How often do we drive on roads and parking lots without giving much thought to the science and precision behind their construction? Asphalt testing is a crucial aspect of ensuring high-quality, durable roads and pavements, and this blog post will delve into the fascinating world of asphalt testing and analysis. From core drilling and asphalt binder properties to laboratory techniques and adherence to testing standards, readers will gain a comprehensive understanding of the meticulous process behind the surfaces we traverse daily.

Key Takeaways for Asphalt Testing

- Essential asphalt testing for 2023 road surfaces includes core drilling and sample collection, the coring process, and adherence to testing standards.

- Asphalt binder properties are critical factors in determining pavement performance. Common tests measure the softening point as well as specific gravity of asphalt samples.

- Laboratory techniques such as moisture susceptibility testing and wheel tracking devices help evaluate mixtures for optimal performance & durability.

Core Drilling and Sample Collection

Analyzing the properties of asphalt pavements accurately is a key step to ensuring their quality and durability. A crucial step in this process is obtaining pavement samples using a core drilling machine. These samples allow for the evaluation of various properties, such as:

- viscosity

- ductility

- flash point

- softening point

These properties are vital in determining the performance and longevity of asphalt materials.

A thorough comprehension of asphalt pavement properties allows engineers to make educated choices about the materials employed.

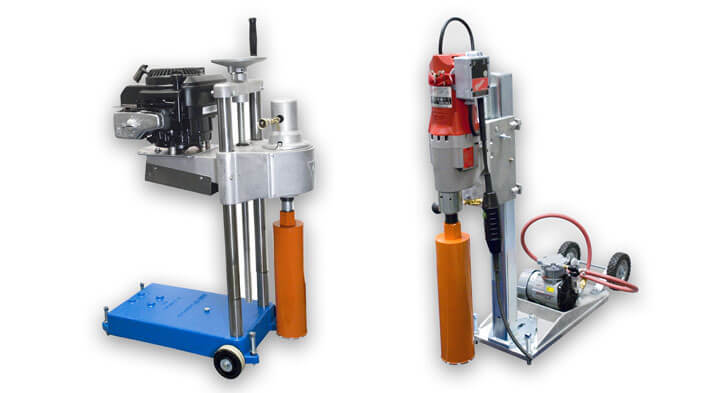

Core drilling machine

The core drilling machine plays a vital role in extracting cores from asphalt pavement samples for testing purposes. It typically consists of a diamond-tipped drill bit, a motor, and a vacuum system. The machine creates a cylindrical hole in the asphalt pavement, and the vacuum system extracts the core sample, which is then used for further analysis and testing.

The accuracy of the samples and the reliability of the test results depend heavily on the precision of this equipment during the sample preparation process.

The coring process

The coring process is a series of steps that involve using a hollow drill to bore holes and extract cylindrical cores or samples from various surfaces, such as concrete or asphalt. Choosing the right location and depth for sample collection is vital, as it affects how accurately the core sample reflects the evaluated material’s properties.

Setting up the core drilling machine and drilling the hole is followed by extracting the core sample. Adhering to the correct coring process allows asphalt professionals to obtain accurate samples that represent the pavement, resulting in reliable and meaningful test results.

Ensuring accurate core samples

The accuracy of core samples is crucial for obtaining dependable results from subsequent asphalt tests. Factors that significantly influence the accuracy of core samples include the type of core drilling machine used, the coring process, and the quality of the core sample itself.

Accurate core samples prevent erroneous results from subsequent asphalt tests, ensuring that the right decisions are made about the asphalt mixture and its performance.

Asphalt Binder Properties and Testing

Asphalt binder is a vital component in asphalt mixtures, and its properties significantly impact pavement performance. Some of these properties include:

- Content

- Softening point

- Viscosity

- Elasticity

- Aging characteristics

These properties, along with other properties, affect the stiffness, strength, durability, fatigue life, surface raveling, and rutting of Hot Mix Asphalt (HMA) mixtures.

To evaluate these properties, various tests are employed, such as the Dynamic Shear Rheometer and Bending Beam Tester.

Asphalt binder content

The asphalt binder content in asphalt mixtures plays a significant role in determining pavement performance. It influences the following aspects of HMA mixtures:

- Stiffness

- Strength

- Durability

- Fatigue life

- Raveling

- Rutting

Optimizing the asphalt binder content in a mixture, with a thorough understanding of its importance, can lead to robust and long-lasting asphalt pavement.

Softening point

The softening point of asphalt binders is the temperature at which the binder begins to transition from a solid to a semi-liquid state. This property is indicative of the binder’s resistance to deformation and its ability to maintain pavement durability. The softening point temperature is determined using a ring and ball apparatus, which measures the temperature at which the asphalt binder starts to soften and flow.

The outcomes of softening point testing are crucial in assessing the asphalt binder’s resistance to deformation and its capacity to sustain pavement durability. Knowing the softening point of an asphalt binder helps pavement professionals to choose the most fitting binder for specific applications, thus optimizing pavement performance.

Common asphalt binder tests

Various tests are used to evaluate asphalt binders, including:

- Penetration Test

- Ductility Test

- Thin-Film Oven Test

- Bending Beam Rheometer Test

- Direct Tension Tester

- Dynamic Shear Rheometer Test

These tests assess properties such as viscosity, flexibility, and flash point, which are critical in understanding the performance of asphalt binders.

Conducting these tests aids asphalt professionals in making well-informed decisions about the ideal binder for their specific requirements, resulting in superior performance and durability of pavements.

Laboratory Techniques for Evaluating Asphalt Mixtures

Asphalt testing involves various laboratory techniques to analyze and do asphalt tests to assess the performance and durability of asphalt mixtures. These methods allows us to determine various properties such as:

- Density

- Stability

- Durability

- Resistance to deformation and cracking

The results from the tests are essential in helping us design the most suitable asphalt for the job. Understanding and evaluating these properties enables pavement professionals to confirm that the asphalt mixtures used in road construction are able to withstand loads and environmental conditions.

Asphalt testing is an important part of the road construction process, as it helps to ensure

Specific gravity testing

Specific gravity testing is a crucial method used to determine the density of asphalt test samples. It involves the following steps:

- Collecting a sample of the asphalt mixture

- Weighing the sample

- Determining the volume of the sample

- Placing the sample in a container

- Calculating the specific gravity by dividing the weight of the sample by its volume.

Specific gravity testing plays a crucial role in gauging the quality of asphalt pavement. It is used to calculate the density of asphalt mixtures and to determine the amount of asphalt binder in the mixture. This test ensures that the asphalt pavement is strong and durable, capable of withstanding the demands of traffic and environmental conditions.

Mix design methods

There are various mix design methods available for determining the appropriate proportions of the components in an asphalt mixture, such as:

- Trail and Adjustment method

- British Doe Method

- ACI Method

- Marshall Mix Design Procedure

- Concrete Mix Design Procedure

These traditional methods have been used for many years to create asphalt mixtures with the desired properties and characteristics.

However, newer approaches like the Superpave mix design have emerged, offering more precise and accurate, cost-effective, and time-efficient solutions compared to traditional mix design methods. Superpave mix design is based on the use of performance-graded asphalt binders and laboratory testing to identify the ideal asphalt binder content and aggregate gradation for a given the mix design.

Superpave mix design

The Superpave mix design method provides a more reliable and efficient approach to creating high density top-performance asphalt pavements. It offers a more consistent and dependable asphalt mixture that is better equipped to withstand traffic and environmental conditions.

The Superpave mix design method, which incorporates performance-graded asphalt binders and laboratory testing, allows for precise predictions of pavement performance and durability, resulting in roads and pavements of higher quality and longevity.

Assessing Pavement Performance and Durability

Evaluating the performance and durability of asphalt mixtures is crucial in ensuring that they meet specific requirements for load and environmental resistance. Various tests, such as moisture susceptibility, laboratory wheel tracking devices, and theoretical maximum specific gravity, are utilized to assess pavement performance.

Understanding the results of these tests enables pavement professionals to make informed decisions on the ideal asphalt mixtures for their specific needs, thereby ensuring optimal pavement performance and durability.

Moisture susceptibility testing

Moisture susceptibility testing is a critical method used to assess the ability of asphalt concrete paving materials to resist damage caused by moisture. This test involves subjecting asphalt mix samples to cyclic pressures and repeated pulses of water to evaluate their performance and durability under various moisture conditions.

The importance of moisture susceptibility testing in predicting pavement deterioration and longevity cannot be overstated. Interpreting the results of this test enables pavement professionals to make smart decisions about the best asphalt mixtures for their specific needs, thereby ensuring optimal pavement performance and durability.

Laboratory wheel tracking devices

Pavement professionals use laboratory wheel tracking devices to simulate tests assessing Hot Mix Asphalt (HMA) qualities by rolling a small loaded wheel device. These tests measure bituminous sample deformation resistance to permanent deformation.

Although more economical than conventional methods, these devices have limited ability to precisely emulate real-world conditions. Nonetheless, they provide valuable insights into asphalt mixture performance under simulated conditions, aiding informed decisions.

Theoretical maximum specific gravity (Gmm)

Theoretical maximum specific gravity (Gmm) is a measure of the maximum density of material in an asphalt mixture. Gmm is used to calculate the air voids content in asphalt mixtures, which is essential for evaluating the performance and longevity of the asphalt.

Pavement professionals can create strong, durable asphalt pavement that can handle traffic and environmental conditions by understanding and optimizing other properties of the Gmm in asphalt mixtures.

Adhering to Asphalt Testing Standards

Adhering to established testing standards and guidelines for asphalt materials and pavements is critical for ensuring quality and consistency in results. Adherence to these standards ensures that the tests are conducted fairly and impartially, yielding accurate and reliable results.

This ensures that the asphalt materials used in road construction meet the necessary requirements to withstand loads and environmental conditions, ultimately leading to better-performing and more durable pavements.

Importance of testing standards

Testing standards play a vital role in providing a uniform and consistent basis for conducting tests, determining the criteria and guidelines that must be adhered to during the testing process. They establish benchmarks and assess performance, allowing for a critical evaluation of the quality and effectiveness of products or processes.

Adherence to testing standards helps pavement professionals obtain accurate and reliable results, leading to more informed decisions and improved outcomes in road construction projects.

Common testing standards

Widely accepted testing standards, like ISO/IEC/IEEE 29119 Software Testing, ensure consistency and reliability in asphalt testing worldwide. Standards such as ISO/IEC 25000:2005 (SQuaRE) and ASTM Physical and Mechanical Testing Standards provide a shared framework for communication. They facilitate collaboration among stakeholders involved in testing, ensuring consistent and reliable results across different projects and locations.

Ensuring compliance with standards

To maintain compliance with testing standards, proper equipment calibration and technician training are essential. Testing conditions can introduce variability that can affect the accuracy of asphalt test results, while improperly calibrated equipment can result in inaccurate readings. Furthermore, the proficiency and experience of the technician conducting the test play a significant role in guaranteeing the reliability of the results.

Pavement professionals can ensure accurate and reliable test results for asphalt materials and pavements by adhering their materials to best practices and ensuring compliance with testing standards. This ultimately leads to better-informed decisions in the design and construction of roads and parking lots, ensuring optimal pavement performance and durability.

Summary

Asphalt testing is crucial for ensuring the quality and durability of roads and pavements through intricate processes and standards. Core drilling, sample preparation, and laboratory techniques provide essential data for pavement professionals to make informed decisions. Adhering to testing standards, these methods help determine the most suitable asphalt mixtures for specific needs. By optimizing asphalt binder content, softening point, mix design, and Gmm, professionals ensure strong, durable pavement. The resulting asphalt can withstand traffic demands and various environmental conditions effectively.

In conclusion, this method offers valuable insights into the science behind the surfaces we traverse daily. By adhering to established testing standards, pavement professionals can ensure accurate and reliable results. This leads to the construction of better-performing, more durable roads and parking lots. The next time you drive on a smooth road, appreciate the meticulous process behind its creation.

Certified MTP has an elite selection of Mix Marshall Design tools and equipment, showcasing industry-leading brands for Marshall Stability Test Systems, Marshall Compactor Test Equipment and Molds, Marshall Water Baths for Asphalt Testing, and Sample Ejectors for Asphalt Extrusion.

Frequently Asked Questions

How do you test for asphalt?

Testing asphalt involves using Asphalt Content Testers to determine percentage of asphalt, Viscometers to see thickness and measure viscosity, and Penetration Test Apparatus to assess consistency. All these tests allow for accurate assessment of asphalt mixtures.

What are the tests for asphalt durability?

Asphalt durability is commonly tested by methods such as kinematic viscosity, the Superpave Shear Tester, absolute viscosity, HMA performance tests, mixture characterization tests, flash point, the Asphalt Mixture Performance Test, and binder content.

Why is asphalt testing important?

Asphalt testing is essential to optimize performance, increase pavement lifetime, and predict material property changes to ensure roads are safe and cost-efficient.

What is the purpose of core drilling machines in asphalt testing?

Core drilling machines are essential equipment for asphalt testing, as they are used to collect pavement samples for examination.

Why is the softening point of asphalt binders important?

The softening point of asphalt binders is an important factor, as it indicates the depth and the binder’s ability to withstand deformation and maintain pavement durability.

Related Blogs for Asphalt Testing:

Top Asphalt Testing Solutions for Pavement Performance

Asphalt Testing Equipment: A Comprehensive Guide

Mastering Marshall Testing: A Guide for Quality Asphalt

Benefits of Asphalt Mixer: Mixing Asphalt for Construction

All You Need to Know About Asphalt Thermometers

The Importance of Asphalt Density in Pavement Construction

Asphalt Depth Poker – A Comprehensive Guide

Ignition Oven: A Guide to NCAT Asphalt Content Furnace Tech

Discover the Best Asphalt Core Drill Bit for Your Project

Benefits of Asphalt Binder: A Comprehensive Guide

Rice Testing: Guide to Asphalt Specific Gravity Testing

The Best Guide to Coring Test for Asphalt & Concrete Cores

Understanding the Marshall Test for Asphalt Mix Design

Understand Viscosity of Asphalt: Dynamic and Kinematic

Asphalt vs Concrete: A Comparative Study

Asphalt Rice Testing: Understanding the Equipment and Tests

Understanding the Specific Gravity of Asphalt

Factors That Influence the Quality of Asphalt: 21 Keys

Determining the Specific Gravity of Asphalt with Rice Test

Five Asphalt Repair Tips for Surfaces to Save Time and Money

Top Choice for Bulk Rubber Hose: Durability And Flexibility

Choosing Asphalt Tester: Guide to Reliable Pavement Tests

Asphalt Thermometers: All You Need to Know