size compatibility, and speed control features.

For example, a 6 amp, 1/2” drill with a maximum speed of 0-900 rpm is recommended for mixing applications like drywall joint compound. We will go into these factors in more depth.

Power and Torque Requirements

For efficient mixing, a mixer drill should ideally generate at least 1,300 watts of power to handle heavy materials such as concrete. The power and torque requirements for mixing depend on the viscosity and volume of the concrete, with thicker mixes demanding more power and torque to achieve the necessary consistency.

Heavy-duty concrete mixer drills can manage larger volumes with reduced effort, contributing to a more efficient workflow and preventing motor strain often seen in ordinary drills. Some benefits of using a professional-grade concrete mixer drill like the DEWALT DW130V include:

-

Powerful motor for demanding job site applications

-

Increased efficiency and productivity

-

Reduced strain on the motor

-

Durable construction for long-lasting use

These features make professional-grade concrete mixer drills a valuable tool for any construction or renovation project.

Moreover, the higher torque provided by dedicated mixer drills allows for better handling of heavy sustained loads, integral for maintaining optimal mixing performance.

Chuck Size Compatibility

Choosing the correct chuck size is essential for ensuring compatibility between the concrete mixer drill and the paddle mixer attachments. Most concrete mixer drills include a 1/2” keyed chuck, which allows for broad compatibility with various mixer paddle attachments. This compatibility ensures the efficient and effective functioning of your mixer drill.

Speed Control Features

The versatility of a concrete mixer drill is further enhanced by its speed control features. These include options such as load speed adjustments, dual-speed settings, and multiple speed control methods like dials, triggers, and lock-on buttons. This adaptability is crucial for handling different materials.

The benefits of mixers with adjustable speed include:

-

Control over splatter and ensuring the quality of the mixture

-

Ability to cater to the consistency and volume of various materials

-

Reducing operator fatigue with lightweight and portable mixers

-

Suitable for prolonged use on job sites or DIY projects

For instance, professional-grade concrete mixer drills can reach over 700 RPM, but even mixers and drills with a capability of 500 RPM are sufficient for most mixing tasks, ensuring consistent performance and high-quality batches.

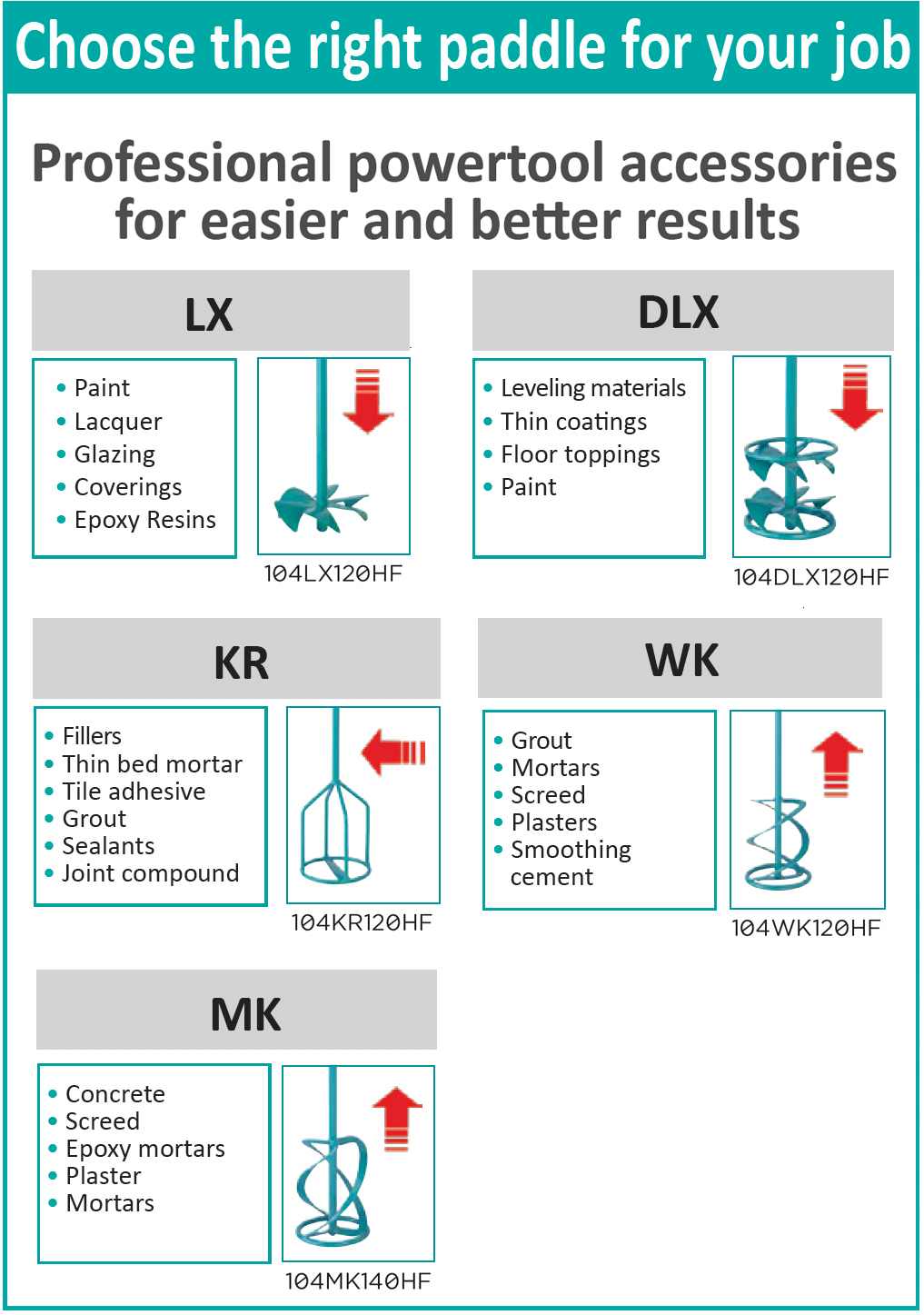

Essential Paddle Mixer Attachments

Matching the correct paddle to the concrete mix can lead to time savings and increased efficiency during the mixing process. There are different types of paddle mixer attachments, each serving a unique purpose. These include helical paddles, twin-blade paddles, and specialty paddles. Quick-change systems like HEXAFIX enable toolless switching between various paddles for different mixing tasks.

We will explore these paddle types more thoroughly.

Helical Paddles

The shape of the paddle in a concrete mixer drill is crucial for quick and efficient, mixing concrete together. Helical paddles are designed to ensure a smooth, homogenous concrete mixture by thoroughly combining materials and reducing the chance of creating air bubbles in the mixture.

Twin-Blade Paddles

Twin-blade paddles are designed to enhance the thoroughness of the mix. The increased surface area and time of twin-blade paddles in contact with the material makes the blending process more efficient, significantly reducing the time required for mixing.

Specialty Paddles

Selecting the correct paddle based on the viscosity of the material is crucial for mixing efficiency and to prevent problems such as clumping or premature hardening, particularly when dealing with reaction resin mixtures. Specialty paddles, designed in various shapes, are optimized for specific materials and mixing actions, playing an integral role in the mixing process.

Tips for Safe and Effective Mixing

Operating a concrete mixer drill requires certain safety measures and effective mixing techniques to ensure not only the quality of the mixture but also the safety of the operator. Following the manufacturer’s instructions for setup, safety checks, loading materials, and cleaning can prevent damage to the machine and ensure operator safety.

We will discuss these access tips further, with your permission, during the http checkout process.

Proper Gear and Equipment

When operating a concrete mixer drill, it’s crucial to wear the proper personal protective equipment to mitigate risks such as cement dust and noise exposure. This includes:

-

Safety glasses

-

Gloves

-

Safety boots

-

Hearing protection

-

Respirators

Due to concrete’s acidic nature and the silica it contains, waterproof, alkali-resistant gloves and boots, as well as appropriate respiratory protection products, are necessary.

Always ensure that your protective gear fits correctly and is in good repair to maintain safety standards.

Mixing Techniques

Utilizing proper mixing techniques is key to achieving a high-quality paint mixture. Applying the correct technique with the right paddle design prevents mix issues such as clumping and air bubbles.

Ensuring a stable base and proper measurement of materials for the mix are critical in achieving an optimal and consistent concrete mixture.

Maintenance and Care

Regular maintenance and care following manufacturer guidelines ensure the longevity and safety of the mixer drill. Daily cleanings by ensuring the mixer is free from residual concrete before and after use is essential.

Weekly inspections and adjustments, along with monthly examinations, help keep your mixer drill in optimal condition.

Popular Options on the Market

Having understood the benefits, selection criteria, and safety measures involved in using a concrete mixer drill, let’s explore some popular options on the market. Options like:

-

Makita DS4000

-

Makita DS4012

-

Bosch GBM9-16

-

DEWALT DW130V

Stand out, each bringing unique features and advantages to handle various mixing tasks, including those that involve a bucket and small batches.

Product 1: Features and Benefits

The Makita DS4000 is renowned for its robust construction, including the class’s most durable chuck, casing, and internal gears, complemented by a sizable 12-inch handle for enhanced control and comfort.

The Xo 55 R duo concrete mixer drill features powerful counter-rotating paddles that deliver the best mixing results quickly and efficiently across different viscosities and materials. Products like these address the challenges of underpowered drills by offering more powerful motors and mixers with ergonomic designs that reduce muscle strain and fatigue during extended mixing tasks.

Product 2: Features and Benefits

The Makita DS4012 mixing power drill provides professional-grade and heavy-duty capabilities at a fair price. DEWALT provides a 3-year limited warranty, 1-year free service, and a 90-day satisfaction guarantee for the DW130V mixing drill.

Weighing only 7.5 lbs., the DW130V is the lightest mixer drill in its class, designed to boost user productivity while minimizing tool fatigue.

Product 3: Features and Benefits

The Bosch GBM9-16 boasts a robust 9 amp motor teamed with a 16mm chuck, compatible with a diverse array of attachments for extensive mixing and drilling tasks. The Collomix Xo4 is a professional two-gear power mixer that’s perfect for mixing an extensive array of materials, able to mix quantities up to 17 gallons. With its two-speed variable electric motor and a quick-couple or M14 fitting, the Xo4 ensures fast tool change-over, enhancing efficiency in mixing applications.

The Milwaukee M18 Fuel Mud Mixer introduces an adjustable 180° handle with 16 settings, optimizing user ergonomics and comfort for difficult mixing tasks.

Summary

In summary, a concrete mixer drill is an invaluable tool in the construction industry, providing time and effort savings, consistent mixing results, and versatility. When choosing a mixer drill, it’s crucial to consider power and torque requirements, chuck size compatibility, and speed control features. The use of appropriate paddles is also essential for efficient mixing. Lastly, always remember to use proper safety gear, apply effective mixing techniques, and conduct regular maintenance for safe and effective operation.

Certified MTP offers a full line of Cement Mixers, Stationary Cement Mixers, Concrete Mixers, Concrete Cement Mixers, Cement Mixer Tubs, Concrete Mixer Drill, and Portable Concrete Mixers.

Frequently Asked Questions

What kind of drill do you use to mix concrete?

To mix concrete, you should use a hammer drill with a masonry bit, as masonry bits work differently than wood bits. In addition, a diamond bit drill can also be used to cut and get into concrete.

What is the best tool to mix concrete with?

The best tool to mix concrete with is a power tool, which reduces the amount of physical labor required for the task. Using tools such a shovel or spade manually can be physically demanding and may not provide an even mixture.

Can a hammer drill be used as a mixing drill?

Yes, a hammer drill can be used as a mixing drill by turning off the hammer function and using a mix beater that fits the drill arbor.

Is a concrete mixer worth it?

Yes, if you frequently pour concrete, purchasing your own mixer can pay off within just a few big projects. If you only do occasional small jobs, renting a concrete mixer should be enough to get by.

What are the benefits of using a concrete mixer drill?

Using a concrete mixer drill saves time and effort, ensures consistent mixing results, and is versatile in handling various materials and viscosities, making it a valuable tool for construction and DIY projects.

Related Blogs for Concrete Mixer Drill:

Concrete Mixer Trailer: Get Ready For Your Project

Top Durable Concrete Drum Options for Efficient Mixing

Best Portable Concrete Mixers of 2024: Mixing Mastery

Best Cart Away Mixer for Your Construction Needs

Concrete Mixer Large: Maximize Mix for Construction Projects

Cement Mixer Tub Options for Efficient Concrete Preparation

Gilson Cement Mixers: Durable Solutions for Concrete Mixing

Mixer for Concrete: The Ultimate Guide to Choosing

Hand Mixer for Concrete: Your Tool for Cement Mixing

How a Drill Mixer Can Streamline Your DIY Projects

Best Concrete Mixer for Drill Transforms Construction Work

Understanding Cement Mixer Cost: A Pricing Guide

We recommend the Stationary Concrete Mixer for most residential and small construction projects.