Understanding ASTM C109 is essential for construction professionals and testing labs as it determines the compressive strength of hydraulic cement mortars—a key indicator of material performance in structural applications. Our article dissects the testing method, offering detailed insights into the preparation, execution, and analysis of ASTM C109, equipping you with the necessary tools to ensure your mortars meet industry standards.

Key Takeaways

- ASTM C109 is an essential standard for testing the compressive strength of hydraulic cement mortars, requiring 2-inch cubes and specific curing conditions for accurate and reliable results.

- Proper specimen preparation and testing procedures—including accurate dimensions, curing environments, and load accuracy—are critical for the validity of ASTM C109 test results.

- Compliance with ASTM C109 involves careful data analysis and adherence to specific guidelines; discrepancies should be within permissible variability limits, and non-compliant results necessitate a review of procedures and standards.

Exploring the Purpose of ASTM C109

The ASTM C109 is a vital standard testing methodology in the construction industry. Its primary function is to determine the compressive strength of hydraulic cement and other mortars. But why is this so important?

The answer lies in the fact that it provides a direct measure of a material’s ability to withstand loads without failure. This knowledge is vital in confirming that the concrete used in structures meets the required strength specifications, subsequently guaranteeing the structural integrity and safety of our buildings.

Keep Reading: ASTM C 143 Slump Test: Mastering Concrete Consistency.

But how exactly is the ASTM C109 employed in the testing of cement mortars? The process involves the use of 2-inch cubes of hydraulic cement mortars. The materials used to make these cubes typically include graded standard sand, cement, and water. Subjecting these cubes to compressive strength testing allows us to gauge the material’s resilience against loads without failure. Considering any regulatory limitations before conducting the test is crucial for compliance with local and international standards.

Specimen Preparation Guidelines

Preparation for the ASTM C109 test demands careful attention to detail, especially while preparing your specimens. The dimensions and form of a specimen can significantly impact the compressive strength and modulus of elasticity of the specimens. The prescribed dimensions for the test cubes are 2 inches or 50 mm.

Additionally, the curing conditions, including temperature and humidity, play a substantial role in determining the accuracy of the results. Let’s delve deeper into these aspects to understand their significance.

Size and Shape of Test Cubes

In the world of ASTM C109 testing, size does matter. The test cubes utilized in the test have measurements of 2 inches or 50 mm on each side. Adhering to these prescribed dimensions is crucial for accurate and dependable test results. The test results have indicated that the compressive strength of the mortar is significantly influenced by the specimen size and water content. Therefore, any deviation from the prescribed size could lead to unreliable test results.

But why a cube shape? The cube shape is favored due to its ability to yield consistent and reliable results in cement testing. While other shapes may be used in some cases, it’s important to note that they may not provide exact equivalents in terms of compressive strength and modulus of elasticity. Therefore, adherence to the cube shape is paramount to ensure consistency and reliability in your test outcomes.

Curing Conditions

Now, let’s consider the curing conditions. The prescribed curing conditions for ASTM C109 specimens involve curing them in saturated lime water. But why is this so crucial? Proper curing significantly contributes to the overall quality and strength development of cement-based products, which is vital for precise testing results.

The outcomes of ASTM C109 testing are significantly influenced by curing conditions. Research has shown that specimens cured in lime-saturated water achieve higher strength compared to those cured in fresh water. Therefore, adherence to the standard’s curing requirements is crucial for obtaining dependable test results.

However, achieving these ideal curing conditions requires specific equipment. It is recommended to use humidity curing chambers to achieve the optimal temperature and humidity conditions required for the curing of ASTM C109 specimens. Failure to adhere to proper curing conditions may result in reduced tested strength, heightened shrinkage, and the formation of cracks in the test specimens, all of which render the results of the ASTM C109 test invalid.

More Reading: ASTM C136: Guide to Fine and Coarse Aggregate Sieve Analysis.

Step-by-Step Testing Procedure Overview

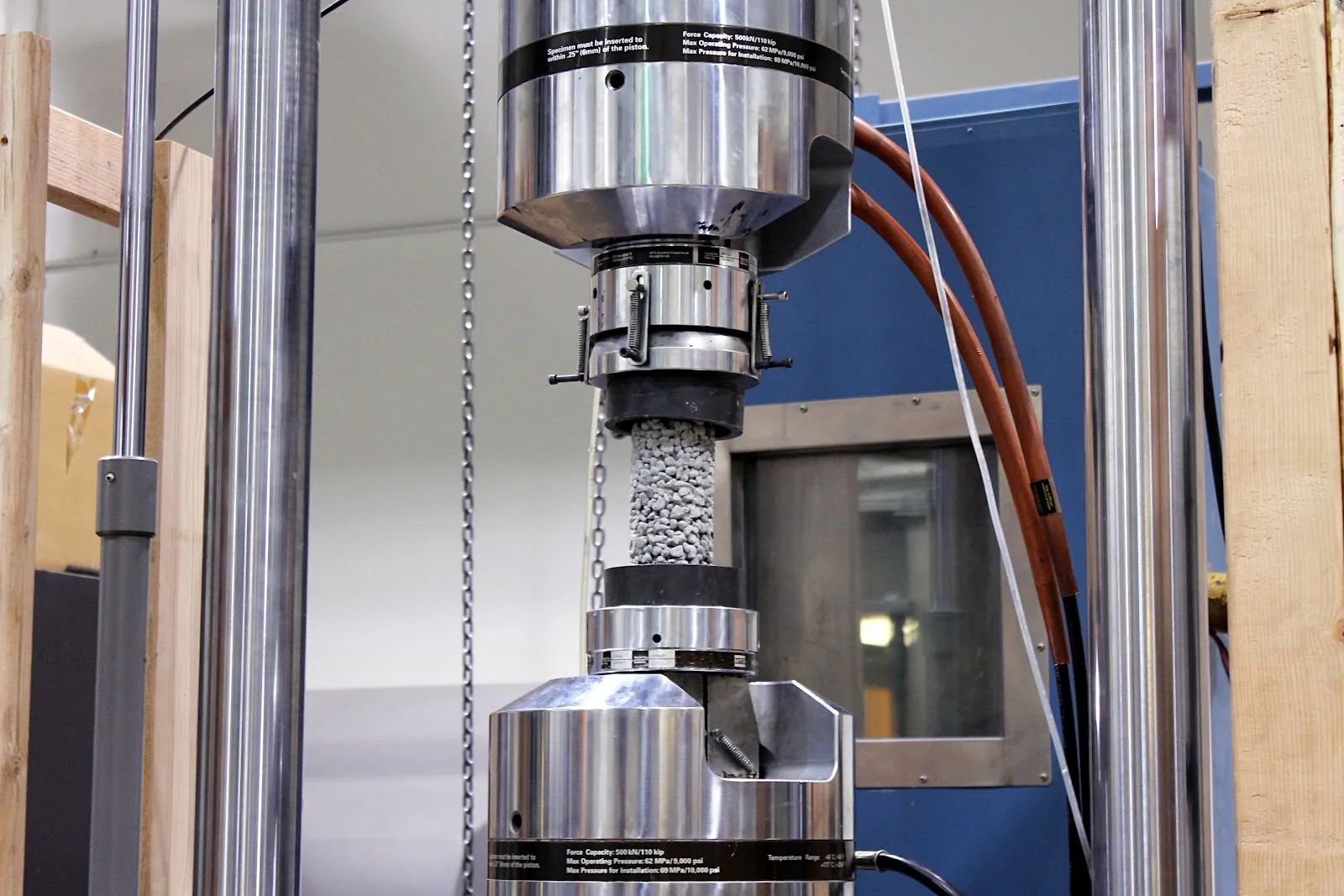

With the specimens prepared and cured, we can now proceed to the actual testing procedure. The ASTM C109 test involves setting up the compression machine and executing the test. Understanding the steps involved in this process is essential, as it forms the backbone of the ASTM C109 standard. Let’s break it down step by step.

Preparing the Compression Machine

Before we can start testing, we need to set up our compression machine. This machine plays a pivotal role in the ASTM C109 test as it is responsible for determining the compressive strength of hydraulic cement and other mortars. The setup involves placing the cement sample on the lower platen of the machine and then jogging the upper platen as far down as possible.

But as with any scientific process, there’s room for error. Some typical errors to avoid when preparing the compression machine include:

- using the wrong sampling, casting molds, or curing conditions

- inadequate compaction

- improper mixing

- insufficient curing time

- inaccurate measurement of materials

- failure to remove air voids

- failure to properly label specimens

- not adhering to ASTM C109 guidelines

By being aware of these potential pitfalls, including regulatory limitations prior, you can ensure a more accurate and reliable test outcome through an appropriate conversion of the alternative procedure.

Executing the Test

With our compression machine set up and ready to go, it’s time to execute the test. The ASTM C109 test is a method used to determine the compressive strength of hydraulic cement mortars. It is conducted using 2-inch or 50-mm cube specimens. Following the specific procedures outlined in the ASTM C109 standard is imperative for accurate results.

However, conducting the ASTM C109 test is not without its challenges. Common errors that can occur during the test include incorrect sampling and improper use of 2” cube molds. To avoid these pitfalls and ensure a successful test, it’s recommended to conduct the tests simultaneously on two specimens from the same batch of cement paste.

Adherence to these guidelines, including the implementation of acceptance tests, ensures the reliability and accuracy of your test results.

You May Also Read ASTM C39: Mastering Compressive Strength Tests on Concrete.

Selecting the Right Equipment for ASTM C109

The success of the ASTM C109 test largely depends on the use of appropriate equipment. From the compression machine to the real-time monitoring software, every piece of equipment plays a crucial role in the testing process. But how can one confirm the use of the right equipment?

Let’s explore the importance of load accuracy and real-time monitoring software in achieving accurate and reliable test results.

Importance of Load Accuracy

Load accuracy is one of the most critical factors in the ASTM C109 test. Load accuracy pertains to the precision and accuracy of the load applied during the compressive strength test of hydraulic cement mortars. A high level of load accuracy is crucial to obtaining dependable and uniform test results.

According to ASTM C109, the specified load accuracy requirement is that the load applied to the test specimen should be indicated with an accuracy of ±1.0%. Inaccuracies in the applied load can lead to an uneven distribution of force on the specimen, resulting in unreliable test results. Therefore, it’s crucial to maintain high load accuracy to ensure accurate and valid outcomes.

Real-Time Monitoring Software

In today’s digital age, the use of real-time monitoring software is becoming increasingly prevalent in various industries, including construction. This software plays a significant role in ASTM C109 testing, enabling the monitoring of properties such as:

- set time

- hydration

- hardening behavior

- stiffness

- strength of concrete

This software enhances the tracking and analysis of data by providing immediate data acquisition during the test process and displaying measurements in graphical formats for easier interpretation. Notable real-time monitoring software solutions for ASTM C109 testing include the Data Manager PC software by Controls Group and the HİRATEST H-GUI software for the Automatic Cement Compression and Flexure Testing Machine. By leveraging these software solutions, you can ensure a more effective and efficient testing process.

Health and Safety Considerations

Although the primary focus of ASTM C109 testing is to determine the compressive strength of hydraulic cement mortars, the health and safety aspects of the testing process are equally vital. This encompasses understanding the potential health risks associated with the test materials and the measures taken to keep health practices and maintain environmental control during testing.

Let’s take a closer look at these two systems of consideration, particularly when it comes to combining values and numerous other specifications.

Handling Chemicals and Materials

ASTM C109 testing involves the use of fresh hydraulic cementitious mixtures, which possess caustic properties. These materials have the potential to cause chemical burns to the skin and tissue with prolonged exposure. Therefore, it’s vital to handle these materials safely and responsibly.

Reducing the risks of chemical burns and addressing safety concerns necessitates:

- The use of suitable personal protective equipment (PPE), like gloves and protective eyewear

- Adherence to safe handling protocols

- Disposing of the chemicals and materials responsibly after the completion of testing, per local environmental regulations and the instructions provided in the material safety data sheet (MSDS).

Environmental Control

Maintaining appropriate environmental control during testing is equally important to ensure accurate results. The recommended temperature for curing test cubes is 23°C ±2°C, and it’s advised to maintain the relative humidity above 95%. These conditions are crucial for obtaining accurate and reliable results.

To achieve these ideal conditions, it’s recommended to use a humidity cabinet. Failing to maintain these conditions can lead to inaccurate results, including reduced tested strength, heightened shrinkage, and the formation of cracks in the test specimens. Therefore, maintaining proper environmental control is vital to validate the test outcomes.

Understanding Test Results and Compliance

Upon completion of the testing process, the next step is to interpret the test results and determine compliance with specifications. This involves reading and analyzing the data obtained from the test and relating these results to specifications to ensure compliance with industry standards.

How exactly is this done? Let’s delve deeper.

Reading and Analyzing Data

Reading and analyzing the data obtained from the ASTM C109 test involves considering various factors such as:

- The compressive strength of the mortar

- The curing conditions

- The age of the specimens

- The testing equipment used

High strength data indicates that the hydraulic cement mortar has a higher compressive strength, while low strength data indicates a lower compressive strength.

However, analyzing this data is not always straightforward. Discrepancies in ASTM C109 test results should be interpreted within the variability limits of other units of compressive strength, which are approximately 9.5% for three cubes and 8.4%. It’s important to consider such variations when analyzing data consistency.

The compressive strength from ASTM C109 data is determined by measuring the force applied by the compression tester and dividing it by the cross-sectional area of the mortar cube.

Relating Results to Specifications

Relating the test results to specifications is a crucial step in ensuring compliance with industry standards. The outcomes of ASTM C109 tests can be utilized to evaluate adherence to product specifications. Hence, meticulous interpretation of the results is necessary, taking into account all specified requirements and procedures to assure their reliability.

Aligning your test results with the standard test method of ASTM C109 requires meticulous adherence to all the specific requirements and procedures outlined in the standard. This test method covers the determination of various aspects, and promptly addressing any deviation from the specified test methods is important for maintaining adherence to the standards.

In the event of non-compliant ASTM C109 test results, it’s advisable to:

- Review the specifications

- Examine potential errors in testing procedures and conditions

- Refer to pertinent standards to determine the steps necessary for the mortar to meet the mandated standards.

ASTM C109 in Context: Comparisons and Related Standards

Understanding the comparative value of ASTM C109 with other mortar tests and related international standards is useful for fully appreciating its significance. By doing so, we can recognize its place in the broader industry and appreciate its global relevance.

Let’s take a closer look.

ASTM C109 vs Other Mortar Tests

ASTM C109 is not the only mortar test utilized in the construction industry. Other standard mortar tests include C780 and the ASTM standards C270. However, where ASTM C109 distinguishes itself is in its specific focus on assessing the compressive strength of hydraulic cement mortars using 2-inch cube specimens. This makes it a valuable tool in ensuring the strength and integrity of mortar in construction projects.

While ASTM C109 and international standard EN 196-1 share similarities in their purpose of assessing the compressive strength of cement-based materials, ASTM C109 specifically focuses on hydraulic cement mortar cubes and failure testing, while EN 196-1 is primarily used to ensure conformity with cement specifications and for validation testing.

Similarly, while ASTM C109, ASTM C348, and Capping Methods all serve to test the strength of cement, they differ in their specific focus, making each test unique in its application.

International Standard Equivalents

While the ASTM C109 standard is widely used in the United States, it’s important to note its global relevance. The international standard equivalent to ASTM C109 is ISO 679:2009. Other international equivalents encompass various standards that assess the compressive strength of hydraulic cement mortars, such as British standards BS EN 1015 and BS 4551, Australian standard AS 2701, and European standard EN 934 series for admixtures for concrete, mortar, and grout.

The adoption of ASTM C109 on a global scale is a testament to its practicality and significance. It has significantly influenced the standardization of testing the compressive strength of hydraulic cement mortars in laboratories across the globe, establishing itself as a widely recognized element of global cement testing standards. This not only reaffirms the importance of ASTM C109 but also facilitates international collaboration and standardization within the construction sector.

Summary

We have journeyed through the intricacies of ASTM C109, delving into its purpose, significance, and application in the testing of hydraulic cement mortars. We’ve explored the meticulous preparation guidelines for test cubes, the detailed testing procedure, the considerations in selecting the right equipment, and the critical health and safety considerations.

We’ve also understood how to interpret test results and ensure compliance with industry standards and how ASTM C109 compares with other mortar tests and international standards. As we have seen, ASTM C109 plays a pivotal role in ensuring the quality, safety, and durability of our constructions. It is a testament to the power of scientific rigor and standardization in advancing our built environment.

You can visit CertifiedMTp.com

Frequently Asked Questions

What is the ASTM C109 standard?

The ASTM C109 standard is a compression test used to determine the compressive strength of hydraulic cement and other mortars. It is an important method for compressive strength as referenced by various specifications and test methods.

What is the ASTM standard for cube testing?

The ASTM standard for cube testing is ASTM C109. It is used to determine the compressive strength of concrete by testing hydraulic cement mortar cubes to failure. The standard also specifies the equipment and procedures for creating, molding, and preparing the specimens before testing.

What size sample for ASTM C109?

For ASTM C109, the sample size should be 50mm x 50mm x 50mm. Then, follow the instructions of the cement manufacturer and cure the specimens at room temperature and at not less than 50% humidity for 20 to 72 hours.

What is the standard cement compressive strength test?

The standard cement compressive strength test involves subjecting a 50 mm cement mortar test specimen to a compressive load using a hydraulic machine until failure, with a loading sequence lasting between 20 and 80 seconds.

What is the purpose of ASTM C109?

The purpose of ASTM C109 is to determine the compressive strength of hydraulic cement and other mortars used in the construction industry.