When addressing material handling needs, particularly in compact spaces or when precision is paramount, the utility of a jib crane becomes undeniably evident. Whether you’re moving loads between workstations or dealing with heavy lifting, jib cranes offer a customized solution tailored to your operational needs. This article serves as a comprehensive guide to understanding jib cranes, facilitating the right selection for your specific application while upholding the safety and efficiency of your operations.

Key Takeaways

- Jib cranes offer versatility, precise load positioning, and are suitable for confined spaces with various types including freestanding, wall-mounted, articulating, and mast type cranes, each designed to meet specific industrial needs.

- Installation of these cranes demands meticulous planning, strong foundations, and rigorous adherence to safety and structural standards. Regular maintenance and inspections are imperative to ensure longevity, safety, and optimal performance.

- Safety in operating cranes is paramount, with load limits, operator training, and proper use of accessories and customizations being key to prevent accidents and improve efficiency in material handling.

Understanding Cranes: Design and Functionality

Jib cranes, including foundationless cranes, are the embodiment of adaptability and versatility in the realm of lifting devices. Their features include:

- Slim design

- Robust construction

- Effective operation in confined workspaces

- Precise load positioning controls, making them the exact jib crane solution for short-distance material handling

- Ideal for moving materials between workstations

Their simplicity belies their functionality, making them a boon for industries that require efficient material handling.

Technological advancements have not left these cranes untouched. With the introduction of modular, adaptable, and intelligent jib crane systems, automated controls have become the norm, radically enhancing their performance and safety. These innovations have resulted in increased efficiency and reliability, making these cranes an integral part of various industries.

Components of a Crane

The effectiveness of a jib crane lies in the synergy of its primary components. At its core, we find the horizontal part, responsible for load lifting, and the mast or support column, which offers stability and support for the these arm’s rotation. This duo is orchestrated by the trolley, which plays a vital role in transporting loads across the span, running along the crane’s horizontal and vertical beam together, also known as the reach or boom.

When it comes to hoists, these cranes are not one-trick ponies. They are typically equipped with chain hoists, wire rope hoists, and lever or ratchet hoists. Each hoist type is selected based on its suitability for different lifting needs and operational scenarios, making jib cranes adaptable to a wide range of tasks.

How Cranes Work

If you’ve ever watched a jib crane at work, you’ll appreciate the ballet of movements it executes. The fundamental principle underlying the operation of a these crane is its ability to perform arc-like or lateral movements, enabling flexible load positioning and lifting. This trio of movements: rotation, transverse, and lift, powered by the these crane’s motor drive, enable efficient and accurate material handling.

The secret to a these crane’s versatility lies in its rotation capabilities. Lighter capacity applications can be managed with manual rotation, whereas wall and column-mounted these cranes can achieve 180-200° of rotation. The crane height is an important factor when selecting a crane for a specific application. Vertical movement is achieved through a hoist mechanism and horizontal movement through a wall traveling mechanism. These mechanisms enable the crane to access different elevations and reach various locations within the workspace.

In many cases, these cranes are commonly used in conjunction with other equipment, such as overhead cranes, to optimize efficiency by utilizing the these crane’s boom.

Types of Cranes: Choosing the Right Fit

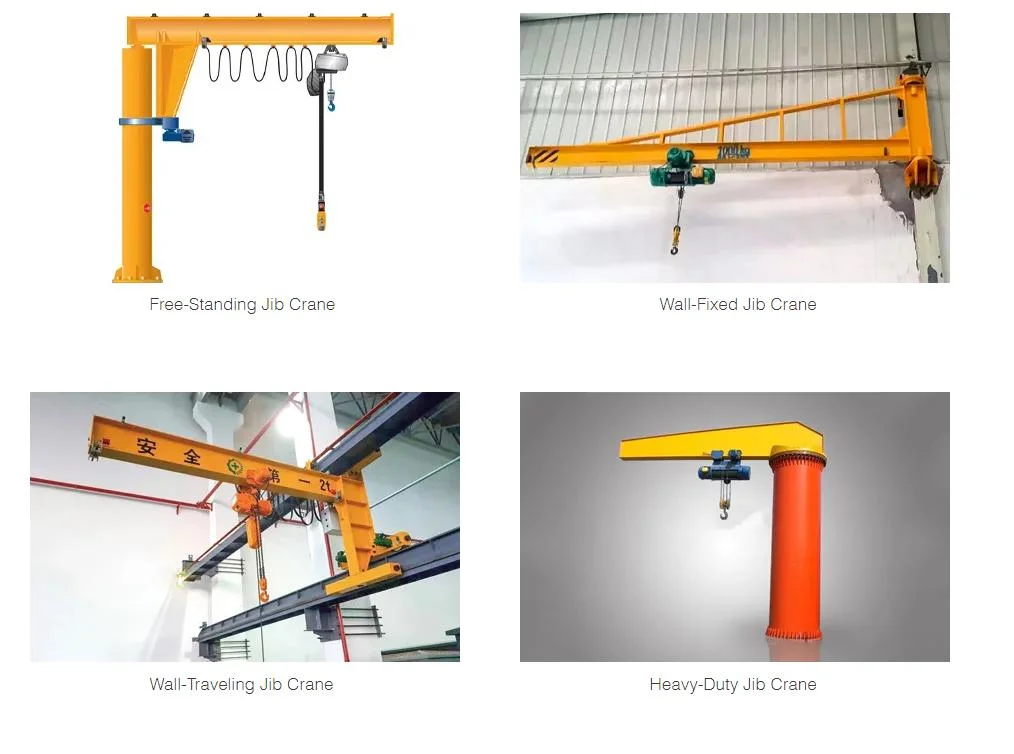

Selecting the right these crane for your needs is akin to choosing the right tool for the job. The market offers a plethora of options including freestanding, wall-mounted, and articulating these cranes, each with distinct features tailored to specific applications. Like a Swiss Army knife, each type of crane has its unique advantages designed to address specific operational needs.

In this article, we will discuss various jib crane types, such as:

- Freestanding cranes, which offer enhanced rotation capabilities and can be tailored with specialized finishes to fulfill specific application needs.

- Wall-mounted cranes, which are specifically designed to save space and navigate around obstructions, making them ideal for compact workspaces.

- Articulating cranes, which have dual swivel arms and offer particular utility in reaching under and into equipment and containers, making them cost-effective choices for specific tasks.

Freestanding Cranes

Freestanding jib cranes offer the following benefits:

- Versatility

- Smooth movement and positioning of loads

- Enhanced productivity

- Capacity to access confined areas

- Support for heavy lifting

- Injury reduction

- Operational and installation flexibility

What sets freestanding cranes apart is their adaptability to both indoor and outdoor environments. Whether it’s in a bustling construction site under the open sky or a tightly packed assembly line indoors, these cranes rise to the occasion. Despite their seemingly delicate design, freestanding cranes are no pushovers. A typical freestanding crane can support a weight capacity of 5 tons, or 10,000 lbs. However, just like any massive structure, they demand their space. Installing a freestanding crane requires consideration of the crane’s capacity, length, and the foundation dimensions.

Wall-Mounted Cranes

Wall-mounted jib cranes, floor and ceiling mounted jib cranes, and wall traveling cranes are the space-savers of the this crane family. These cranes offer the following advantages:

- They are affixed to a building’s vertical support beam, enabling a rotation of up to 180°.

- They provide ergonomic support, alleviating the physical strain and tiredness associated with manual lifting.

- They facilitate the seamless and efficient transportation of loads throughout the hoist’s complete travel range.

Despite their lean profile, wall-mounted cranes pack a punch. A standard wall-mounted jib crane is designed to support a weight capacity of 500 lbs. However, their installation is no small task. These cranes necessitate a load-bearing wall for secure attachment and must depend on existing structures capable of supporting the crane’s weight and operational forces.

Mast Type Cranes

Mast style jib cranes stand out with their unique operation as being floor mounted, supported, top stabilized cranes capable of 360° rotation. The trolley is responsible for carrying the hoist, wire rope or chain, and the hook along the entire length of the boom.

But what truly sets mast type cranes apart are their essential elements, comprising:

- The mast or support column

- The horizontal jib

- The bearing system

- The hoist

- The controls

Despite their solid structure, mast type jib demand a strong foundation. The installation of mast type jib requires a 6’ square by 4’ deep footing, of reinforced concrete depending on the soil pressure at the installation site.

Articulating Cranes

Articulating jib cranes are like the contortionists of the crane family, with their distinctive dual swivel arms that facilitate movement around corners and other overhead obstructions. The benefits of articulating jib include:

- Increased reach and maneuverability

- Ability to lift loads around corners

- Reaching into confined spaces

- Maneuvering around obstacles

These features make articulating jib a versatile and efficient option for lifting and moving loads in various environments, with this articulating crane being a popular choice among users.

However, while they are agile and responsive, articulating these cranes are not designed for heavy-duty lifts. Their typical lifting capacity ranges from under 150 lbs to 500 lbs. While they offer many advantages, their design does not allow for the higher capacity lifts often required for heavy-duty tasks.

Installation and Maintenance Considerations

Installation and maintenance form the backbone of the long and productive life of a jib crane. From the moment of installation to the routine of daily operation, adherence to standardized requirements and regular maintenance is non-negotiable. Whether it’s pouring a strong foundation for a freestanding jib crane or installing the wall bracket for a wall-mounted jib, each step is crucial to the safe and efficient operation of the crane.

Along with the installation, the maintenance and inspection of the jib are equally important. A regular preventive maintenance schedule and routine inspections play a key role in ensuring the longevity and safe operation of the jib crane and should never be neglected.

Installation Requirements

The installation of a crane is a meticulous process that involves careful planning and adherence to stringent requirements. Foundation requirements usually involve a 6’ square by 4’ deep footing for a 1-ton crane with up to a 15’ jib, but these specifications may vary depending on the manufacturer’s guidelines and soil pressure.

Beyond foundation, structural requirements also play a key role. A robust foundation and a support structure capable of withstanding the loads produced by anchor bolt force and potential overturning moments are essential.

Furthermore, the dimensions of the workspace play a crucial role in the installation of a crane. They affect factors such as:

- The dimensions and weight of the load

- Working span

- Span length

- Available height under the boom

The installation processes differ significantly among different types of cranes, each with their unique requirements.

Routine Maintenance and Inspections

Maintenance and inspections are to jib cranes what regular health check-ups are to us. They ensure the crane remains in top working condition, prolong its service life, and prevent potential issues that may lead to equipment failure or accidents. Regular inspections should be conducted at least annually, in compliance with OSHA regulations.

The essential components to examine on a jib crane comprise the cable or chain, the crane structure including the jib, and typical indicators like debris on the runway and structural concerns. These regular check-ups ensure that the crane remains in peak operating condition, contributing to the safety and productivity of the entire operation.

Enhancing Jib Performance with Accessories and Customizations

While a jib crane in its standard form is a powerful tool, with the right accessories and customizations, it can be transformed into a highly specialized lifting solution. From different hoist options and trolley systems to power supply choices, these enhancements can significantly improve a this crane’s performance and adaptability to various applications.

The choice of power supply can have a profound impact on the overall operation of a crane. A consistent frequency supply is crucial for improving the efficiency and reliability of jib crane operations. Inconsistent power can result in motor performance issues and potential malfunctions.

Moreover, trolley systems in cranes have the following features:

- Specifically engineered to support and manage the weight of the boom during its movement

- Maintain a fixed position while the boom rotates

- Enable seamless and effective transportation of the load

Hoist Options

The choice of hoist can make a world of difference in a jib crane’s operation. Some advantages of electric hoists include:

- Reliability and durability

- High task completion efficiency

- Energy efficiency

- Quiet operation

- Fast lifting and lowering speed

- Compact and lightweight design

On the other hand, manual hoists operate by utilizing a mechanical advantage to effectively leverage a small force over a long distance. The choice of hoist depends on the specific lifting applications and requirements of the operation and lifting system.

Trolley Systems

Trolley systems play a key role in enhancing the operational efficiency of a crane. They support and manage the weight of the boom during its movement, maintaining a fixed position while the boom rotates. This enables seamless and effective transportation of the load.

There are various trolley systems utilized in cranes, including standard manual trolleys, electric trolleys, and festoon systems, each tailored to specific operational requirements. Motorized trolley systems, often powered by a crane’s motor drive, provide the benefit of smooth and continuous motion, particularly advantageous for handling heavy loads, reducing the risk of injuries, and enhancing efficiency in material handling operations.

On the other hand, air-powered trolley systems improve load handling by enabling the efficient lifting, lowering, and horizontal movement of medium to heavy loads.

Power Supply Choices

The choice of power supply is a critical factor in the overall operation of a crane. A consistent frequency supply is crucial for improving the efficiency and reliability of jib operations.

Pneumatic power supply, for instance, involves the utilization of a pneumatic cylinder, which is responsible for controlled raising and lowering of the load. However, manual power supply is particularly suitable for hazardous environments, emphasizing the importance of selecting the right power supply based on the application and environment.

Safety Precautions and Best Practices

Safety is paramount when it comes to operating cranes. Understanding load limits and capacity, adhering to safety precautions and best practices, and ensuring proper operator training are crucial for ensuring the safe operation of jib cranes.

Load Limits and Capacity

Understanding and adhering to load limits and capacity is non-negotiable when it comes to safe jib operation. The load limit and capacity for standard jib cranes are determined based on a design load, which includes the capacity rating of the overall jib crane height, plus 15 percent of the capacity for the weight of the hoist.

Exceeding these limits can lead to significant hazards, including the risk of the crane toppling over, potentially causing severe injuries or fatalities. It also puts the lift system at risk, posing a danger to the operators and others in the surrounding area.

Thus, operators can ensure compliance by implementing a limiting device for cranes with a lifting capacity of 5,000kg or more and adhering to rated load limits.

Operator Training

Proper operator training is an essential aspect of safe and efficient crane operation. In order to operate a jib crane, individuals must:

- Acquire certification from a recognized crane operator testing organization like OSHA

- Pass the NCCCO’s Written and Practical examinations

- Be at least 18 years old

- Possess the physical capability to meet the demands of the job

Key competencies for the safe and effective operation of a crane encompass:

- Excellent hand-eye coordination

- Attention to detail

- Capability for regular inspections

- Understanding of machine and tool usage

- Good teamwork

- Patience

- The ability to remain composed under pressure.

The typical duration for training a new jib operator is approximately forty minutes, encompassing practical exercises such as:

- Pre-operational inspection

- Load hook and chain placement

- Negotiating zigzags

- Tight space navigation with a load

- Learning OSHA standard hand signals

- Performing blind lifts

- Mastering load settling

Summary

In conclusion, jib cranes are versatile and adaptable lifting devices that play a crucial role in various industries. By understanding their design, functionality, types, and key considerations when selecting and operating a jib, you can ensure their safe and efficient operation. Remember, the right crane, with the right accessories and customizations, operated in the right way, is a powerful tool that can elevate the productivity and safety of your operation to new heights.

Certified MTP offers tools, supplies, and equipment for Warehouse Supplies, such as Cranes, Gantry Cranes, Jib Cranes, and A Frame Cranes.

Frequently Asked Questions

What is a jib used for?

The jib is a sail located at the front of the boat, and it increases the boat’s speed by catching more wind. It also provides stability and improves the performance of the boat by reducing turbulence on the leeward side of the main sail.

What is the difference between a jib crane and a gantry crane?

In conclusion, the main difference between a jib crane and a gantry crane is that gantry cranes are used for moving heavy weights over long distances, often in large industrial settings like factories and seaports, while jib cranes are more suited for smaller weights over shorter distances, particularly in tight workspaces.

What is the significance of jib crane?

The jib crane is significant in industrial settings as it supports a movable hoist and provides floor space for additional lateral movement, typically swinging through an arc.

What is the difference between a boom crane and a jib crane?

The key difference between a boom crane and a jib crane is that a jib crane increases the boom length of a mobile crane while reducing lift capacity as it extends the reach of overhead crane, making it suitable for projects requiring materials to be lifted to great heights or over great distances.

What is the jib of a crane?

The jib of a crane is the horizontal or near-horizontal beam used to support the load clear of the main support. It is an operating arm that extends horizontally from the base plate of crane (Wikipedia).