Understanding Rolling Thin Film Oven Testing Equipment

Have you ever wondered how engineers predict the durability and performance of asphalt pavements? The answer lies in a crucial testing method known as Rolling Thin Film Oven (RTFO) testing. This test provides valuable insights into the behavior of asphalt binders, which are the glue that holds our roads together. By understanding the effects of heat and air on these binders, engineers can make informed decisions when designing and constructing pavements that are built to last.

In this blog post, we will delve into the world of RTFO testing, exploring its importance, test methods, equipment, factors influencing asphalt binder aging, and its applications and limitations. By the end, you will have a comprehensive understanding of this essential testing technique and its role in predicting the performance of asphalt pavements.

Key Takeaways

-

Rolling Thin Film Oven (RTFO) testing is used to evaluate the effects of heat and air on asphalt binders for pavement design.

-

Parameters measured include mass change, volatility, and condition of asphalt when placed in the pavement.

-

Rolling thin film oven test simulates short-term aging but must be combined with complementary tests such as Pressure Aging Vessel (PAV) to provide comprehensive insight into asphalt binder properties.

The Importance of Rolling Thin Film Oven Testing

Asphalt binder plays a critical role in the performance of pavements, as it binds the aggregates together and provides resistance to various forms of distress, such as cracking and rutting. Understanding the binder’s behavior under varying weather conditions, is key to ensuring pavement longevity. This is where Rolling Thin Film Oven (RTFO) testing comes into play. Rolling Thin Film Oven testing simulates the short-term aging process that occurs during the production and placement of a hot mix asphalt binder, allowing engineers to predict pavement behavior and potential distresses, much like a moving film that unfolds the story of the pavement’s life.

The primary purpose of Rolling Thin Film Oven testing is to evaluate the effects of heat and air on asphalt binders, including asphalt binder modifiers. Replicating the aging process during production and paving operations provides engineers with insights into asphalt binder modifiers’ performance and durability, facilitating the design and maintenance of durable pavements.

Asphalt Binder Aging

Asphalt binder aging is a natural process that occurs over time, mainly due to the loss of volatile components. This loss results in an increase in the binder’s viscosity, which can affect pavement performance. The RTFO test equipment, such as air pressure gauge range, ensures accurate results during the testing process.

Aging of asphalt binder can be attributed to various factors, including volatilization, oxidation, and polymerization. These processes lead to changes in the binder’s properties over time, impacting its performance in pavements. With proper testing equipment, such as double exhaust vents and temperature display, RTFO testing can accurately measure the effects of aging on asphalt binders.

Predicting Pavement Behavior and Distress

RTFO testing is an essential tool for predicting pavement behavior and potential distresses. Simulating the short-term aging process of asphalt binders offers engineers valuable insights into the performance and durability of pavement under conditions like fatigue cracking, rutting, and low-temperature cracking.

One of the key benefits of Rolling Thin Film Oven testing is its ability to provide important information on the long-term aging characteristics of asphalt binders. Exposing the binder to high temperatures and air flow in the RTFO test aids engineers in predicting pavement behavior and potential distresses such as cracking, rutting, and stripping. The test’s accuracy is crucial for understanding the binder’s performance and ensuring that our roads are built to last.

The Rolling Thin Film Oven Test Method

The RTFO test method is a standardized testing procedure that involves heating a thin film of asphalt binder in an oven while rotating it. The primary goal of this test is to measure changes in the binder’s mass and other characteristics, providing valuable insights into the effects of heat and air on the material.

The test method is widely used in the asphalt industry, following standardized guidelines such as AASHTO T 240 and ASTM D 2872. These guidelines ensure that the testing process is consistent and reliable, providing accurate results that can be used to inform pavement design and construction decisions.

Test Procedure

The RTFO test procedure adheres to standard guidelines, including AASHTO T 240 and ASTM D 2872, ensuring that the process is consistent and reliable. The EN 12607-1 test requires heating the asphalt binder at elevated temperature of 163 °C (325 °F) for 75 minutes. Alternatively, ASTM D2872 and AASHTO T240 require 85 minutes of heating.

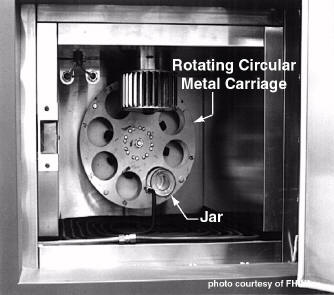

During the test, unaged asphalt binder samples are placed in cylindrical glass bottles and positioned in a rotating carriage within an oven. The carriage rotates while the samples are aged at the same specified test temperature and oven temperature, simulating the aging process that occurs during asphalt production and placement.

The RTFO test procedure provides valuable insights into the effects of heat and air on the asphalt binder, helping engineers make informed decisions about pavement design and construction.

Parameters Measured

One of the many factors the primary parameters measured during RTFO testing is the mass change of the asphalt binder sample, expressed as a percentage of the initial mass. This measurement is crucial for simulating short-term asphalt binder aging and assessing the impacts of aging on the binder’s characteristics.

The mass change primarily reflects the loss of volatiles in the asphalt binder during the aging process. Measuring this parameter allows engineers to understand the volatility of the binder and the potential for ‘blue smoke’ during asphalt production. Additionally, this information helps predict the condition of the asphalt when placed in the pavement, ensuring that our roads are built to withstand the test of time.

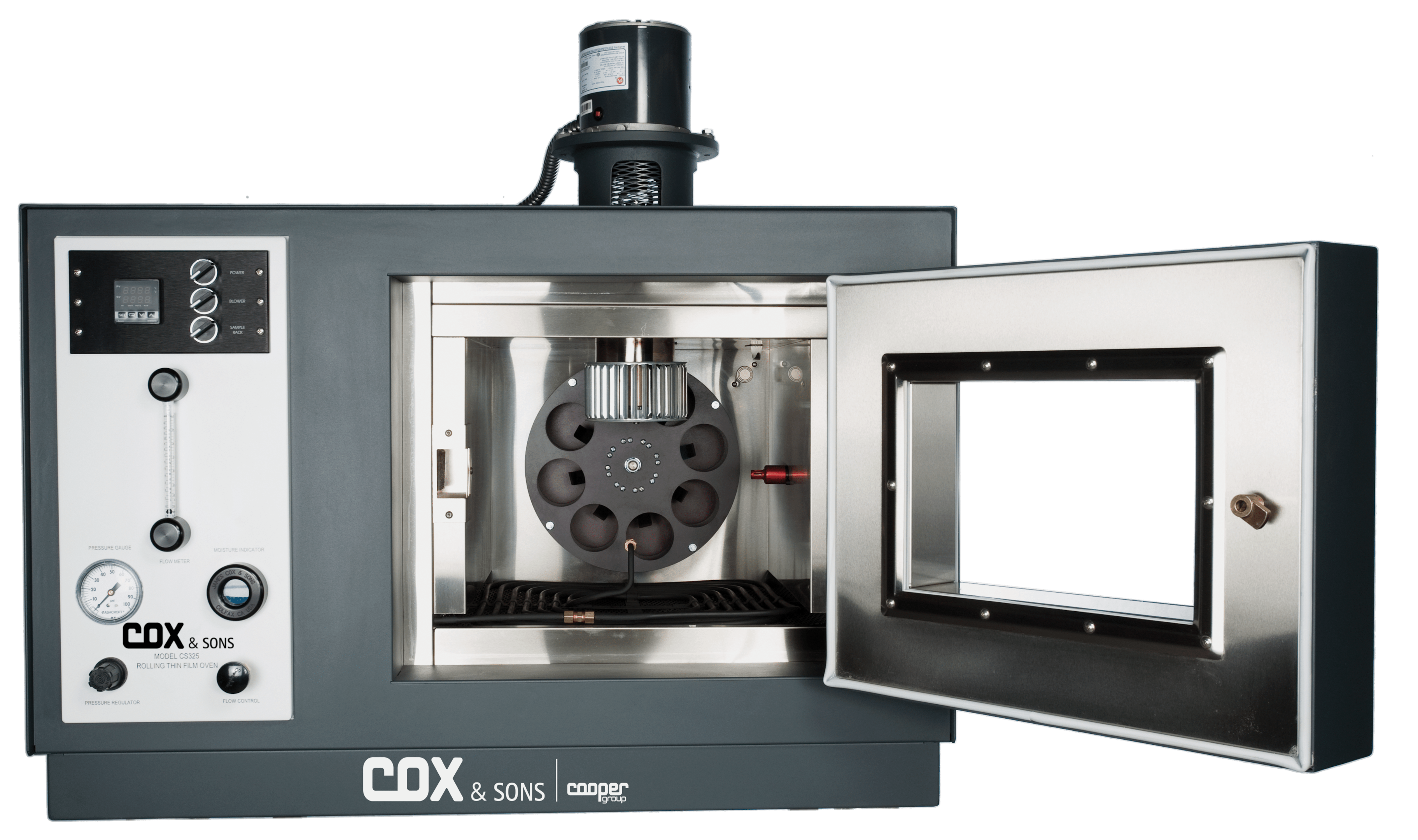

Equipment and Tools for RTFO Testing

High-quality equipment and tools are essential for accurate RTFO testing results. The testing equipment includes:

-

An RTFO unit

-

Specimen molds

These tools ensure that the test procedure is carried out consistently and reliably, providing valuable information about the aging process of asphalt binders.

In addition to the equipment, proper maintenance of the RTFO oven is crucial for consistent and accurate test results. This includes:

-

Cleaning

-

Inspection

-

Calibration

-

Lubrication

-

Record keeping

Maintaining the testing equipment in good working condition ensures trustworthy RTFO testing results, which in turn inform pavement design and construction decisions.

Thin Film Oven Features

Thin film ovens used in RTFO testing have several unique features that ensure accurate and reliable results. These features include a uniquely and specially designed oven, carousel for loading samples, precise temperature control, and double-wall construction for maintaining the measured temperature.

The carousel serves to expose new asphalt binder to the heat and air flow while slowly mixing each sample, simulating the aging process that occurs during fresh asphalt binder production and placement. Precise test temperature control is essential for obtaining accurate and repeatable results, ensuring that the test temperatures are maintained within the control failure temperature range of ±0.1°C and providing uniformity and consistency in the testing process.

Sample Preparation and Handling

Proper sample preparation and handling techniques are crucial for accurate RTFO testing results. This includes:

-

Refining the existing procedure

-

Explicitly detailing the requirements for sample preparation

-

Conditioning the asphalt specimens properly

-

Accurately identifying and handling the samples throughout the testing process

These field tests are integral components to ensure accurate results in RTFO testing.

Unaged asphalt binder samples are placed in cylindrical glass bottles as part of sample preparation. The samples and glass containers are then positioned in a rotating carriage and placed within an oven, as per the given test procedure. Adhering to these guidelines and employing proper sample handling techniques ensures the accuracy and reliability of RTFO testing results, thereby informing pavement design and construction decisions.

Factors Influencing Asphalt Binder Aging

Asphalt binder aging is influenced by several factors, including environmental conditions, oxidative hardening, and binder modifiers such as polymers and rubber. Understanding these factors is crucial for predicting the performance and durability of asphalt pavements.

Taking into account the multitude of factors that influence asphalt binder aging allows engineers to make informed decisions regarding the design and construction of long-lasting pavements. In the following sections, we will delve into the specific factors that influence asphalt binder aging and how they can impact pavement performance.

Environmental Conditions

Environmental factors that play a significant role in the aging of asphalt binders include:

-

Temperature fluctuations

-

Light intensity

-

Oxygen pressure

-

Freeze/thaw cycles

-

Water saturation

These factors can have a substantial influence on the durability of asphalt pavement, including its surface skin.

Light intensity, especially UV light, can also accelerate the aging process of asphalt binders, leading to decreased performance and service life. Oxygen pressure from heated air contributes to the oxidation of the binder, increasing its stiffness and making the surface skin the pavement mixture more brittle and prone to fatigue and cracking.

Understanding the impact of environmental conditions on asphalt binder aging enables engineers to design pavements better equipped to withstand these challenges.

Oxidative Hardening

Oxidative hardening is a process that occurs when oxygen diffuses into the binder, leading to an increase in the concentration of polar functional groups in the binder. This results in approximate change in the immobilization of molecules and a change in the rheological properties of the binder.

The effects of oxidative hardening on asphalt binder aging can lead to various forms of pavement failures, such as cracking and disintegration. Understanding the impact of oxidative hardening on asphalt binder aging aids engineers in predicting pavement performance and designing pavements more resistant to these types of failures.

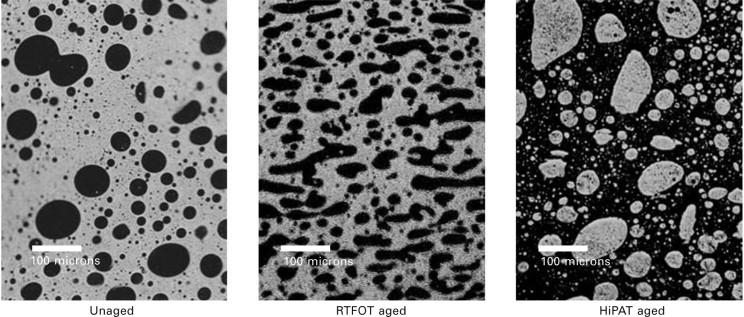

Binder Modifiers

Binder modifiers, such as polymer modified bitumens (PMBs) and rubberized asphalt, can impact the aging behavior of asphalt binders. These modifiers can improve the binder’s resistance to oxidation and other aging processes, enhancing its durability and performance.

Incorporating binder modifiers into hot mix asphalt binder mixtures helps maintain the hot mix asphalt and binder’s desired properties over time, mitigating the effects of aging and enhancing pavement durability. Understanding the role of binder modifiers in asphalt binder aging is crucial for designing and constructing durable construction and pavements that perform well under various conditions.

Applications and Limitations of RTFO Testing

RTFO testing is widely used for simulating short-term aging and field performance of asphalt binders, providing valuable information on their performance and characteristics under simulated aging conditions. However, the test method also has limitations, such as potential inaccuracies in representing field aging and the inability to replicate long-term aging. To overcome these limitations, additional tests, such as the Pressure Aging Vessel (PAV) test, can be used in conjunction with RTFO testing to provide a more comprehensive understanding of pavement behavior.

In the following sections, we will discuss the applications of RTFO testing in more detail, as well as its limitations and the complementary tests that can be employed to provide a complete picture of asphalt binder performance.

Short-term Aging Simulation

RTFO testing is a commonly used method for simulating the short-term aging of asphalt binders, which occurs during the production and placement of asphalt mixtures. Subjecting the binder to high temperatures and air flow replicates the field aging process, offering valuable insights into the binder’s performance and durability.

Engineers rely on RTFO testing to evaluate the performance of asphalt binders under various conditions, such as fatigue cracking, rutting, and low-temperature cracking. Accurate short-term aging simulation through RTFO testing is crucial for understanding the binder’s performance and ensuring that our roads are built to withstand the test of time.

Limitations and Complementary Tests

While RTFO testing is valuable for simulating short-term aging, it has limitations in accurately representing significant aging and long-term aging effects on pavement behavior. To accomplish simulated significant aging more effectively, complementary tests like the Pressure Aging Vessel (PAV) test can be used to address these limitations alongside RTFO testing.

The PAV test simulates long-term aging of asphalt binders by subjecting them to high temperatures and pressures for an extended period. When combined with RTFO testing, these two tests provide a comprehensive assessment of the binder’s properties under various aging conditions, ultimately informing pavement design and construction decisions.

Summary

In conclusion, Rolling Thin Film Oven (RTFO) testing is a crucial tool for understanding the effects of heat and air on asphalt binders, helping engineers predict pavement behavior and potential distresses. By simulating short-term aging, RTFO testing provides valuable insights into the performance and durability of asphalt pavements under various conditions.

While RTFO testing has its limitations, the use of complementary tests such as the Pressure Aging Vessel (PAV) test can provide a more comprehensive understanding of pavement behavior. By considering the various factors that influence asphalt binder aging, engineers can design and construct pavements that perform well under a wide range of conditions, ensuring the longevity and safety of our roads.

Certified MTP has an elite selection of asphalt testing equipment and supplies such as Asphalt Binder Testing, Mix Marshall Design tools and equipment, as well as showcasing industry-leading brands for Mashall Stability Test Systems, Marshall Compactor Test Equipment and Molds, Marshall Water Baths for Asphalt Testing, and Sample Ejectors for Asphalt Extrusion.

Frequently Asked Questions

What is the use of rolling thin film oven?

The Rolling Thin Film Oven (RTFO) Test is used to measure the effect of heat and air on asphalt binder, simulating short-term aging that occurs during production and paving operations. This helps to investigate and predict early age HMA pavement behavior and distress.

What is the thin film oven test of bitumen?

The Thin Film Oven test simulates the effects of heat and air on asphalt binder by heating a film of it in an oven for 5 hours at 163° C (325°F). The physical properties of the asphalt binder are measured before and after the oven treatment.

What is the difference between TFOT and RTfot?

The TFOT involves heating asphalt binder samples in an oven for a prolonged period, while the RTFO is a more advanced test which offers an improved version of simulated aging.

What does Rtfo stand for?

Rtfo stands for Renewable transport fuels obligation, an obligation which requires fuel suppliers to include a certain percentage of biofuels in their sales.

What parameters are measured during RTFO testing?

RTFO testing measures the mass change of the asphalt binder sample, which indicates the gain weight loss of volatiles and is expressed as a percentage of the initial mass.