If you’re involved in road construction, understanding the California Bearing Ratio test is essential for designing stable roadways. This test provides a numerical value indicating the strength of the soil by simulating the stress it can withstand, which is critical for ensuring the foundation can support traffic over time. In this guide, we’ll explain the California Bearing Ratio test procedure, how its results inform road design, and its practical applications in construction projects, offering you insights into its pivotal role in infrastructure development.

Key Takeaways

- The California Bearing Ratio test (CBR) is a crucial measure of soil strength and load-bearing capacity used in road construction, providing CBR values that assess the subgrade strength of roads and pavements for informed engineering decisions.

- California bearing ratio test procedure includes preparing and soaking soil specimens, penetration testing with precise measurement of loads, and both laboratory and field testing scenarios that provide data critical for validating soil conditions and informing construction practices.

- The California bearing ratio test is widely used in road and airport runway design, guiding pavement thickness and subgrade strength estimations. However, it faces challenges such as result variability and limitations. These issues have led to the consideration of alternative methods, like the Dynamic Cone Penetrometer, for potentially more accurate soil strength assessments.

Understanding the California Bearing Ratio Test (CBR)

The California Bearing Ratio test (CBR) serves as a measure of the strength and load-bearing capacity of soil used in road construction. It’s like a health check-up for the soil, determining whether it has what it takes to bear the weight of our commuting habits. The CBR value, expressed as a percentage, indicates how much stress a soil sample can endure compared to a standard soil composition. Imagine a soil sample as a rookie weightlifter, and the CBR test as the coach assessing the rookie’s ability to lift weights compared to a seasoned professional.

Rather than just producing numbers, this test provides a comprehensive understanding of the soil’s strength and load-bearing capacity, essential for assessing the subgrade strength of roads and pavements. Engineers rely on these CBR values to assess the subgrade strength of roads and highways, and to make informed decisions in road construction and pavement design. You might be wondering how these values are obtained. To grasp this, we need to journey back and unravel the origins of the CBR test and its integral components.

Development and Adoption of California Bearing Ratio Test

In the 1930s, the California Division of Highways planted the seeds of the California bearing ratio test. They designed the test to ensure the construction of economically viable pavements capable of handling the increasing road traffic and anticipated axle loads. By 1935, California had officially adopted the CBR test, reinforcing its importance in transportation infrastructure.

However, California wasn’t the only place that recognized the value of this test. Its effectiveness in assessing soil strength, simplicity, cost-effectiveness, and the valuable insights it offers for road design and construction led to its adoption by agencies worldwide. Today, the California Bearing Ratio test is recognized by:

- State Departments of Transportation

- Federal Highway Administration

- Federal Aviation Administration

- Standardized as AASHTO Test Method T193.

Key Components of the CBR Test

Each component of the CBR test plays a significant role, making it function seamlessly like a well-oiled machine. The process begins in the laboratory with the creation of test specimens from project-specified test material, which are then compacted and soaked. The test accommodates a range of materials, including cohesive soils with particles under 19mm and various granular soils and aggregates.

After compacting the specimens, soak them for 96 hours with a surcharge weight to simulate pavement weight and potential rainfall, representing adverse moisture conditions during service. Then, conduct penetration testing at a rate of 0.05 inches per minute, recording loads at specific intervals to determine CBR values. However, matching field and laboratory soil saturation can be challenging, often resulting in a lack of the near-total saturation of lab specimens in field CBR tests.

CBR Test Procedure: Step-by-Step Guide

To delve deeper into the procedure, the CBR test involves:

- Compacting a soil specimen in a mold

- Immersing it in water

- Subjecting it to an escalating load using a loading machine

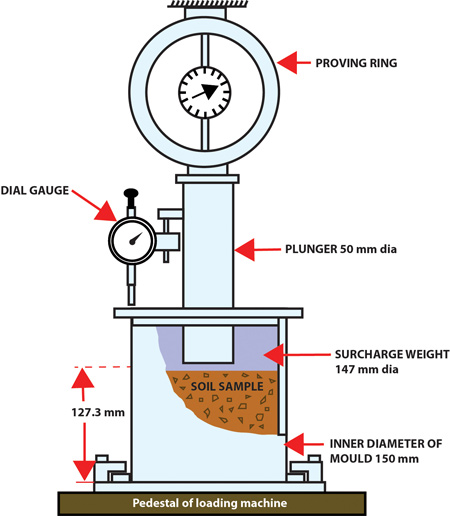

- Using a cylindrical plunger of 50mm diameter to penetrate the pavement material at a constant rate

- Meticulously recording load values at 2.5mm and 5mm penetrations for analysis.

What distinguishes this process in a laboratory from that in a field setting? Let’s examine these two scenarios.

Laboratory CBR Testing

In a laboratory setting, the CBR test employs a range of specialized equipment to test soil samples. The process includes the following steps:

- Sieve the soil sample through a 20mm IS sieve.

- Mix the soil sample with water to reach the optimum moisture content or field moisture content.

- Divide the mixture into five equal parts.

- Compact each layer of the mixture in the mold using a hammer with 56 evenly distributed blows.

After compaction, the mold gets secured to a base plate, and surcharge weights are positioned on the soil surface prior to testing. The testing machine applies a seating load to establish contact between the soil and penetration plunger, with loads recorded at various penetration depths up to 12.5mm.

The soaked CBR test procedure, which involves soaking specimens for 96 hours, helps simulate adverse moisture conditions from potential rainfall or flooding and assess soil strength under such conditions.

Field CBR Testing

While laboratory testing provides valuable data, it is in the field where the rubber meets the road. Field CBR testing serves to validate laboratory results and determine the in-place conditions of soils and bases. The test can be conducted using a standard-size penetration piston or a dynamic cone penetrometer (DCP), which allows for immediate in-situ strength estimates.

Field CBR testing requires a complete set of equipment, including a modified load frame, a CBR Field Test Set, and a loaded dump truck for imposing the test loads. The test set includes key components like loading jacks with varying speed options and capacities, load rings with precise indicators, penetration pistons with extension sets, surcharge plates and weights for simulating loads, and dial support bridges that meet ASTM and COEs standards.

Analyzing CBR Test Results

After conducting the CBR test, the real work begins. Analyze the results by plotting load values against penetration test values and then correct the results according to the standard test procedure to evaluate material strength characteristics. Derive the CBR value from the stress at the 0.100 in (2.54 mm) penetration depth or at the 0.200 in (5.08 mm) depth if the values are similar.

Determine the CBR value by measuring the pressure needed to penetrate the soil sample, dividing it by the standard material’s pressure at the same penetration, and multiplying it by 100 to express it as a percentage.

This percentage indicates the relative strength and stability of the soil subgrade for supporting loads. It is important to note that careful planning and interpretation of CBR test results are essential for obtaining accurate data. This data is crucial for road design and construction projects.

You may wonder how to analyze these results in depth. Let’s break down this process.

Load-Penetration Curve Analysis

A key part of the analysis is the load-penetration curve, which shows the material’s behavior and strength. This curve is made by plotting load values against penetration test values, using a specific method.

The analysis of this curve allows engineers to determine the material’s maximum load-bearing capacity, its elasticity, and the rate of deformation.

Calculating CBR Values

The process of calculating the CBR value is another integral part of the CBR test analysis. The measured pressure needed to penetrate a soil sample is compared with the pressure required for the same penetration in a standard load obtained from crushed rock material. This comparison helps in understanding the characteristics of the soil sample. Standard load values for CBR calculations correspond to specific penetrations at:

- 2.5mm

- 5mm

- 7.5mm

- 10mm

- 12.5mm

These values are provided in a referenced standard table.

To calculate the CBR value, the ratio of the load measurement to the standard load value of standard material at an identical deformation level is expressed as a percentage. High CBR values signify harder surfaces with better load-bearing capacity. For instance, typical quality sub-base materials show CBR values between 80-100%, whereas materials such as clays may exhibit CBR values as low as 2%.

Applications of CBR in Road Design and Construction

The CBR test doesn’t exist in a vacuum. Its true value lies in its application in road design and construction. CBR values allow engineers to compare the strength of soil subgrades against a standard reference material, vital for estimating the subgrade strength required to support road construction. State Departments of Transportation, Federal Highway Administration, and Federal Aviation Administration are amongst the key organizations that integrate CBR values in their infrastructure design and assessment guidelines.

Which aspects of design and construction are influenced by these values? Let’s delve deeper.

Estimating Subgrade Strength

Serving as a sort of report card for the soil, CBR values classify subgrade soil conditions by subgrade surface modulus, facilitating road foundation design. Engineers assess soil responses, such as plastic or elastic behavior, using the shape of the load-penetration curve derived from CBR values.

Using CBR values to estimate subgrade strength ensures the soil can support anticipated traffic loads. Plotting a graph of dry density against corresponding CBR values allows interpolation of the CBR value for a specified maximum dry density.

CBR testing evaluates the strength of cohesive materials and granular soils with particle sizes up to 19 mm (0.75 in).

Pavement Thickness Design

In addition to subgrade strength, CBR test results also inform pavement thickness design. Determining the modulus of the subgrade reaction using CBR test results is essential for calculating appropriate pavement layer thickness. The design must consider traffic volume and load distribution, which are directly influenced by CBR values to avert potential structural failures.

CBR values underpin the required pavement thickness by characterizing the relationship between soil strength and the layer thickness needed to support sustained traffic loads. For the pavement foundation layer, a surface modulus above 30MPa is requisite, guided by CBR testing.

Challenges and Limitations of CBR Testing

As with any scientific procedure, the CBR test comes with its own set of challenges and limitations. The estimated within-lab variability of CBR test results is around 8%, which can affect the precision and reliability of pavement design based on these results. The precision of instruments used in CBR testing can influence the test results, with more precise instruments potentially offering reduced variability.

Are there alternatives to the basic CBR test that could potentially yield more accurate results?

Variability in Test Results

Several factors can contribute to variability in CBR test results. This includes the heterogeneity of different soil types, which affects the bearing ratio. Also, the preparation of soil specimens, particularly concerning moisture content, can introduce variability in the CBR test results.

The operator’s proficiency, method of sample preparation, and adherence to standard test methods influence test result consistency, each contributing to significant variability. Moreover, the reproducibility and repeatability of the CBR test itself are often poor, resulting in high variability and questioning the consistency of the data produced. This variability can complicate the establishment of reliable empirical relationships between index testing results, such as Atterberg limits, and grading analysis and CBR values.

Field CBR testing is susceptible to greater variations in results due to uncontrollable fluctuating conditions such as moisture content and actual soil state.

Alternative Testing Methods

Despite the merits of the CBR test, alternative testing methods such as the Dynamic Cone Penetrometer (DCP) offer a swift and portable solution for determining in situ CBR values, boasting simpler operation and setup than traditional CBR testing. DCP has demonstrated higher repeatability with coefficients of variation around 40%, in contrast to CBR’s variability of up to 60% for the same soil at one test location.

DCP is versatile and can accurately predict CBR values for a broad range of soil types, from gravelly sands to clays, and regression models help correlate DCP penetration depth with CBR for better predictability. Portable alternatives such as the PANDA® penetrometer enable rapid on-site soil testing and can estimate CBR values effectively.

Non-destructive testing methods such as LWD, PANDA®, and the Clegg Hammer can gauge the full penetration resistance of the surface, assessing soil characteristics without inflicting damage. These methods can be considered as alternatives to the standardized penetration test.

Case Studies: Real-World Applications of CBR Testing

The real-world applications of the CBR test truly attest to its utility. Highway construction projects use CBR testing to evaluate the soil subgrade strength and determine the required thickness of pavement layers. This method helps ensure the durability and stability of the road. The economic construction of pavements to carry anticipated axle loads relies significantly on CBR values to select pavement and base thicknesses. Field CBR testing helps confirm laboratory test results and assesses the in-situ strength of soil subgrades and base materials in real-world road construction conditions.

In airport runway construction, CBR testing plays a key role in material selection and designing a foundation capable of supporting the heavy loads imposed during aircraft takeoff and landing. After natural disasters, conducting CBR tests on damaged soil subgrade is pivotal to evaluating its bearing capacity, hence enabling engineers to determine necessary repairs to restore road functionality.

Summary

In conclusion, the California Bearing Ratio test is a crucial cog in the wheel of road construction and design. From assessing soil strength to informing pavement thickness design, the CBR test plays a pivotal role in ensuring safe and durable roads. Despite the challenges and limitations, the CBR test’s utility cannot be discounted. Instead, these limitations necessitate constant advancements and alternatives to ensure more accurate and reliable data. As we advance into the future of infrastructure development, the CBR test remains a trusted companion on our journey towards better roads and safer journeys.

Certified MTP has an elite selection of Asphalt Rice Test Equipment, and Soil Testing Equipment showcasing industry-leading brands for California Bearing Ratio (CBR) Equipment, Vibro-Deairator For Rice Test, Autorice Automatic Rice Testing Control System, and Small Oilless Vacuum Pump.

Frequently Asked Questions

What is a good CBR test result?

A good CBR test result is indicated by a high value, which signifies a harder surface. For instance, high-quality sub-base materials usually have a CBR value between 80-100%.

What is the ASTM standard for California bearing ratio test?

The ASTM standard for California bearing ratio test is the laboratory test method in ASTM D1883 and AASHTO T 193, which compares the resistance to penetration of the test specimen to that equal penetration of a “standard” sample of well-graded crushed stone material using a standard-sized piston.

What is the purpose of the California Bearing Ratio (CBR) test?

The purpose of the California Bearing Ratio (CBR) test is to measure the strength of subgrade and construction materials for roads, highways, pavements, and foundations by using soil properties and providing a percentage value indicating soil sample stress resistance.

How are CBR test results analyzed?

Analyze CBR test results by plotting load values against penetration test values, then correct them according to the standard test procedure. Determine the CBR value based on stress at standard loads and specific penetration depths.

What are some challenges and limitations of CBR testing?

CBR testing may face challenges and limitations due to factors like soil type, moisture content, and instrument precision, leading to variability in test results. In addition, alternative testing methods could provide more accurate and non-destructive options for evaluating soil strength and compaction.

Related Blogs for California Bearing Ratio Test:

CBR Testing (California Bearing Ratio): Explained