Sieve Mesh Sizes: Guide to Understanding Different Mesh

Choosing the right sieve mesh size is essential for accurate particle size separation. This article demystifies sieve mesh sizes, explaining how they’re measured, why they matter, and guides you on selecting the appropriate one for your application, with insights on practical uses in various industries.

Key Takeaways

-

Sieve mesh size indicates the number of openings in one square inch of a screen, with a higher mesh number corresponding to smaller particle capture size due to the inversely proportional relationship between mesh number and particle size.

-

Mesh sizes are standardized across different industries and uses according to international and industry-specific standards, such as ISO 3310-1 and ASTM E11, to ensure consistency and reliability in particle size separation processes.

-

Selecting the appropriate sieve mesh size is a critical decision that depends on the particle size distribution of the material, industry-specific requirements, the intended application, and can benefit from expert assistance for optimal results.

Understanding Sieve Mesh Sizes

The world around us is filled with materials of various sizes – from the fine grains of sand on a beach to the larger chunks of gravel on a hiking trail. Separating and analyzing particles for various purposes is a key process in industries like pharmaceutical manufacturing, geotechnical engineering, and food processing. The hero of this process is the sieve, a tool that uses different mesh sizes to capture and categorize particles, such as glass beads.

But what exactly are these mesh sizes? And how do they vary and contribute to the functionality of sieves? Let’s uncover these intriguing aspects.

Defining Sieve Mesh Size

The sieve mesh size is determined by counting the number of openings in one square inch of a screen. This measurement offers a straightforward way to understand the size of the sieve mesh. Think of it as a grid of tiny squares over a specific area. The more squares (or openings) we have in that area, the higher the mesh number. So, a higher mesh number means smaller particles can pass through the sieve, and a lower mesh number means larger particles can pass through.

This might seem counterintuitive at first. After all, wouldn’t a larger number of holes mean larger particles? In the world of sieves, it’s the exact opposite! This inverse relationship between mesh size and particle size is key to understanding how sieves work. Moreover, it becomes indispensable in sieving different materials where each demands a specific mesh size to effectively separate its particles.

Factors Affecting Mesh Size

Several factors come into play when it comes to sieve mesh size. For instance, the thickness of the wire used in the sieve can affect the mesh size. Thicker wires are generally used for coarser mesh sizes, while thinner wires are used for finer mesh sizes.

The factors that affect the performance of a sieve mesh include:

-

The material of the mesh

-

The mesh size

-

The aperture size

-

Manufacturing tolerances

The aperture size of a sieve mesh is another factor. Increasing the aperture mesh size increases allows larger particles to pass through, while a decrease restricts the passage of smaller particles. Manufacturing tolerances also play a role, ensuring the apertures fall within a specified tolerance range, a critical factor in preserving the intended mesh size.

The Relationship Between Mesh Size and Particle Size

The relationship between mesh size and particle size is fundamental to the functionality of sieves. This relationship is inversely proportional, meaning that as the mesh number goes up, the particle size decreases, and vice versa. This inverse relationship is critical for sieving processes as it dictates the size of particles that can be segregated from a mixture.

But, how does this inverse relationship translate in practical terms? And how does the particle size distribution impact the selection of sieve mesh size? Now, let’s uncover more about this.

Inverse Proportionality

The principle of inverse proportionality governs the relationship between sieve mesh size and particle size. In other words, as the mesh number (the number of sieve openings per square inch) increases, the size of the openings decreases. This, in turn, allows smaller particles to pass through the sieve.

From a mathematical perspective, this inverse relationship is attributed to the definition of mesh size. The higher the number of smaller openings, the smaller the size of particles that can pass through. The importance of this principle in sieving processes lies in its role in determining the size of particles that can be segregated from a mixture. Grasping this relationship becomes vital when selecting the suitable sieve mesh size for varying applications.

Particle Size Distribution

Particle size distribution has a significant impact on the selection of sieve mesh size. It determines the range of particle sizes that can pass through the sieve. Sieve analysis is used to ascertain this distribution, and the selection of different mesh sizes is based on the desired range of particle sizes to be measured.

In geotechnical engineering, for example, particle size distribution is crucial for forecasting the strength and properties of soil. By using appropriate sieve mesh sizes, engineers can gain invaluable insights into the soil’s properties, facilitating informed decision-making regarding its applications. This particle size distribution is determined by multiplying the quantity in each measurement class by the mean size measurement class, then summing the individual values.

Mesh Size Standards and Regulations

Mesh sizes aren’t arbitrary – they’re governed by various international and industry-specific standards. These standards ensure consistency and standardization of mesh sizes and mesh openings across diverse testing purposes. They also take into account the specific needs of various industries, specifying minimum requirements for opening sizes, wire diameters, and frame sizes to ensure that sieves meet the precision required for specific industry testing methods.

But what do these standards look like in practice? Let’s explore the dynamics of sieve mesh size standards and regulations.

International Standards

International standards play a significant role in regulating the use of sieve mesh sizes. They ensure that the manufacturing of test sieves adheres to specific technical requirements and testing methods. For example, the ISO 3310-1 standard specifies the technical requirements and test methods for test sieves of metal wire cloth. It covers aperture sizes ranging from 125 mm down to 20 µm, in accordance with ISO 565.

Another key international standard is the ASTM E11, which delineates specifications for standardizing sieve mesh sizes. It encompasses:

-

Woven wire sieve cloth

-

Sieve construction

-

Frame sizes

-

Nominal aperture sizes

These international standards offer a reliable framework for ensuring the accuracy and consistency of sieve mesh sizes, thus serving as a vital reference point for industries across the globe.

Industry-Specific Standards

While international standards provide a general framework, industry-specific standards fine-tune the usage of mesh sizes to meet the unique needs of different industries. For example, in the pharmaceutical manufacturing industry, the American Standard Test Sieve Series is often used. In the U.S., standard sieve sizes typically range from 3 inches to 12 inches, with opening sizes varying from 5 inches (125 mm) to 635 mesh units (20 microns), and one linear inch being a common measurement unit.

Similarly, in geotechnical engineering, the standards for the gradation testing of soils using test sieves are regulated by ASTM D6913 for soil particles as fine as 75µm (No. 200 sieve size). These industry-specific standards ensure that sieves meet the precision required for specific industry testing methods, guaranteeing the sieves’ appropriateness for specific industry testing methods.

Mesh to Micron Conversion

In the world of sieves, it’s not all about millimeters and mesh sizes. There’s another unit of measurement that’s equally important – the micron. A micron, or micrometer, is one millionth of a meter. It’s commonly used to measure the size of particles that pass through a sieve.

But how do mesh sizes translate to microns? And how can this conversion be useful for practical applications? Let’s explore the nuances of mesh to micron scale conversion.

Conversion Formula

Converting many mesh sizes to micron involves a simple mathematical formula: Mesh x Micron = 14900. This formula is suitable for conversions within the range of 50 to 400 mesh. But remember, this formula is an approximation. It’s intended for general guidance rather than precise measurement when converting between mesh sizes and microns.

Why is this approximation necessary? Due to variables such as wire width and diameter and different types of sieves, conversions cannot be standardized across all types. Therefore, the Mesh x Micron = 14900 formula should be regarded as a useful guide, rather than an exact figure.

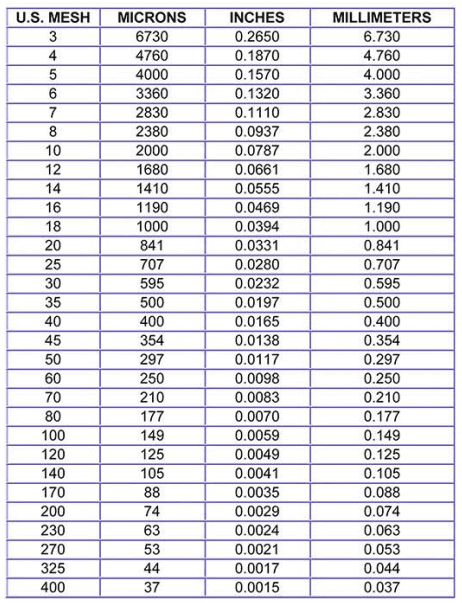

Mesh to Micron Conversion Chart

In addition to the conversion formula, a mesh to micron conversion table or chart can be an incredibly useful tool. This tabular representation illustrates the correlation between sieve mesh sizes and their corresponding micron sizes, making the conversion process a breeze, even when dealing with measurements in linear inch.

To read a conversion chart, one must comprehend the relationship between the mesh size and its corresponding micron size. This type of chart serves as a quick reference for comparison, usually displaying the mesh size on one side and the micron size on the other. Such a chart is a valuable tool for anyone regularly working with sieves and particle analysis.

Practical Applications of Sieve Mesh Sizes

Now that we’ve covered the science and mathematics behind sieve mesh sizes, let’s examine how they’re used in real-world applications. From pharmaceutical manufacturing to geotechnical engineering, sieve mesh sizes play a crucial role in diverse industries. They’re essential for separating and analyzing particles, ensuring consistent product quality, and providing valuable insights into material properties.

Now, let’s look more closely at these practical applications.

Pharmaceutical Manufacturing

In the pharmaceutical manufacturing industry, the consistency of product particle size is crucial. It affects everything from the drug’s dissolution rate to its bioavailability. This is where sieve mesh sizes come in. By determining the pore size of sieves, manufacturers can ensure the desired particle size distribution of raw materials and finished products, directly impacting drug dissolution and bioavailability.

Mesh sizes ranging from 40 to two inches 400 are commonly used in the pharmaceutical industry for shifting and milling raw materials, ensuring the attainment of the appropriate particle size for each drug’s formulation. By reducing the particle size, sieving facilitates faster and more efficient dissolution when the drug is administered, leading to improved therapeutic efficacy.

Geotechnical Engineering

In the field of geotechnical engineering, sieve mesh sizes are used to conduct soil gradation testing. This process aids in the classification of soil particles as either coarse or fine, following the ASTM D6913 guidelines. By understanding the particle size distribution of soils, engineers can assess the soil’s suitability for various construction and engineering projects.

Sieve mesh sizes are also employed in sieve analysis methods to evaluate the grain size distribution of soils. This data is crucial in understanding the engineering properties of the soil, including its permeability, compaction characteristics, and shear strength, which in turn affect the stability and design of engineering projects.

Sieve Construction and Materials

While understanding sieve mesh sizes is crucial, it’s equally important to understand the construction and materials used in sieves. After all, the durability and functionality of a sieve don’t just depend on the mesh size, but also on the materials used in its construction.

So, what materials are commonly used in sieve construction? And how do they affect the performance of a sieve? Let’s examine this aspect.

Frame Materials

The frame of a sieve is its backbone, providing stability and structure. It’s commonly made from either brass or stainless steel. Both materials have their unique advantages. Stainless steel, for instance, is known for its superior durability and reduced risk of contaminating sensitive materials during processing. On the other hand, brass, a combination of copper and zinc, is known for its high quality and long-lasting durability, despite being softer than stainless steel.

The diameter of a sieve frame is chosen based on the specific requirements of the particle analysis test and to determine the necessary size of the sieve. Commonly used diameters include 3in (76mm), 8in (203mm), and 12in (305mm). These frame sizes can accommodate a wide range of mesh sizes, making them versatile for various applications.

Wire Cloth Materials

The wire cloth is the heart of a sieve, responsible for capturing and categorizing particles. Like the frame, it can be made from various materials, including stainless steel and brass. Stainless steel wire cloths are particularly popular due to their durability and corrosion resistance. Brass wire cloths, while softer and less durable, are a cost-effective option for certain applications.

The thickness of the wire cloth material also plays a significant role in determining the mesh size. Thicker wires lead to smaller openings, which restrict the size of particles that can pass through the sieve. This characteristic makes wire cloth materials a key factor to consider when selecting a sieve mesh size.

Sieve Maintenance and Verification

Now that we’ve covered the construction and materials of sieves let’s turn our attention to their maintenance and verification. Just like any other tool, sieves need to be properly maintained to ensure their accuracy and extend their lifespan. Additionally, verifying the mesh size of a sieve is crucial to guarantee accurate particle size separation.

But how does one go about maintaining and verifying sieves? Let’s discover.

Checking Sieve Sizes

Regularly checking sieve sizes is crucial due to the distortion and abrasion that can occur with use. Distortion can be caused by sample loads, while abrasion can reduce wire diameters. Both can lead to inaccurate results, emphasizing the importance of regular sieve checks. It’s recommended to check test sieve sizes every 6 to 12 months, depending on the level of usage.

Validation options are available to ensure accurate sieve sizes. These include verification measurements to meet ASTM or ISO specifications and the use of calibration spheres to ascertain the actual results obtained by each tested sieve. By regularly checking and validating sieve sizes, you can ensure accurate and consistent particle size analysis.

Sieve Verification Services

Sieve verification services offer a comprehensive solution to ensure accuracy and traceability, as well as quality control. These services include the calibration, inspection, and certification of test sieves, providing peace of mind for users.

Verification services offer the following benefits:

-

Ensure accuracy and traceability through the certification of test sieves using precise measurement techniques

-

Provide detailed reports containing statistical data and traceability to recognized standards

-

Invaluable for industries that rely on precise and accurate particle size analysis

Selecting the Right Sieve Mesh Size for Your Needs

Now that we’ve covered the ins and outs of sieve mesh sizes, it’s time to apply this knowledge to select the right sieve mesh size for your specific needs. From considering factors like industry standards and particle size requirements to seeking expert assistance, the selection process involves multiple aspects.

Let’s examine these considerations to guide you towards an informed decision.

Factors to Consider

Choosing the right sieve mesh size involves several factors. These include established industry standards, the size of the particles to be separated, and the material to be sieved. It’s also important to consider practical factors like the size of the particles to be separated, the type of material to be sieved, and the frame type of the sieve.

The particle size has a significant impact on the selection of sieve mesh size. Different particle sizes require different sieve mesh sizes to effectively separate and analyze the particles. Understanding these factors can help you select the appropriate sieve mesh size for your specific needs.

Expert Assistance

While understanding these factors is crucial, seeking expert assistance can be invaluable in selecting the right sieve mesh size. Experts can guide you through the selection process, ensuring the appropriate sieve mesh size is chosen for your intended application. They can perform sieve analysis or gradation tests to evaluate the particle size distribution of the material and take into account the sample quantity and the approximate particle size distribution when choosing the mesh size.

Whether you need help with sieve selection or have questions about mesh sizes, don’t hesitate to seek expert assistance. Numerous services are available that offer professional assistance in sieve selection, providing you with top-notch sieving and filtration solutions to enhance efficiency and refine product quality.

Summary

From understanding the definition and factors affecting sieve mesh sizes to exploring their practical applications and maintenance, we’ve journeyed through the fascinating world of sieves and their mesh sizes. We’ve discovered the crucial role they play in various industries, learned how to convert mesh sizes to microns, and gained insights into the selection process. With this knowledge, you’re now equipped to make informed decisions about sieve mesh sizes, whether you’re working in the pharmaceutical industry, geotechnical engineering, or any field that requires precise particle size analysis.

Certified MTP has the largest selection of aggregate testing supplies, showcasing industry-leading brands for Sieve Shaker Machines, test sieves, Classification Devices for Aggregate Testing, Sample Splitters and Dividers, and Specific Gravity Test Equipment.

Frequently Asked Questions

What is mesh sieve?

A mesh sieve, also known as a sifter, is a tool made of a metal fine-mesh weave with a handle attached. It is used to aerate and separate dry ingredients, leading to a lighter and more tender crumb in baked goods.

Is it a strainer or sieve?

It’s a sieve, it is used for greater filtration and catching solids and particles with its fine mesh, unlike a colander which has larger holes. Strainers are often referred to as sieves and are used in various culinary preparations.

What is a sieve used for?

A sieve is used to strain liquids or sift dry ingredients by capturing large pieces of food and separating them from the finer substance that passes through. The size of the sieve’s mesh surface determines its separating power.

What is a sieve size?

Sieve size refers to the diameter of a test sieve, with typical sizes including 12”, 8”, 3”, 300mm, and 200mm. Sieve size analysis is important for confirming the granular profile of protective materials applied to metal surfaces for corrosion protection.

What is the process of converting mesh sizes to microns?

The process of converting mesh sizes to microns involves using the formula Mesh x Micron = 14900 for meshes within the range of 50 to 400. However, it’s important to note that this is an approximation for general guidance rather than precise measurement.

View the full line of Aggregate Testing Products and Aggregate Moisture Testing Equipment, especially the popular Aggregate/Sand Moisture Measurement System

Related Blogs for Sieve Mesh

Sieve Brushes for Efficient Cleaning and Maintenance

Top Scrub Brush for Concrete: Your Ultimate Cleaning Tool

Quality Lab Brushes for Efficient Cleaning and Maintenance

Retsch AS200 Sieve Shaker: Mastering Particle Size Analysis

ASTM C136: Guide to Fine and Coarse Aggregate Sieve Analysis

Sand Sieve Size: A Guide for Optimal Sifting

Sieves for Soil: Finding the Perfect Match for Gardening

Sieve Analysis of Soil: A Guide to Particle Size Assessment

Understanding Aggregate Sieve Sizes: A Comprehensive Guide

ASTM Sieve Sizes: A Complete Sizing Chart Breakdown

Graph for Sieve Analysis: A Guide to Accurate Soil Grading

Sieve Test: A Guide to Particle Size Analysis

Top-Quality Sieves for Precise Material Separation

Sieve Shaker Selection: Find the Model for Material Analysis

Sieve Size Chart: Understanding Mesh and Particle Sizes

Sieve Essentials: Understanding Its Functions & Applications

The Ultimate Sieve for Compost Mastery: Simplify Your Soil

Sieve Shaker for Sale: Find the Perfect Fit for Your Lab

Sifting with Gilson Sieves: Your Guide to Material Analysis

Gilson Sieve Shaker: Particle Size Analysis

Top Standard Test Sieves for Accurate Material Analysis

Using Retsch Lab Sieves and Sieve Shakers for Analysis

What is a Shaker Sieve and Particle Sizing Analysis

Understanding ASTM D 422: Sieve Analysis and Particle Size

Sizes of Sieves: A Comprehensive Guide

Sieve Analysis: A Guide to Grain Size Distribution

Understanding Sieves: A Comprehensive Guide to Test Sieves