Hammer Mill: Unlocking the Potential of Material Reduction

Have you ever wondered how certain materials are reduced to smaller pieces for easier processing? The answer lies in the power of hammer mill machines! These versatile machines are used for particle size reduction in various industries, from agriculture to food waste and rock crushing. In this blog post, we’ll delve into the world of hammer mills, explore their components, examine different types, and discuss their applications and industries. By the end, you’ll have a solid understanding of these hammer mill machines and their potential for material reduction.

Key Takeaways

-

Mills are machines that use high-speed hammers to reduce materials into smaller pieces for primary, secondary, or tertiary crushing.

-

Components of a mill include material inlet, casing/housing, shaft/drum with hammers and screen powered by an electric motor.

-

Hammer mills can be tailored to suit various industries such as wood processing and food waste rendering while regular maintenance is necessary for optimal operation and safety.

Understanding Mills

Mills, also known as wood hammer mills, are machines that use high-speed hammers to crush and grind materials into smaller pieces, suitable for primary, secondary, or tertiary crushing. They are designed for material reduction and operate in a grinding chamber where the material is fed into the machine. From fibrous materials to friable materials, a wood hammer mill or mills are capable of reducing particles to less than 0.08 inches or smaller than 10 US mesh.

Modern hammer mills utilize electric motors for power, a far cry from their water-powered trip hammer mill ancestors.

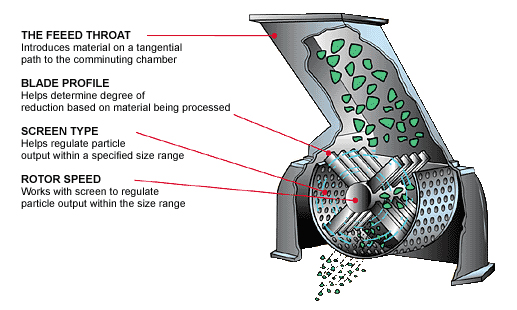

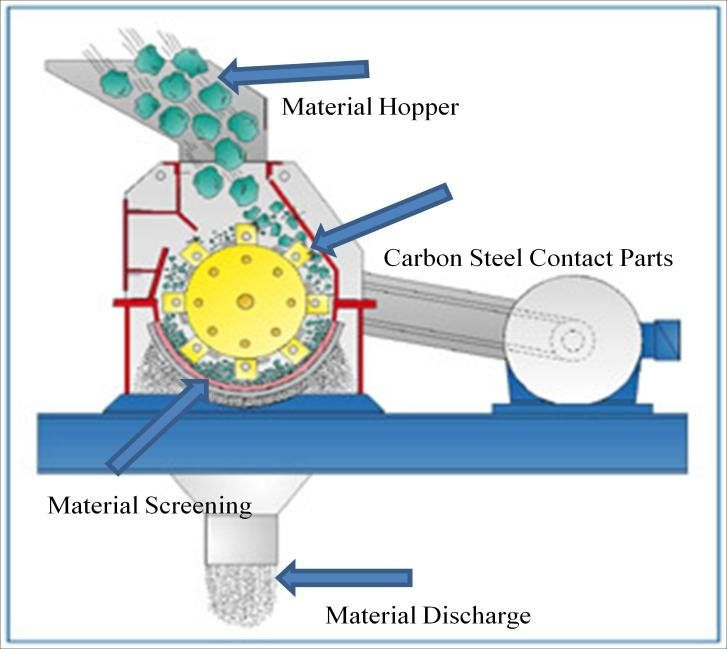

Components of a Mill

A mill consists of several key components: a material inlet, a heavy-duty casing/housing, a rotating shaft or drum, hammers, a screen, and a motor. The material inlet serves as the entry point for the material to be processed, which can include various materials such as printed circuit boards.

The heavy-duty casing/housing protects the internal components, including the rotor construction. The rotating shaft or drum is the primary component of the hammer mill, responsible for its operation; it rotates at high speeds to break down the material into smaller particles with the help of perforated screens.

How Mills Work

The mechanism of mills involves:

-

Hammers shredding material fed into the feed hopper

-

Particle size reduction determined by the screen or air flow system

-

All housed within a rugged construction

The hammers are powered by electric motors, which rotate the rotor at high speeds, creating a shearing action that breaks down materials into smaller pieces.

This allows mills to effectively process a variety of materials, including wood, feed, grain, and more.

Types of Mills

Hammer mills come in various types, designed to suit different applications and industries. There are wood hammer mills for processing wood waste, grain and corn hammer mills for distilleries, and industrial hammer and milling grain crushers for various industries, making them suitable for most materials.

Each type of mill is tailored to efficiently process specific materials, ensuring optimal results in size reduction.

Wood Mills

Wood mills, or wood hogs, are designed to process wood and fibrous waste without the need for high-maintenance knives. These heavy-duty machines, like the wood hammer mill machine from Stedman Machine, feature a rotor powered by an electric motor, to which several hammers are affixed. The hammers reduce the wood material into smaller particles by striking it at high speeds.

Wood hammer mills are frequently utilized in various industries, including:

-

Wood pellet production for fuel pellets and animal bedding

-

Processing other materials, such as agricultural and fertilizer processing

-

Rock and aggregate crushing

-

Food waste and rendering

Grain and Corn Mills

Grain and corn mills are machines designed for milling grain, such as corn, wheat, barley, and other agricultural materials. They are utilized in a variety of industries, including:

-

Grain processing

-

Brewing

-

Distilling

-

Feed mills

These mills operate by reducing the size of raw materials via repeated blows or impacts, resulting in finely ground or crushed particles. By processing grains and corn, these hammer mills contribute to the production of various products, from bread to distilled beverages.

Industrial Mill Crushers

Industrial mill crushers are machines that utilize a series of rotating hammers to crush and disintegrate various materials. They are frequently utilized in the aggregate, mining, and industrial sectors for reducing the size of materials, such as limestone, coal, and ores.

These crushers operate by using the force of the hammers to break down and disintegrate materials, with the hammers connected to a shaft that rotates at high speeds. Industrial hammer mill crushers are highly efficient, dependable machines that can rapidly reduce the size of materials, making them an ideal option for many industries.

Applications and Industries

Mills are used in a wide range of industries and applications, showcasing their versatility and adaptability. They excel in rock and limestone crushing, food waste and rendering, and agricultural and fertilizer processing, among others.

As mills can be tailored to meet the specific requirements of each industry and application, they prove to be an invaluable tool for material reduction.

Rock and Aggregate Crushing

One of the primary applications of mills is in rock and aggregate crushing. Industries such as the mineral and mining industry rely on hammer mills for the efficient reduction of materials like limestone, coal, and ores.

The ability of mills includes:

-

Breaking down large rocks, boulders, or gravel into smaller pieces

-

Facilitating the production of various construction materials

-

Extracting valuable minerals and elements from ores.

Food Waste and Rendering

Food waste and rendering applications require durable and efficient mills for processing waste and rendering byproducts. Industrial hammer mill crushers are commonly employed for this purpose, as they are capable of processing a wide range of materials and ensuring a high concentration of processed waste.

Hammer mills, by reducing food waste and rendering byproducts to smaller particles, contribute to a more sustainable and environmentally friendly approach to waste management by facilitating easier and more efficient processing.

Agricultural and Fertilizer Processing

Agricultural and fertilizer processing involves the use of mills for various tasks, such as lime crushing, animal feed processing, and grain corn reduction. Hammer mills play a crucial role in the production of pharmaceuticals, toothpaste, paint, paper, caulking, and glass, due to their ability to process limestone into smaller, more manageable particles.

Additionally, they are utilized in the production of animal feed, ensuring that feed and livestock receive the nutrients they need for healthy growth and development.

Selecting the Right Mill

When selecting the right mill for a specific application or industry, several factors must be considered, such as material type and hardness, output size requirements, and application and industry needs.

Taking these factors into account helps identify the most suitable hammer mill, ensuring optimal results and efficient material reduction in finished product.

Material Type and Hardness

The material type and hardness of the material being processed play a significant role in determining the appropriate hammer mill design and configuration. Different materials require different types of hammers and grinding plates, with harder materials necessitating more powerful motors and larger hammers, while softer materials require less powerful motors and smaller hammers.

The most suitable mill can be selected by considering the material type and hardness, which ensures optimal performance and efficiency.

Output Size Requirements

Output size requirements also play a crucial role in selecting the right mill, as different output sizes necessitate different types of hammers and grinding plates. Coarser output sizes require larger hammers and more powerful motors, while finer output sizes require smaller hammers and less powerful motors.

Identifying the most suitable mill involves taking output size requirements into account, ensuring the achievement of a high speed inside the desired particle size.

Application and Industry Needs

Lastly, it is essential to consider the specific application and industry needs when selecting a mill, as different applications and industries necessitate distinct types of hammers, grate bars, and grinding plates.

For instance, food waste and rendering require more powerful motors and larger hammers, while agricultural and fertilizer processing require less powerful motors and smaller hammers.

Understanding the specific requirements of the application and industry aids in selecting the most suitable hammer mill, which ensures optimal results and efficient material reduction.

Maintenance and Safety

Proper maintenance and safety precautions are essential for the efficient operation and longevity of hammer mills. Regular maintenance, such as checking and replacing hammers, screens, and other components, helps ensure that the mill unit remains in peak working condition.

Additionally, observing safety precautions, such as proper training, wearing protective equipment, and adhering to safety guidelines, helps prevent accidents and injuries.

Regular Maintenance

The efficient operation and longevity of mills depend on regular maintenance. This includes checking and replacing hammers, screens, and other components as needed. Additionally, magnets should be examined and cleaned periodically to ensure their optimal performance.

Lubricating moving parts and cleaning and lubricating bearings are also essential steps in maintaining the proper functioning of the hammer mill.

Safety Precautions

The safe and efficient operation of mills hinges on safety precautions. These include inspecting the flexibility of rotors for signs of jamming, crushing, or rubbing, and avoiding the use of bolt-on tips in swing hammer designs to prevent damage and dislodging.

Proper protective clothing, such as long pants, closed-toe shoes, and long-sleeved shirts, should be worn when operating hammer mills. Additionally, operators should follow the proper operating procedures and safety precautions as outlined in the manual.

Case Studies and Customer Testimonials

Valuable insights into the success of mills in various applications, such as turn-key ore processing systems and wood hog operations, can be drawn from case studies and customer testimonials.

By showcasing real-world examples of how mills have been effectively utilized, these stories can help demonstrate the potential of these machines for material reduction in diverse industries and applications.

Turn-Key Ore Processing System

Turn-key ore processing equipment systems often include the following equipment as part of their efficient material size reduction processes:

-

Jaw crusher

-

Hammer mill

-

Ball mill

-

Shaker table

-

Spiral classifier

These systems are designed for ore processing.

The combination of these components has demonstrated impressive results in real-world applications, such as one case where the combination of a jaw crusher, hammer mill, and shaker table produced even better results than those advertised by the manufacturer.

Wood Hog Success Story

Wood hog success stories highlight the effectiveness of wood mills in processing wood and other fibrous materials from waste. For example, one company utilized a wood hog to process wood waste into wood chips, which were then used as fuel for a biomass power plant.

Another example is a company that employed a wood hog to process wood waste into wood pellets, which were then used as animal bedding. These success stories showcase the versatility and efficiency of wood mills in various applications and industries.

Summary

In conclusion, mills are powerful and versatile machines that play a crucial role in material reduction across various industries and applications. By understanding their components, types, and working mechanisms, we can better appreciate their potential for efficiently processing a wide range of materials. Proper maintenance and safety precautions ensure the longevity and optimal performance of these machines, while case studies and customer testimonials demonstrate their success in real-world applications. Whether it’s processing wood waste, crushing rocks, or reducing food waste, hammer mills are invaluable tools for transforming raw materials into useful and valuable products.

Certified MTP has an elite selection of lab solutions, showcasing industry-leading brands including Flasks, Beakers, Pipettes, & Graduated Cylinders, Benchtop & Economy Laboratory Mills, Jar Mills, Pulverizers and Lab Crushers, and the popular Hammermill Coal Crusher, Larger Feeds Up To 6in

Frequently Asked Questions

What is a mill used for?

Mills are a type of size reduction equipment used to break down oversized granular materials, such as rock and mineral ores. They provide reasonably uniform size reduction while ensuring a reliable operation, and are often used to shred materials into fine particles or crush pieces of hard, frangible materials.

What is the difference between a grinding mill and a hammer mill?

Grinding mills use a more precise process, resulting in more consistent size and shape of the material, whereas other mills are less precise, using swinging blades to create an inconsistent finished product size.

Can a mill be considered as corn mill?

Yes, a Mill can be considered as a corn mill as it is designed to process, grind and sieve cereal grains such as corn.

What is a mill in a distillery?

A mill in a distillery is an apparatus that uses hardened steel hammers that spin centrifugally around a motor-driven shaft inside of a screen, to pulverize grain and force it through the screen, resulting in a finer grist.

What is mill crusher?

A mill crusher is a device that is designed to pulverize, grind and crush material using hammer blows at high speed, shattering and disintegrating it in the process.