Seeking the best thermometer infrared with precise readings can be daunting, given the abundance of choices. This article simplifies your decision by highlighting critical features to look for and how they apply to different scenarios. Dive in to discover the best infrared thermometers that strike the perfect balance between functionality and accuracy for your tasks.

Key Takeaways

- Infrared thermometers measure temperature without direct contact, making them suitable for a variety of applications, including medical, cooking, and industrial settings, and offer quick readings with features like adjustable emissivity and distance-to-spot ratios enhancing accuracy.

- Despite common misconceptions, best thermometer infrared only measures surface temperature and require proper usage techniques and regular calibration for accurate readings; factors such as emissivity values and external conditions can significantly affect their precision.

- Different types of thermometers serve specific purposes; while infrared thermometers provide non-contact surface temperature measurements, contact and probe thermometers are better for situations requiring internal temperature measurements with higher accuracy.

Understanding Best Thermometer Infrared

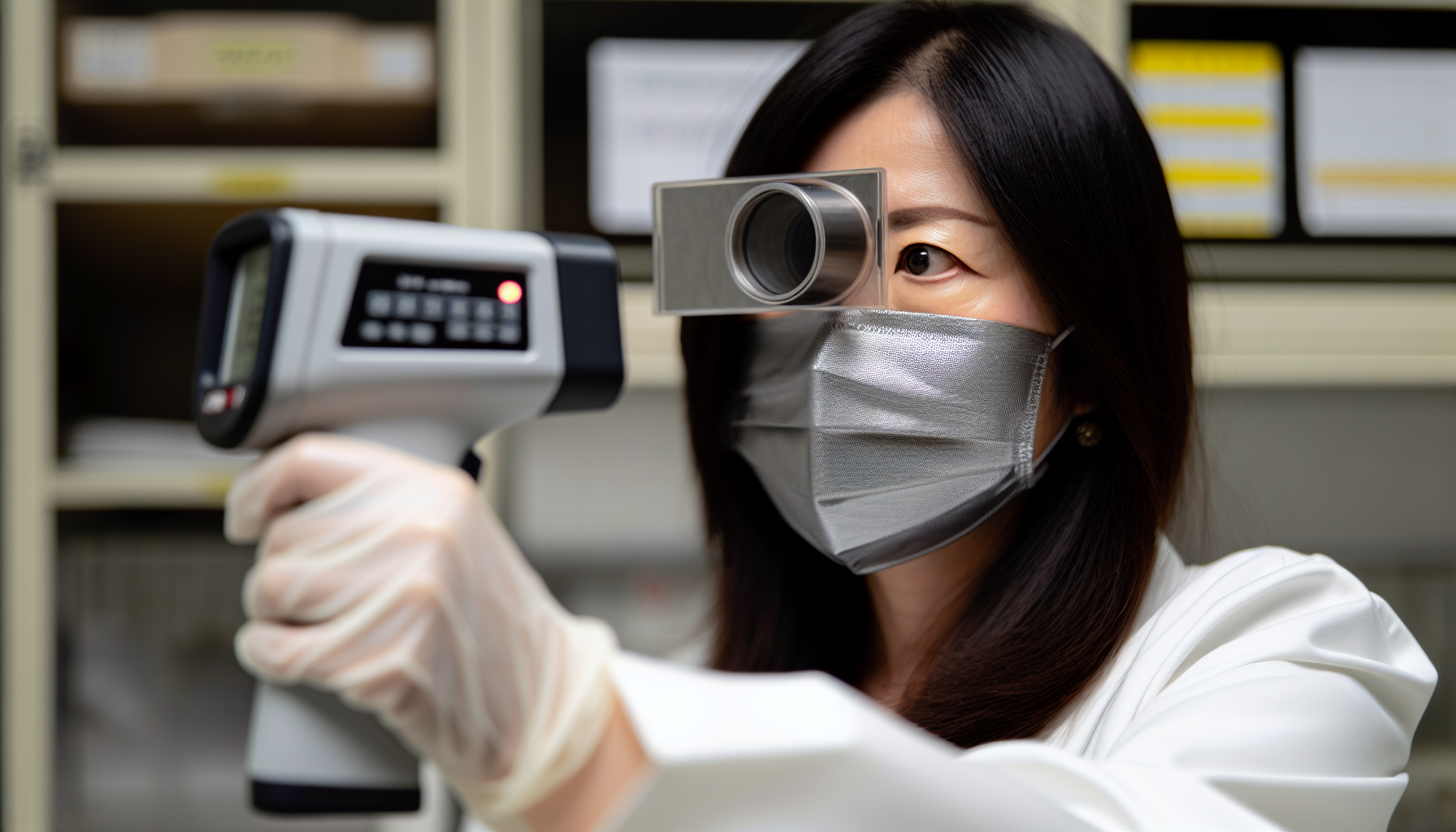

Best thermometer infrared operate on the principle of infrared radiation to measure the surface temperature of objects without direct contact. These devices capture and direct the infrared rays emitted by the object onto a detector for temperature determination. The benefits of utilizing the best infrared thermometers come from their non-contact measurement capability, enabling rapid temperature readings without the necessity of physical contact with the surface being measured.

You should consider certain features when purchasing an Infrared Thermometer, including:

- Accuracy

- Temperature range

- Adjustable emissivity settings

- Distance-to-spot ratio

This will ensure that the thermometer meets your child’s temperature specific requirements.

How Infrared Thermometers Work

Infrared thermometers function by utilizing a lens system to concentrate the infrared radiation emitted from a surface onto a detector. This infrared light emitted from all surfaces with a temperature above 0 K, and the intensity of the emitted radiation is influenced by the surface temperature, with higher temperatures leading to increased radiant energy. The key components involved in the operation of an infrared thermometer encompass a lens that focuses the infrared light emitted from the object and a detector, such as a thermopile, which converts the infrared radiation into an electrical signal.

An infrared thermometer processes temperature readings by:

- Directing the object’s emitted infrared light onto a thermopile detector.

- The thermopile converts the infrared radiation into heat.

- The heat is then transformed into electricity.

- The electricity is evaluated as a temperature reading.

Advantages of Infrared Thermometers

Best infrared thermometers classify as non-contact devices because they can measure temperature without requiring physical contact with the object or person being measured. This feature offers a significant advantage, enabling temperature measurement from a distance, making it a device suitable for scenarios where direct contact is not feasible or preferred.

In addition to their non-contact nature, infrared thermometers have a rapid response time, often providing a temperature reading in a fraction of a second. This swift performance enhances their effectiveness in high-volume applications and situations where real-time data is essential. Moreover, their versatility is demonstrated through their capability to store data, deliver rapid and precise temperature readings, and measure temperatures of moving or hard-to-access objects. Their utility spans across diverse applications such as process monitoring, plant maintenance, electrical, HVAC, and automotive maintenance.

Key Features to Consider

It’s vital to keep in mind the features that guarantee accurate and reliable readings when selecting an infrared thermometer. The accuracy of infrared thermometers plays a critical role in their performance. Factors such as the distance-to-spot ratio, emissivity settings, and the thermometer’s temperature range are important contributors to the precision of temperature measurements.

Emissivity is a significant feature as it quantifies an object’s capacity to emit infrared energy, which is crucial for determining its actual temperature itself. Maintaining correct emissivity settings in an infrared thermometer is integral to achieving accurate temperature readings. Additionally, the temperature range of the thermometer should suit your needs. Domestic infrared thermometers generally have a temperature measuring range of -50°C to 500°C, while industrial infrared thermometers typically offer a broader range to accommodate the diverse extreme temperature measurements in industrial environments.

Best Thermometer Infrared for Industrial Use

For those in an industrial setting, the ThermoWorks Hi-Temp Industrial IR With Circle Laser is the go-to choice. It’s lauded for its exceptional precision and the capability to calibrate emissivity for accurate readings on a range of material surfaces.

The dependability of the ThermoWorks Hi-Temp Industrial IR With Circle Laser makes it ideal for extreme temperature measurements in industrial environments. Moreover, its robustness and durability make it a trusted tool in harsh conditions. Additionally, adjustable emissivity is of paramount importance in industrial environments as it enables the precise measurement of temperatures for a wide range of materials, thereby facilitating more accurate control and supervision of industrial processes.

Tips for Accurate Temperature Readings

While infrared thermometers come with numerous benefits, correct usage is key to guarantee accurate temperature readings. Below are some tips for proper application, calibration, and grasp of emissivity.

Proper Usage Techniques

To use an infrared thermometer accurately, you need to consider several factors. One such factor is the understanding of the distance-to-spot ratio, which describes the correlation between the diameter of the area under measurement and the distance from the target. A smaller ratio enables more precise temperature readings by focusing on a smaller area.

The optimal distance for holding an infrared thermometer for precise readings is approximately 6 inches away from the temperature inside the target. To achieve an accurate measurement, it is important to:

- Directly aim the infrared thermometer at the object or body part being measured

- Ensure there are no obstructions between the thermometer and the target

- Hold the infrared thermometer at a 90-degree angle relative to the surface being measured

Following these guidelines will help ensure optimum accuracy.

Calibration and Maintenance

For accurate temperature measurements, calibration of an infrared thermometer at different temperatures is recommended. One commonly used calibration method involves using an ice bath. This entails:

- Filling a large glass with ice and water

- Allowing it to reach thermal equilibrium

- Immersing the thermometer in the water without touching the container

- Calibrating the thermometer to read 32°F (0°C) when pointed at the ice bath.

Regular maintenance is also crucial for optimal performance. Potential consequences of inadequate maintenance include inaccurate readings caused by external factors like dust, smoke, or steam, as well as ambient temperature, humidity, and air currents. Improper calibration can also result in inaccurate temperature readings. It is essential to conduct regular maintenance, including cleaning the lens, inspecting for damage, and ensuring proper calibration, to uphold accuracy.

Understanding Emissivity

Emissivity refers to the efficiency of an object in emitting infrared energy as heat. It is the opposite of reflectivity. In the thermometer’s settings, we must consider an object’s emissivity value, as it impacts the amount of infrared energy it emits, ensuring precise thermal readings.

The emissivity on infrared thermometers can be adjusted by setting the emissivity value on the IR sensor until it measures the same temperature as a contact probe. It is important to note that many IR thermometers come pre-set at an emissivity of 0.95, which is generally suitable for most organic objects. However, emissivity values for different materials can differ significantly.

For example, cement has an emissivity value of 0.54, while polished aluminum has a value of 0.05.

Best Thermometer Infrared: Comparing

Infrared thermometers, despite their numerous benefits, may not always be the most suitable tool. We’ll compare them with other types of thermometers, such as contact and probe thermometers, to understand their differences and decide when they could be a more appropriate choice.

Contact Thermometers

Contact thermometers are tools used for temperature measurement that require direct contact with the object or surface. They employ electronic heat sensors to capture temperature data, ensuring precise temperature readings.

Although contact thermometers generally offer higher accuracy compared to non-contact infrared thermometers, they can be more invasive and susceptible to contamination, requiring thorough disinfection after each use. On the other hand, infrared thermometers can measure temperature without physical contact, thereby reducing the risk of contamination.

Probe Thermometers

Probe thermometer is another type of thermometer that utilizes a metal probe to gauge the internal temperature of food or other substances. They are frequently employed in culinary settings to verify that meat reaches the desired level of doneness.

Probe thermometers operate by transmitting an electrical current through a wire in the probe. As the temperature of the food rises, the wire’s resistance changes, and we gauge this variation in resistance to ascertain the food’s internal temperature. Additionally, people mainly use them to measure the internal temperature of food, ensuring it reaches the appropriate temperature for safe consumption and preventing food-borne illnesses.

Common Misconceptions About Infrared Thermometers

Despite the wealth of information available about infrared thermometers, some misconceptions continue to exist. We’ll tackle some of the most prevalent ones and clarify the facts.

Accuracy Concerns

One of the prevalent misconceptions is that infrared thermometers are inaccurate. In reality, several factors can impact the precision of infrared thermometer readings, such as:

- The angle of measurement

- Ambient temperature

- Air quality

- Electromagnetic interference

- Environmental radiation

- The characteristics of the target

Additionally, factors like emissivity, distance-to-size ratio, and the role of the laser pointer also contribute significantly to determining accuracy.

The distance-to-spot ratio of an infrared thermometer fundamentally determines the diameter of the area being measured relative to the distance from the target. A smaller ratio enables more precise temperature readings by focusing on a smaller area, thereby enhancing accuracy. Nevertheless, external factors such as ambient temperature can influence the accuracy of infrared thermometers, which may result in less precise readings. However, the standard margin of error for an infrared thermometer ranges from 0 to 0.3°C, as determined by various studies and manufacturer specifications.

Limitations in Measuring Internal Temperatures

Another common misconception is that infrared thermometers can measure internal temperatures. However, they are designed to measure surface temperatures only. Additionally, they may need adjustments based on the surface being measured and are less accurate compared to surface probes.

Infrared thermometers are unsuitable for measuring internal temperatures in situations such as measuring the temperature of food or liquids, or monitoring body temperature internally. Probe thermometers, on the other hand, measure internal temperatures and are essential tools in culinary and other precise temperature measurement applications. Therefore, it is crucial to understand these limitations to ensure the appropriate application of the device.

Summary of Best ThermometerI

In summary, infrared thermometers are an invaluable tool for measuring temperature in a variety of fields. They offer numerous advantages, including non-contact measurement, rapid readings, and versatility in various applications. However, like any tool, they are not without their limitations and misconceptions. Understanding these can help ensure you’re using the right tool for the job and obtaining accurate readings.

Discover more about thermal imaging cameras by visiting Thermal Imaging Cameras. View the Sper 800102 Infrared Thermometer Gun 8:1, -4 To 930 Deg F to discover more infrared thermometers

Certified MTP offers best thermometer infrared for your projects.

Certified MTP also has numerous options for the thermometers, including Digital Thermometers, Mercury Free Thermometers, and Digital Infrared Thermometers.

Frequently Asked Questions

How does a best thermometer infrared work?

An infrared thermometer works by capturing and directing the infrared rays emitted by an object onto a detector to measure its surface temperature without direct contact.

What are the advantages of using an infrared thermometer?

Using an infrared thermometer allows for non-contact measurement, providing rapid temperature readings without physically touching the surface. This feature offers convenience and efficiency in temperature monitoring.

How can I ensure accurate readings from an infrared thermometer?

To ensure accurate readings from an infrared thermometer, it’s crucial to focus on proper usage, regular calibration, and understanding emissivity. These factors play a significant role in obtaining accurate reading precise temperature measurements.

What is the best thermometer infrared for cooking?

The Cuisinart CSG-200 Infrared and Folding Grilling Thermometer is highly recommended for cooking because of its reliable performance and versatile use.

Can best thermometer infrared measure internal temperatures?

No, infrared thermometers can only measure surface temperatures. For internal temperatures, probe thermometers are used and are more suitable for this purpose.

Related Blogs to Best Thermometer Infrared:

Certified Thermometers for Material Testing

Consistency of Concrete; How It’s Measured, Why It’s Important, and Relation to Workability

28 Days to Testing Concrete for Strength

Materials Testing Experts Explain The Importance Of Concrete Testing

How to Convert 65 Degrees C to F>

Role of Thermometers in Concrete Curing

How to Convert 70 Deg F to C Easily

How to Convert 158 Fahrenheit to Celsius (158 F to C)

Lab Grade Thermometer for Concrete Testing

Thermometers Calibrated: Calibrate for Accurate Readings

Traceable Thermometer: Accurately Measure Temperature

Convert 900 Degrees Fahrenheit to Celsius (900 F to C)

Master C to F Formula: How to Convert Celsius to Fahrenheit

Digital Humidity and Temperature Meter: Discover the Best

7 Fahrenheit to Celsius: Quick Temperature Conversion Guide

75 Fahrenheit to Celsius Converter: Easy Conversion Method

Top IR Gun Models for Accurate Temperature Readings

Easy Guide: Convert 69 Fahrenheit to Celsius Effortlessly

67 F to C: Accurate Fahrenheit to Celsius Conversion Guide

How Do I Check My Temperature with an Infrared Thermometer?

Convert 99.4 F to C: Fahrenheit to Celsius Conversion

Easy K to F Conversion: Your Guide to Kelvin to Fahrenheit

Quick 35 f to c Conversion: Convert Fahrenheit to Celsius

Easy 0 F to C Conversion: Turn Fahrenheit into Celsius Fast

60 Degrees C to F: Quick Conversion Guide

32 Celsius to Fahrenheit: Easy Temperature Conversion Guide

How to Convert 79 Degrees F to C Easily [Conversion Solved]

Temperature Conversions Table: Fahrenheit to Celsius

Celsius to Kelvin: Guide to Accurate Temperature Conversion

Fahrenheit to Rankine Formula: Steps for Temp Conversion

Quick and Easy Celsius Calculator for Temperature Conversion

Rankine to Celsius Conversion: Your Complete R to C Guide

K to Rankine Conversion: Master the Temperature Scales

Best Thermal Imaging Cameras for Ultimate Precision

Discover the Best Type of Thermometers for Accurate Readings

How to Read Digital Thermometer for Accurate Results

Disinfecting Thermometer Methods: Accurate and Safe Readings