How is Concrete Tested for Strength and Durability?

Concrete must be strong and reliable, but how is concrete tested for strength? In this guide, we’ll uncover the crucial tests that determine whether concrete can handle the heavyweight of our infrastructure. From crushing tests that measure compressive strength to sophisticated methods that assess integrity without damage, these processes are fundamental for safe and sound engineering. Join us as we reveal how these tests work and why they’re a cornerstone of construction quality.

Key Takeaways

-

How is Concrete Tested for Strength and Durability? Regular on-site compressive strength testing using standardized methods like the ASTM C39 is crucial for the quality control of concrete, ensuring it meets safety and durability standards for structural integrity.

-

Tensile and flexural strength tests, alongside non-destructive tests like the rebound hammer and ultrasonic pulse velocity (UPV) methods, offer a comprehensive assessment of the concrete’s resistance to cracking, bending, and underlying damages without compromising structural integrity.

-

Concrete strength is influenced by factors such as mix design, water-cement ratio, curing temperature, and mixing time; advancements in Ultra High-Performance Concrete (UHPC) are enhancing the strength, durability, and sustainability of concrete in construction.

How is Concrete Tested for Strength: Testing

Evaluating a structure’s integrity and load-bearing capacity requires concrete strength testing. It plays an integral role in determining the safe design of structural elements such as columns, beams, and slabs. More than just a simple procedure, strength testing is a critical aspect of construction projects, a strength testing method which verifies that a structure meets the necessary safety and longevity standards.

The load-bearing capacity of concrete is a fundamental aspect to understand. It directly relates to the safety and viability of buildings, bridges, and other infrastructure developments. Regular on-site compressive strength testing embodies a commitment to quality control, confirming adherence to concrete quality standards throughout the construction process. By providing comprehensive strength data, concrete strength testing reassures constructors and stakeholders that the material used meets the necessary criteria for durability and reliability, thus cementing trust in civil engineering practices.

How is Concrete Tested for Strength: The Foundation

Learning how is concrete tested for strength and discovering the evaluation of concrete quality relies on evaluating concrete strength through compressive strength. Assessed through the compressive strength test, this measure is crucial in ensuring stability and determining if a concrete mixture meets the needs of a specific job. The test is the standard method for determining the strength of concrete, providing valuable data on the material’s ability to resist compression, typically measured in pounds per square inch (psi).

Cylindrical Specimen Compression Test

The Cylindrical Specimen Compression Test determines the compressive strength of concrete samples. The test involves applying a continuous load over a cylindrical specimen until failure, following a standardized test procedure. Concrete cylinders used in this testing commonly have dimensions of 150mm by 300mm or 100mm by 200mm, and their diameter is measured at two perpendicular directions at mid-height for accuracy.

To calculate compressive strength of multiple concrete samples, divide the maximum load the specimen sustained before failure by its cross-sectional area. These compressive strength test results, along with information about the specimen’s casting date, age, testing date, and any detected defects, are meticulously recorded. This testing method is vital to ensure that the concrete can endure the forces it will face over its lifespan.

ASTM Standard C39 Compliance

In the construction industry, the ASTM C39 standard plays a crucial role. It ensures that breaking cylindrical concrete specimens meets rigorous specifications for strength and serves a critical role in quality control. The compressive strength of cylindrical concrete specimens is determined by following the ASTM C39 procedure which dictates factors such as the loading rate and requires detailed reporting of results including maximum load and fracture type.

ASTM C39 specifies specimen dimensions, requiring the cylinder’s diameter to be at least three times the nominal maximum size of coarse aggregate, and that diameters must be consistent within 2% for test validity. Technicians handling ASTM C39 standardized tests must conform to Practice C1077 requirements, and due to potential sudden specimen ruptures, strict safety precautions should be observed.

How is Concrete Tested for Strength: Tensile and Flexural

While compressive strength is a critical measure of concrete quality, it isn’t the only factor to consider. Tensile and flexural strength tests assess the material’s resistance to cracking and bending. These tests utilize indirect methods like the Split Cylinder Test and Flexure Test, providing a comprehensive understanding of the concrete’s robustness.

Indirect Tensile Strength Testing Techniques

Techniques like the Split Cylinder Test are used for indirect tensile strength testing, providing valuable data on the concrete’s resistance to breaking or cracking under tension. This test involves a Compression Testing Machine, making it a standard method used to test concrete strength and determine the tensile strength of concrete.

During the Split Cylinder Test, the following steps are followed:

-

Plywood strips are used between the specimen and loading platens to uniformly distribute the load and reduce stress concentrations.

-

The test induces a vertical compressive stress and a horizontal tensile stress.

-

The cylinder eventually splits along a vertical plane due to Poisson’s effect.

-

The splitting tensile strength obtained from this test provides a comparison metric for concrete strength.

Center-Point vs. Third-Point Loading

Center-point and third-point loading tests measure concrete’s flexural strength, which is its capability to resist bending or flexural loads. While center-point loading typically results in higher flexural strength, third-point loading is preferred due to its ability to simulate pure bending more effectively by minimizing shear forces in the specimen.

In third-point loading tests like the Flexure Test, a concrete beam is supported at its ends and loaded at one-third span points. For accurate test results, fractures should occur within the middle third of the beam, otherwise, the test is discarded as per standard guidelines.

Non-Destructive Testing (NDT) for On-Site Assessment

Without causing structural damage, non-destructive testing methods allow for on-site assessment of concrete strength. Techniques such as the rebound hammer test and ultrasonic pulse velocity (UPV) methods allow for accurate testing and the estimation of concrete’s mechanical properties while preserving the structural integrity, significantly lowering labor costs and avoiding the risk of damage.

Rebound Hammer Test Method

For quality control, the Rebound Hammer Test or Schmidt Hammer Test is invaluable as it’s a non-destructive method used to estimate concrete strength and identify deteriorated areas. The operating principle of the rebound hammer test involves crushing a spring-driven hammer mass that impacts the concrete surface and then rebounds. The rebound velocity provides an indication of the concrete’s hardness and, therefore, its compressive strength.

To perform the test, the hammer is positioned perpendicularly to the concrete surface; after release, the plunger’s rebound value is recorded, and an average of multiple tests across different locations is used to estimate compressive strength in situ concrete element. Before testing, it is essential to calibrate the rebound hammer, which is typically done by striking a standard reference anvil and recording the rebound values.

The rebound hammer test method is favored for its convenience as it is relatively easy to use, allows for direct onsite testing without the need for laboratory samples, and provides quick results.

Ultrasonic Pulse Velocity (UPV) Test Method

Another non-destructive method for evaluating concrete quality and identifying damages is the Ultrasonic Pulse Velocity (UPV) Test, also known as the ultrasonic pulse velocity method. The test measures the transit time of ultrasonic pulses through concrete, correlating it to the material’s elastic properties and density. The process involves:

-

A meter that calculates pulse velocity

-

Determining the travel time between two transducers using a pulser/receiver

-

Transducer and display devices for data analysis

UPV testing is instrumental for concrete structure evaluation, allowing for the identification of issues with concrete element such as cracks, voids, and assessing the homogeneity and integrity of concrete. However, the accuracy of UPV test results can be influenced by various factors including the quality of concrete, the presence of defects, and the correct application of correction factors taking aggregates and the type of cement into account.

How is Concrete Tested for Strength: Influencing Factors

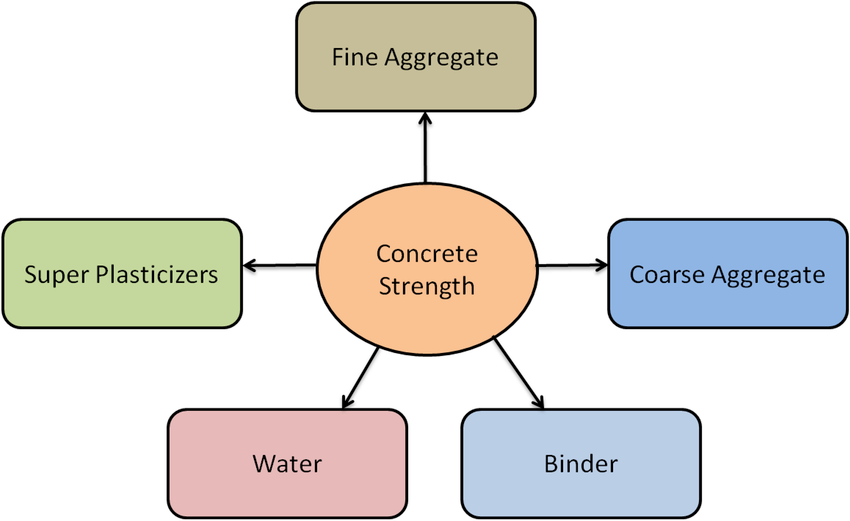

Several factors heavily influence concrete strength. The concrete mix design, which involves optimizing the proportions of cement, aggregates, water, and admixtures, plays a significant role in ensuring desired, strength properties, workability, durability, and cost considerations. The water-cement ratio is another pivotal factor where a proper balance is essential to achieve strong and durable concrete; overwatering dilutes cement paste, reducing strength.

Additionally, environmental conditions, notably temperature, affect the curing process with ideal conditions ranging from 10°C to 30°C. Extreme temperatures require careful management to ensure the concrete develops sufficient strength.

Finally, the optimal mixing time is critical as undermixing leads to inhomogeneity and overmixing can reduce concrete strength due to overhydration and loss of entrapped air.

Ultra High-Performance Concrete (UHPC) Advancements

Advancements in Ultra High-Performance Concrete (UHPC) have been driven by the quest for stronger, more durable, and sustainable concrete materials. UHPC has evolved from an early form known as Reactive Powder Concrete (RPC), which emerged in the 1990s as a significant advancement with high workability, leading to its commercialization. The development of UHPC included innovations such as improving the cement particle packing density and integrating steel fibers to enhance ductility.

Current UHPC advancements aim to:

-

Reduce CO2 emissions and initial costs by incorporating supplementary cementitious materials, hybrid fiber systems, and conventional curing methods

-

Improve both performance and sustainability by integrating innovative materials like calcium sulfaluminate cement (CSA) and calcium aluminate cement (CAC)

-

Diversify into various infrastructure projects due to its superior properties

Despite the challenges of complexity in manufacturing and high production costs, UHPC is becoming increasingly popular in the construction industry.

Utilizing Combined Testing Methods for Accuracy

Combined non-destructive testing methods offer substantial benefits. Techniques such as the rebound hammer test and ultrasonic pulse velocity (UPV) method provide improved accuracy when predicting on-site concrete strength. Calibration with destructive tests is essential for refining the strength estimates obtained from these combined methods, which enhances the overall accuracy.

The utilization of multiple testing methods provides more reliable strength data, particularly valuable in real-world scenarios where detailed records of the concrete may not be available. Some of the testing methods that can be used include:

-

Rebound hammer test

-

Ultrasonic pulse velocity test

-

Core testing

-

Pullout test

Empirical correlations between the rebound number and the strength of concrete require project-specific calibration to reduce the necessity for intrusive tests.

Practical Tips for Ensuring Robust Concrete

Several key practices are involved in ensuring robust concrete. After molding, concrete test specimens should be stored in high humidity conditions and then in water until the testing age is reached, a critical aspect of proper curing. Achieving an appropriate water-to-cement ratio is also crucial for concrete strength. Too much water can weaken the material, whereas too little can reduce workability.

Reinforcing the in situ concrete with materials such as rebar or steel mesh can significantly improve its tensile strength, providing additional support and durability. By combining proper curing techniques, optimal water-to-cement ratios, and reinforcement options, you can ensure the development of robust and durable fresh concrete, which eventually transforms into hardened concrete, suitable for various construction needs.

Summary

From the compressive strength tests to tensile and flexural strength tests, the world of concrete testing is rich and varied. We have learned now about how is concrete tested for strength. Understanding these tests and the factors that influence concrete strength is critical in ensuring the safety, resilience, and longevity of structures. With the advancements in Ultra High-Performance Concrete (UHPC) and non-destructive testing methods, the industry continues to strive for stronger, more sustainable, and efficient materials. As we move forward, the importance of accurate, reliable testing methods remains unchanged, underpinning the trust and confidence we place in the structures that shape our world.

Certified MTP has the largest selection of concrete testing supplies, showcasing industry-leading brands for Concrete Compression Testing Machines, Concrete Air Entrainment Meters, slump testers, Concrete Test Cylinder Molds, and fresh concrete testing equipment.

Frequently Asked Questions

What are the 5 methods of testing strength of concrete?

The 5 methods for how is concrete tested for strength are Rebound Hammer, Penetration Resistance Test, Ultrasonic Pulse Velocity, Pullout Test, and Drilled Core. These methods are commonly used and abide by ASTM standards.

What tool is used to discover how is concrete tested for strength?

The tool used to discover how is concrete tested for strength is the Rebound Hammer, which measures the rebound of a spring-driven hammer after its impact with concrete. It’s a widely used method to assess material properties in construction.

Why is concrete strength testing important?

Concrete strength testing is important because it ensures the safety and longevity of concrete structures by verifying their load-bearing capacity and integrity. It is crucial for quality control.

What factors influence concrete strength?

The mix design, water-cement ratio, environmental conditions, and optimal mixing time are factors that influence concrete strength. Managing these factors carefully is crucial to ensure the development of strong and durable concrete.

What are some advancements in Ultra High-Performance Concrete (UHPC)?

Some advancements in Ultra High-Performance Concrete (UHPC) include improving cement packing density, integrating steel fibers for enhanced ductility, and incorporating supplementary cementitious materials for improved strength and sustainability. These advancements contribute to the overall improvement of UHPC properties.

Related Blogs for How is Concrete Tested for Strength and Durability:

Correctly Measure Cracks and Fissures with a Concrete Testing Product

What is Non-Destructive Testing of Concrete?

Ultrasonic Pulse Velocity Test | Concrete Non-Destructive

Understanding Non Destructive Test: Methods & Applications

Crack Measurement in Concrete: A Guide to Accurate Results

Testing Concrete Cylinders | The Pros and Cons

Concrete Compression Tester | Shop Certified MTP

Compressive Testing: Tests, Procedures, and Results

The Concrete Break Test: Compressive Strength Analysis

Cube Testing: Compressive Strength of Concrete Explained

Concrete Strength Test: At Home and On-site

Strength Testing of Concrete Cores: Sampling and Procedures

Concrete Cylinder Compression Test: Evaluating Strength

Cost of a Compression Test Machine: Concrete Tests

How to Use a Concrete PSI Chart

Concrete Compression Test: Equipment Needed

Concrete Strength Testing and Steel Reinforcements

Concrete Strength Test: Fixing Failures

28 Days to Testing Concrete for Strength

Compression Strength of Concrete With The Perfect Products

Concrete Water Permeability for Durability and Performance

Decoding the Surface: Is Concrete Porous or Nonporous?

Top Concrete Strength Testing Methods: Structural Integrity

Concrete Cube Testing: An In-Depth Guide

Concrete Cube Testing: An In-Depth Look

How to Calculate Unit Weight Concrete in 2023

Determining Unit Weight of Concrete for Accurate Measurement

Concrete Strength: Unraveling the Mystery of PSI

Concrete Break Machine Models for Efficient Strength Testing

Test for Strength of Concrete: Measure and Assess Strength

The Concrete Break Test: Compressive Strength Analysis

ASTM C39: Mastering Compressive Strength Tests on Concrete