Concrete Vibration Tool: Ultimate Guid Maximize Efficiency

Selecting the proper concrete vibration tool is crucial for the integrity of your construction project. This guide cuts straight to the chase, giving you the necessary insights to determine the ideal concrete vibrator for your specific needs. From understanding different types to maximizing tool efficiency, we’ve got you covered.

Key Takeaways

-

Different types of concrete vibration tools, internal, external, and surface vibrators, are designed for specific construction applications, and their efficient use crucially enhances the strength, density, durability, and appearance of concrete structures.

-

Choosing the right concrete vibration tool involves considering factors such as power source, job size, type of pour, and vibrator head size, with the aim of effectively consolidating concrete and removing air pockets to ensure the quality and strength of the structure.

-

When using a concrete vibration tool, safety is paramount; proper handling, protective gear, regular equipment maintenance, and adherence to safety precautions are essential for optimal performance and longevity of the tool.

Understanding Concrete Vibration Tools

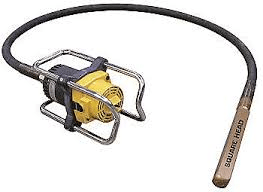

Comprising three main components – the motor, the whip, and the head, the concrete vibrator is both simple and complex. Vibrations are created at high frequencies by the motor, which are then transferred through the whip to the head. The head, built for resilience, may contain an in-built motor for consistent vibrational force.

These vibrations are then applied to freshly poured concrete, shaking it to eliminate air bubbles. This process, called vibrating, typically lasts between 5 to 15 seconds per interval. It’s repeated until no more bubbles escape, signifying that all the trapped air pockets have been removed.

This consolidation process plays a key role in achieving a more durable and denser finished structure, allowing time for positive change.

Types of Concrete Vibration Tools

Concrete vibration tools are not one-size-fits-all tools. There are three main types used in construction: internal, external, and surface vibrators, each with its specific applications. Internal vibrators, also known as immersion vibrators, are inserted into wet concrete, vibrating it around them. These vibrators are particularly suitable for architectural, dam, mine, and well engineering projects due to their high frequency and ease of mobility.

On the other hand, external vibrators are attached to the outside of concrete forms, agitating the concrete to remove air pockets and ensure a high-quality surface finish. Ideal for narrow spaces, pre-cast concrete, and areas where internal vibration isn’t feasible, external vibrators are your go-to tool for these specific situations.

And then there are surface vibrators. These products are placed directly on top of poured concrete, creating a smooth surface on floors, ceilings, and pavements. However, they’re not recommended for use with thick slabs or large volumes.

The Role of Concrete Vibrators in Construction

The role of concrete vibration tools in construction is paramount. They are crucial in:

-

Eliminating air pockets, which can compromise concrete quality, especially in complex structures with rebar columns

-

Reducing concrete density and load-bearing capacity

-

Achieving uniform compaction

Therefore, the use of concrete vibrators is critical to ensuring the quality and strength of concrete structures.

By eliminating these pockets, concrete vibration tools enhance the strength, density, durability of the final product, and bolster the bond with reinforcement steel – all critical attributes in construction. Handling a concrete vibrator properly can prevent construction issues such as cold joints and the formation of cavities, both of which are potential failure points.

Even the aesthetics of your project can benefit from the use of a concrete vibrator. Vibration techniques like internal vibration help produce a smooth surface, which significantly enhances the appearance of the finished project. However, using a poorly matched vibrator can hinder the consolidation process, leading to substandard concrete quality.

Selecting the Right Concrete Vibration Tool

Selecting the appropriate concrete vibration tool parallels choosing the perfect pair of shoes; it must be suited to the task at hand. The power source, job size, and type of pour are just a few of the factors that can influence the selection. Whether you’re working on a small home renovation project or a large-scale commercial construction, selecting the right concrete vibration tool can make all the difference to the quality and efficiency of your work.

So, what is the process of aligning the tool with the task? And what considerations should guide your decision? Let’s delve deeper into these questions and equip you with the knowledge you need to make an informed decision.

Factors to Consider

The power source is a key factor when selecting a concrete vibration tool. Gas-powered vibrators offer portability and can work without electrical power. However, they may require more maintenance and have limitations regarding the shaft length and head size. Electric models, on the other hand, provide higher RPMs, crucial for effective air pocket removal, and can use longer whips compared to gas vibrators. In certain situations, environmental restrictions may limit the use of gas-powered equipment, nudging you towards electric models.

The size of the construction job also influences the choice of a concrete vibrator. Smaller jobs might require more compact concrete vibrators, whereas larger jobs necessitate equipment capable of handling higher volumes of concrete efficiently. For example, the diameter of a concrete vibrator should be roughly one-quarter of the wall’s thickness, determined by the structure’s height and width.

The type of pour, such as wall, floor, column, etc., also dictates the required vibrator head size. Some factors to consider when choosing the vibrator head size include:

-

Smaller heads are needed for shallow forms

-

Larger heads are necessary for forms with wider spacing due to their size

-

Other factors include the distance to the electrical source, the amount of reinforcing steel, job specifications, concrete slump, and mix design.

Matching the Tool to the Job

Now that we’ve considered the various factors, let’s focus on how to match the tool to the job. Selecting the appropriate diameter of a concrete vibrator is pivotal. Typically, a 2 to 2 and one-half inch diameter is sufficient for most building concrete. However, larger vibrators might be needed for stiffer mixes and bigger aggregate sizes.

To ensure effective air removal and concrete consolidation, a systematic insertion and removal pattern must be followed using the concrete vibrator. Here are the steps to follow:

-

Determine the effective consolidation radius of the vibrator head.

-

Identify the optimal distance between insertions, typically 1.5 times the radius. Watch for air bubbles breaking the concrete’s surface to determine this distance.

-

Quickly dip the vibrator into the concrete.

-

Withdraw the vibrator at a rate of approximately one inch per second.

-

Ensure that air bubbles can rise and the hole closes properly behind the vibrator.

By following these steps, you can ensure proper air removal and concrete consolidation.

Frequency and amplitude are also crucial considerations. The frequency and amplitude of a concrete vibrator should be selected based on the concrete’s slump, additives, aggregate sizes, and the consistency of the mixture, as these factors vary with each construction case. Over-vibration can lead to issues like segregation or diminished entrained air, so it’s vital to strike the right balance.

Shipping and Delivery of Concrete Vibrators

The subsequent important step is getting your chosen concrete vibrator delivered to your doorstep. Many concrete vibrators come with free shipping and include no hidden fees, easing the cost for customers. To assure the quality of the product, vendors often perform a complimentary pre-inspection before shipping or dispatching a concrete vibrator. This is followed by efficient logistics processing, typically resulting in a delivery timeframe of 3-5 days.

But what encompasses the ordering process? And what do the shipping methods and timeframes entail? Let’s find out.

Ordering Process

The ordering process for a concrete vibrator is designed to be as easy and smooth as possible. It begins with a thorough pre-inspection of the vibrator to ensure its quality before it’s dispatched. This service is often provided free of charge by many vendors, adding an extra layer of assurance for customers.

Throughout the process, efficient logistics teams work hard to process and dispatch your order as swiftly as possible. This quick and efficient service ensures that the concrete vibrator reaches you in a timely manner, ready for easy use in your construction project.

Shipping Methods and Timeframes

Once your order is processed, it’s time for shipping. Understanding the shipping methods and delivery times is crucial for timely receipt of your concrete vibrator. Reliable delivery partners and secure packaging are employed to ensure the safe arrival of your order.

The typical delivery timeframe for orders of concrete vibrators is between 3 to 5 days following order processing. Some sellers may even offer expedited order processing and dispatching, ensuring you receive your products within the stated delivery times.

Using Your Concrete Vibration Tool Safely and Effectively

Securing the right concrete vibrator and receiving it promptly are only the initial steps. The subsequent critical stage entails using it both safely and effectively. Proper operation of a concrete vibrator not only ensures optimal performance but also extends the life of your tool.

When operating a concrete vibrator, safety takes precedence. Proper management of cords and hoses, keeping them clear of the work area, is pivotal to prevent tripping hazards. But safety precautions go beyond just managing cords and hoses. Let’s delve deeper into this topic.

Safety Precautions

Operating a concrete vibrator involves certain risks, which can be mitigated by adhering to safety precautions. For starters, it’s crucial to wear head protection, such as a hard hat, to prevent injury from falling objects. Your eyes, too, need protection from dust and other flying particles. Wearing full-cover goggles or safety glasses with side shields can help protect your eyes during operation.

Your skin also needs protection from chemical burns when handling fresh concrete. Here are some tips to protect your skin:

-

Wear waterproof gloves

-

Wear long-sleeved shirts and long pants

-

If you’re standing in fresh concrete, wear rubber boots high enough to prevent concrete from getting inside them.

Lastly, always ensure that all safety devices and guards on the concrete vibrator are in place and functioning properly before use.

Maintenance Tips

Appropriate maintenance can extend the lifespan of your concrete vibrator. Regular checks should be carried out on the vibrator head for any signs of damage or wear. Ensure it’s replaced when necessary to maintain efficiency. Power cords and plugs should be inspected for cuts and frays, and any visible damage should be addressed immediately to prevent electrical hazards.

Regular oil lubrication is also critical for the concrete vibrator. Use the right type of oil, such as paraffinic-based oils, to prevent overheating. The correct amount of oil can be identified by a fine oily film inside the exhaust port, which confirms adequate lubrication without excess. Furthermore, before long-term storage, it’s advisable to lubricate the internal components to prevent rust and ensure the concrete vibrator’s functionality isn’t compromised when next used.

Lastly, storing the concrete vibrator in a dry and secure location can protect it from corrosion and unintentional damage when it’s not in operation. Ensure that the environment around stored vibrators is well-managed, such as positioning exhaust deflectors downwards to prevent the accumulation of water or dust.

Making Changes and Returning Items

There may be occasions when you need to return or exchange your concrete vibrator. Understanding the return policy and the steps involved is crucial to ensure a smooth process. The return policy for concrete vibrators typically includes a specific period within which the item can be returned, often ranging from 30 to 90 days after purchase. However, keep in mind that restocking fees may apply for returned concrete vibrators, which can vary from 10% to 25% of the purchase price depending on the vendor’s policy.

So, what is the procedure for returning or exchanging a concrete vibrator? Let’s find out.

Return Policy

Most companies require the concrete vibrator to be in unused condition and in its original packaging for a return to be accepted. The item should include all the original parts and accessories to qualify for a full refund. Note that custom-made or special-order concrete vibrators may be non-returnable items or subject to a more stringent return process.

Steps for Returning or Exchanging

To initiate a return or exchange, you must contact the retailer or manufacturer’s customer service to obtain a Return Merchandise Authorization (RMA) number. Proof of purchase, such as a receipt or order number, is typically required when requesting a return or exchange.

The refund or exchange is processed after the return is received and inspected, which may take several days to a few weeks based on the company’s policies.

Summary

In conclusion, concrete vibrators are an indispensable tool in the construction industry. By eliminating air pockets, they enhance the durability, strength, and appearance of concrete structures. With different types available, choosing the right concrete vibrator depends on various factors, including the power source, job size, and type of pour.

Using your concrete vibrator safely and effectively is just as crucial as choosing the right one. Following safety precautions and regular maintenance can prolong your tool’s lifespan and ensure optimal performance. And if you ever need to return or exchange your tool, understanding the vendor’s return policy and the steps involved can save you a lot of hassle.

Frequently Asked Questions

Can you vibrate concrete by hand?

Yes, for small-area concrete pouring, you can vibrate concrete by hand using a hand screed or concrete hammer to eliminate air bubbles. This can achieve the same effect as using a mechanical vibrator.

What machine is used to vibrate concrete?

A concrete vibrator is the machine used to vibrate concrete, coming in various sizes and power sources for construction purposes.

What thickness should you vibrate concrete?

You should vibrate concrete with external vibrators on forms less than 6 inches thick. This is ideal for areas where surface quality is important or when working with concrete containing rebar.

What does a concrete vibrator do?

A concrete vibrator eliminates air bubbles and air pockets in concrete, resulting in stronger concrete.

What are the main types of concrete vibrators?

There are three main types of concrete vibrators: internal, external, and surface vibrators, each serving specific applications in construction.

Related Blogs to Concrete Vibration Tools:

Concrete Curing Underwater: Challenges

Consistency of Concrete: Measure, Importance and Workability

8 Concrete Innovations Changing the Future of Construction

28 Days to Testing Concrete for Strength

Concrete Testing Product: A Better Process

Concrete Cure Box for Cylinders: The Benefits