When it comes to evaluating concrete strength and integrity, the Hammer Schmidt or Schmidt hammer is an essential instrument. Our guide dives directly into the various types of Schmidt rebound hammers used, their applications, and the methodology behind the Rebound Hammer Test, providing insights and practical tips for professionals in the field.

Key Takeaways

- The Schmidt hammer, a non-destructive testing tool invented by Ernst Schmidt, is used globally for estimating the compressive strength of concrete based on the rebound hammer test principle.

- Various factors such as the concrete’s surface condition, texture, moisture content, and aggregate composition can significantly influence the Rebound Hammer Test results, highlighting the necessity for careful test preparation and execution according to standards.

- While the Rebound Hammer Test is valuable for its quick and non-invasive strength assessments, its limitations warrant the combined use with other tests like Ultrasonic Pulse Velocity and Core Tests to obtain a comprehensive analysis of concrete quality.

The Hammer Schmidt: A Brief History

A Swiss engineer with a knack for invention, Ernst Heinrich Wilhelm Schmidt, is the creator of the Schmidt hammer, also known as the concrete test hammer. A trailblazer in the realm of engineering thermodynamics, Schmidt is also known for his contributions in heat and mass transfer. However, it is the Schmidt hammer, a tool that has become synonymous with concrete test hammers, for which he is most recognized.

Proceq introduced this ingenious invention to the commercial market in the 1950s, and with time, it has become the global go-to tool for non-destructive concrete strength evaluations, otherwise known as the rebound hammer test.

Types of Hammer Schmidt Devices

A range of Hammer Schmidt devices, including schmidt hammers, are available, each tailored for distinct testing needs. These include the original schmidt hammer, Rock Schmidt, and Silver Schmidt, each carrying unique specifications and functionalities.

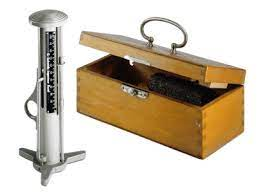

Original Schmidt

The Original Schmidt device is the backbone of the Hammer Schmidt family and is commonly used to assess the compressive strength and homogeneity of concrete and other materials. Operating on the principle of rebound, it utilizes a spring-driven hammer that strikes the concrete surface, measuring the rebound distance to estimate the compressive strength of the material.

This device has gained popularity for its versatility, finding applications in on-site testing of concrete strength, non-destructive assessments of structural strength, and rebound testing of hardened concrete for quality measurement. While it uses the R-value for measurement, later versions like the Silver Schmidt employ Q-value measurements, offering more options for evaluating concrete strength.

Rock Schmidt

The Rock Schmidt, a specialized variant, is designed for assessing the hardness, strength, and consistency of rock formations in engineering contexts. The functionality of the Rock Schmidt is based on the same rebound principle, deploying a spring-loaded mass to impact a plunger against the rock surface and measuring the rebound distance to ascertain the rock’s hardness or strength.

What sets the Rock Schmidt apart is its unique optical measurement system, offering accurate correlations for rock testing applications. Its features include:

- Impact angle independence

- High accuracy

- Durability

- Wide measuring range

These qualities make it an ideal choice for testing various rock types and strengths.

Silver Schmidt

The Silver Schmidt, a more advanced model in the Schmidt hammer lineup, stands out due to its:

- True rebound value calculated from the impact velocity quotient

- Suitable for concrete testing

- Specifically designed for rock testing

- Improved accuracy and measurement reliability

- Enhanced performance in concrete strength assessment

The Silver Schmidt is widely recognized for its precise measurements and consistent repeatability in assessing the strength of concrete, particularly in situations where precise testing results are essential. Although the specific technology utilized for non-destructive concrete strength assessment without coring is not explicitly disclosed, its advanced features indicate a refined approach to ensuring precise strength assessments across diverse testing conditions.

The Rebound Hammer Test: Purpose and Methodology

The Rebound Hammer Test primarily aims to evaluate the compressive strength of concrete structures without causing them any damage. This test, performed using a Hammer Schmidt device, measures the surface hardness of concrete to provide an estimate of its strength.

The process of conducting a Rebound Hammer Test involves several crucial steps:

- Preparation of the test surface

- Calibration of the Rebound Hammer

- Conducting the test

- Collecting and calculating data to ascertain the concrete’s strength.

Central to the test is the concept of a rebound number, which denotes the rebounding mass’s elasticity following its impact on the concrete, providing a measure of the surface hardness lower strength and overall quality of the concrete being tested.

Factors Affecting Rebound Hammer Test Results

Multiple factors relating to the concrete’s surface condition, including temperature, humidity, and moisture content, can sway the Rebound Hammer Test’s results. For instance, elevated moisture levels in the concrete can diminish the rebound values, resulting in a lower estimated compressive strength.

On the other hand, the type of aggregate and cement used in the same concrete can also significantly affect the test results. The water-cement ratio, the impact of carbonation, and the curing conditions may all influence the rebound values, hence affecting the accurate assessment of concrete strength.

Preparing for a Rebound Hammer Test

Appropriate preparation is key to obtaining precise results from a Rebound Hammer Test. Here are some steps to follow:

- Select test locations in accordance with the ASTM C805 standard to ensure a thorough representation of rebound numbers throughout the structure.

- Ensure that the concrete surface is smooth, clean, and dry.

- Remove any loose material from the surface, often using a grinding wheel, to guarantee accurate test results.

By following these steps, you can ensure that you obtain accurate and reliable results from your Rebound Hammer Test.

Surface texture and moisture content are two critical factors in test preparation. Here are some key points to consider:

- A rough texture can yield different rebound numbers compared to a smooth surface, thereby influencing the assessment of strength.

- Dry concrete surfaces produce more consistent and higher rebound numbers.

- Tests conducted on wet surfaces may result in an underestimation of concrete strength.

These and other factors should be taken into account when conducting concrete strength tests on a concrete structure.

Interpreting Rebound Hammer Test Results

The interpretation of a rebound hammer test’s results requires a chart correlating the concrete and rebound number. It’s important to understand the relationship between compressive strength and rebound number. Generally, higher compressive strength tends to yield higher rebound number values.

In essence, elevated rebound and energy numbers in rebound hammer tests, conducted using rebound hammers, typically signify greater compressive strength of the concrete. On the flip side, lower rebound numbers may indicate lower impact energy and potentially less damage to the surface being tested.

Pros and Cons of Using Hammer Schmidt Devices

Hammer Schmidt devices have various benefits such as:

- their ability to estimate in-place concrete’s compressive strength

- their cost-efficient method of evaluating structure condition

- their reliability in delivering trustworthy results when used correctly

However, they do have their limitations.

The primary drawbacks of utilizing Hammer Schmidt devices include:

- Delay in obtaining results as they are not immediate

- Concrete in specimens may have properties different from the concrete in the actual structure

- Accuracy limitations due to factors such as moisture content and surface condition, which can affect the results

- Error margin in the utilization of Hammer Schmidt devices for assessing concrete strength can vary between 10-20%, signifying notable limitations, particularly in cases involving thinner concrete cross-sections or ‘green’ early-age concrete with lower strengths.

Combining Rebound Hammer Test with Other Testing Methods

Combining the Rebound Hammer Test with other testing procedures can provide a more reliable evaluation of concrete quality and strength, presenting a holistic analysis from multiple perspectives. For instance, the combination of Rebound Hammer Test and Ultrasonic Pulse Velocity Test enhances concrete analysis by offering insights into compressive strength, structural performance, and overall quality.

Similarly, the Carbonation Test complements the Rebound Hammer Test by providing insights into the impact of carbonation on the rebound number and the development of concrete strength. Additionally, integrating Rebound Hammer Test with Core Test offers advantages in terms of cost-effectiveness, rapid assessments, and efficient evaluation of in situ concrete strength.

When integrating Rebound Hammer Test with Chloride Ion Penetration Test, it’s crucial to consider the following:

- Rebound Hammer Test assesses surface hardness

- Chloride Ion Penetration Test evaluates chloride concentration at various depths

- The combination of these tests offers a comprehensive understanding of surface hardness and chloride penetration profile.

Summary

In summary, the Hammer Schmidt devices and the Rebound Hammer Test method have made significant strides in the field of concrete testing. Despite some limitations, these tools have proven their worth in assessing the compressive strength and quality of concrete structures in a non-destructive manner. By understanding the factors affecting the test results and integrating other testing methods, professionals can derive more accurate and reliable results, ensuring the longevity and safety of the structures we live, work, and play in.

Certified MTP has the largest selection of concrete testing supplies, showcasing industry-leading brands for Concrete Test Rebound Hammers, Original Schmidt Concrete Test Hammer Type N, Non-Destructive Concrete Testing Supplies, and fresh concrete testing equipment.

Frequently Asked Questions

What is a Schmidt hammer test?

A Schmidt hammer test is a method using a device to measure concrete or rock strength by assessing its rebound number based on the impact of a spring-loaded mass on the surface. It was invented by Ernst Heinrich Wilhelm Schmidt, a Swiss engineer.

Is Schmidt hammer accurate?

No, the Schmidt hammer is unable to give a reliable estimate of concrete strength due to a large dispersion and low strength of data in in situ investigations. Therefore, it is not accurate to rely solely on the Rebound Hammer for strength estimates.

What are the different types of Schmidt hammers?

The different types of Schmidt test hammers include the Original Schmidt Hammer, Silver Schmidt, Schmidt Live, and Rock Rebound Test Hammers. They are available in analog versions or with electronic measurement systems and data management features.

What strength is the rock Schmidt hammer?

The rock Schmidt hammer has a compressive strength ranging from 2,900 to 21,750 psi, making it suitable for a wide range of rock types.

Who invented the concrete test hammer?

Ernst Heinrich Wilhelm Schmidt, a Swiss engineer, invented the concrete test hammer, also known as swiss hammer or the Schmidt hammer.

Related Blogs for Hammer Schmidt :

Correctly Measure Cracks and Fissures with a Concrete Testing Product

What is Non-Destructive Testing of Concrete?

Ultrasonic Pulse Velocity Test | Concrete Non-Destructive

Understanding Non Destructive Test: Methods & Applications

Crack Measurement in Concrete: A Guide to Accurate Results

Penetration Resistance Test: Assess Construction Materials

Unlocking Non Destructive Testing: Methods and Insights

Windsor Probe Test: Accurate Concrete Strength Assessment

Concrete Hammer Testing: Evaluating Concrete Strength

Protection with Waterproof Epoxy Glue: Your Bonding Solution

Unlocking Non Destructive Testing: Methods and Insights

A Guide to Concrete Tests and Non-Destructive Testing (NDT)

Concrete Testing: Non-Destructive Testing for Lab and Field

Testing Equipment for Concrete: Non-Destructive & Field Test

NDT Equipments: An Overview of Non-Destructive Testing

What Is Non-Destructive Evaluation: The Complete Guide

Non-Destructive Test of Concrete

Best Concrete Crack Gauge: Guide to Accurate Monitoring

Concrete Water Permeability for Durability and Performance

Decoding the Surface: Is Concrete Porous or Nonporous?

Top Concrete Strength Testing Methods: Structural Integrity