Understanding the compactness of asphalt is critical for road safety and longevity. That’s where nuclear density testing comes in—offering a robust and non-destructive way to assess material density and moisture levels. But what exactly does the process involve, and why is it the go-to method for industry professionals? This article will guide you through the mechanics, usage, and advantages of nuclear density testing of asphalt, providing insights into its indispensable role in modern construction.

Key Takeaways

- Nuclear density testing in asphalt relies on nuclear gauges emitting gamma rays and neutrons to measure in-place density and moisture, playing a significant role in paving quality control.

- Manufacturers like Troxler, Humboldt, and InstroTek produce specialized equipment for nuclear density testing, adhering to ASTM International Standards to ensure precise and consistent measurements.

- Regulatory bodies such as the Nuclear Regulatory Commission (NRC) require rigorous safety and licensing standards for using, storing, and disposing of nuclear gauges, focusing on reducing radiation exposure risk.

The Science Behind Nuclear Density Testing of Asphalt

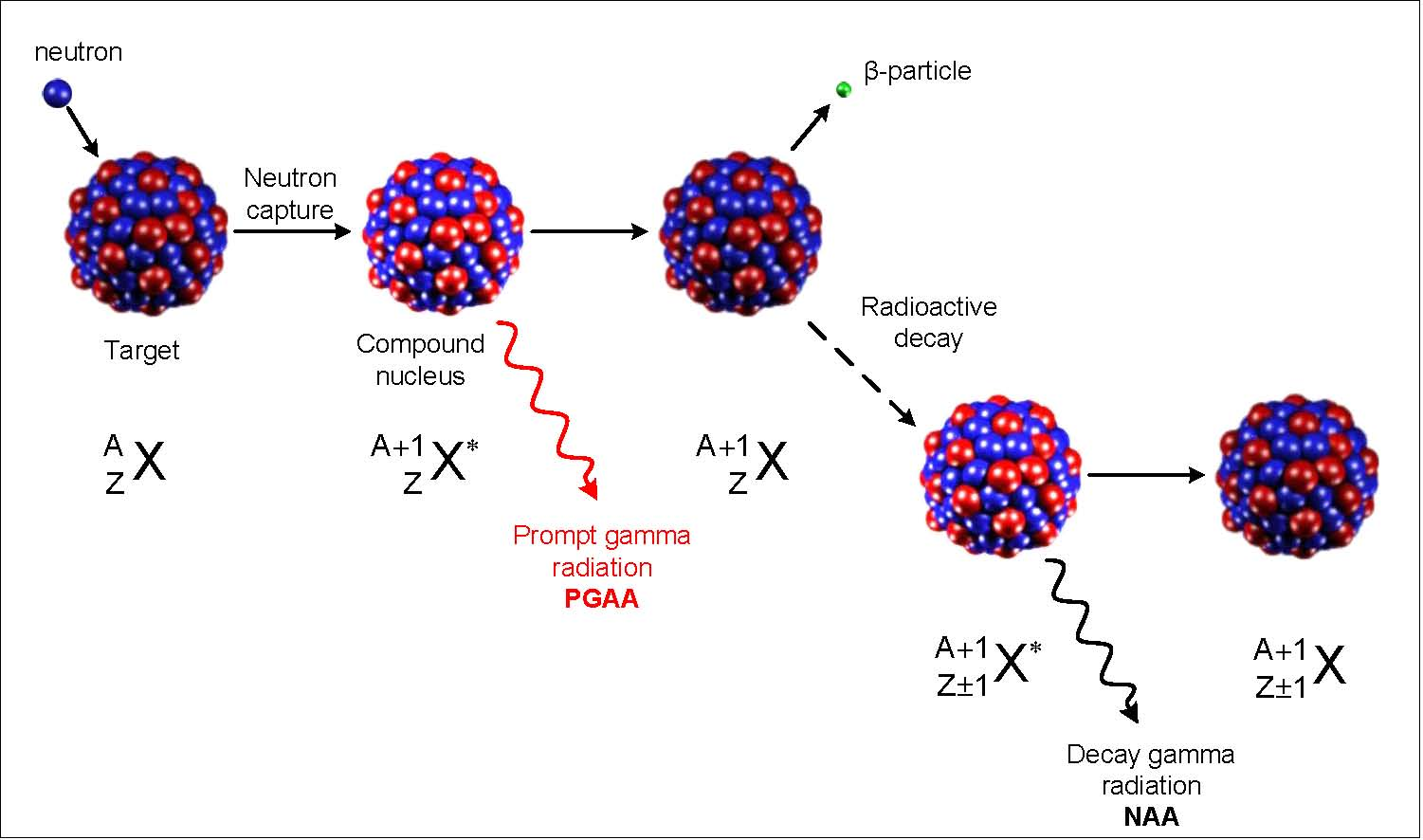

At its core, nuclear density testing of asphalt leverages scientific principles and nuclear methods to deliver accurate and reliable results. The technique uses a nuclear density gauge that emits gamma rays and neutrons, which interact with the pavement material in a specific manner.

Here’s how it works:

- Gamma rays, high-energy photons produced by radioactive atomic nuclei, penetrate the asphalt to enable precise density measurements.

- The emission of neutrons from the source scatters upon interacting with different elements within the pavement.

- The energy of the returning neutron scattering is measured and used to assess the density and composition of the material.

Beyond gamma rays and neutrons, hydrogen atoms inside the asphalt mix play a pivotal role in testing procedures. Given their abundance in water molecules, these atoms interact with the emitted neutrons to calculate water content in the test material, which is crucial in determining the wet density of the asphalt.

Keep Reading: Top Asphalt Road Testing Methods for Durability.

Gamma Rays and Neutron Sources

Gamma rays and neutron sources form the backbone of nuclear density testing of asphalt. Radioactive atomic nuclei and certain decaying subatomic particles produce these high-energy photons and subatomic particles. The emitted gamma rays penetrate materials like asphalt, providing precise density measurements at both shallow and deeper depths. Their interaction with the electrons in the pavement through absorption, Compton scattering, and the photoelectric effect is a critical part of the testing process.

In addition, a neutron source can be shielded from radiation background by using absorber material between the source and detector to enhance precision.

Hydrogen Atoms and Wet Density

The role of hydrogen atoms in nuclear density testing is of paramount importance. These atoms are identified through the use of low-level radioisotopes, which detect their presence and generate a numerical readout. The nuclear density gauge measures the density and moisture content of the material, providing valuable information for construction projects.

The interaction of hydrogen atoms with fast neutrons significantly influences the wet density. The presence of more hydrogen atoms in wetter material slows down a greater number of neutrons, which is then measured to determine the wet density. The utilization of hydrogen atoms for determining the wet density of asphalt is widely acknowledged for its accuracy and efficiency, making it a valuable tool in paving quality control.

You may also read Asphalt Compaction Testing Methods: Pavement Durability.

Equipment for Nuclear Density Testing of Asphalt

Implementing nuclear density tests requires specialized equipment. Some top manufacturers of nuclear density testing equipment include:

- Troxler Electronic Laboratories: Known for its nuclear moisture-density gauges for compaction control of soil and established nuclear technology for precise density measurements.

- Humboldt: Offers a range of nuclear density gauges and moisture meters for soil and asphalt testing.

- InstroTek: Provides nuclear density gauges and moisture meters for construction and geotechnical applications.

These manufacturers offer equipment such as nuclear densometers and moisture-density gauges, which are specifically designed to measure the density of compacted materials and the moisture content of soils, aggregates, and other materials.

Moreover, ASTM International Standards ensure precise measurements and uniformity in nuclear density testing.

Troxler Electronic Laboratories

Founded in 1958, Troxler Electronic Laboratories has been a stalwart in the development, production, and maintenance of precise quality control and measurement instruments for the construction and agricultural sectors. Their range of nuclear density testing equipment, such as the Troxler nuclear moisture density gauges, EGauge for soil density measurements, and EGauge Combo for both asphalt and soil, are known for their precision, efficiency, and exemption from conventional nuclear licensing requirements.

The company’s commitment to utilizing nuclear technology in the fabrication of their equipment, including steel rod manufacturing, ensures accurate and dependable measurements for the highway and construction sectors.

ASTM International Standards

ASTM International is a globally recognized leader in the development and delivery of voluntary consensus standards. In the realm of nuclear density testing, ASTM International develops standards that specify, test, and evaluate the materials, instruments, and techniques used in the field, thereby ensuring the consistency and accuracy of test results.

The official ASTM International standard used for conducting nuclear density testing of soil is ASTM D6938-17ae01. Adherence to these standards guarantees the precision and dependability of nuclear density test outcomes through the provision of guidelines for:

- Calibration

- Operation

- Maintenance of nuclear density gauges

- Interpretation of test results.

Testing Procedures and Calibration

Testing procedures and calibration are fundamental to nuclear density testing. The prescribed test method, outlined in ASTM D6938-17ae01, entails the measurement of in-place density and moisture of soil and soil aggregate using nuclear equipment. Calibration of the nuclear density testing equipment should be carried out at least once every 12 months to ensure accuracy and reliability. Calibration involves conducting a leak test and adhering to the instructions outlined by ASTM International.

Nonetheless, it’s imperative to avoid common errors, such as:

- solely relying on sand cone density tests for calibration

- improper positioning of the gauge

- not comparing stored standard counts to factory standard counts

- using incorrect methods to determine percent density and percent moisture.

Standard Test Method

The standard test method for nuclear density testing of asphalt, as outlined in ASTM D6938-17ae01, is a comprehensive procedure that ensures consistency and accuracy in nuclear density testing. The method involves determining the in-place density and moisture of earthwork using a nuclear moisture/density gauge.

To conduct this method, nuclear equipment is required to measure the in-place density and moisture of soil and soil aggregate. Adherence to this method ensures accuracy in nuclear density testing.

More Read: How to Test Asphalt Compaction: Mastering Pavement Quality.

Proper Calibration

Proper calibration is a crucial procedure in nuclear density testing of asphalt, ensuring the precision and dependability of test outcomes. It is recommended to calibrate nuclear density testing equipment at least once every 12 months. The calibration procedure involves conducting a leak test and adhering to the guidance provided by ASTM International.

The calibration process could be influenced by several factors, including:

- The appropriate calibration process

- The precision and dependability of the equipment

- Radiological constraints of the equipment

- The calibration factor was utilized to correlate gamma count to actual pavement density.

Safety and Licensing Requirements

Within the context of nuclear density testing of asphalt, safety and licensing requirements take precedence. Each state has an office tasked with the oversight of radioactive materials used or held within their jurisdiction. These regulations offer directives on the appropriate management and utilization of nuclear gauges, guaranteeing adherence to safety protocols and radiation standards.

Safety measures must be implemented to safeguard workers from the gamma radiation emitted by the gauges. Additionally, companies utilizing nuclear gauges are also mandated to:

- Obtain a license

- Adhere to rigorous safety standards

- Comply with regulations established by the Nuclear Regulatory Commission (NRC) for the usage, storage, and disposal of nuclear gauges.

Low-Level Radiation Exposure

Low-level radiation exposure is an inherent aspect of nuclear density testing. While it does not result in immediate health effects and is generally perceived to present a lower health risk compared to various modern lifestyle hazards, a low dose of radiation (0.001 to 0.3 Gy) can lead to a slightly increased risk over time. By using low-level radiation, nuclear density testing measures the wet density, dry density, and moisture content of soil and construction materials. This process contributes to low-level radiation exposure.

Safety precautions, such as adherence to proper operational procedures and the use of shielding, are necessary to mitigate the risks of radiation exposure during testing, ensuring sufficient energy is managed safely.

State Regulations and Licensing Programs

State regulations and licensing programs play a significant role in governing the use and maintenance of nuclear density gauges. To operate nuclear density gauges, individuals or organizations must acquire a designated license from a regulatory body, such as the Nuclear Regulatory Commission (NRC), and comply with the payment of application and annual license fees.

Specific regulations also govern the use and disposal of nuclear density gauges, ensuring their proper maintenance. Renewal of the license for operating nuclear density gauges is required on an annual basis, per regulatory guidelines.

Advantages of Nuclear Density Testing of Asphalt

Nuclear density testing presents a multitude of advantages, notably its cost-effectiveness and environmental benefits. The technique is considered cost-effective due to its efficiency, portability, and capability to measure various depths and moisture levels at the construction site. The long-term savings resulting from nuclear density testing in construction projects stem from streamlined processes that lower expenses, minimize material wastage, and promote effective construction practices.

In comparison to traditional core sampling and in situ measurements, nuclear density testing typically enhances the efficiency of the construction process. Additionally, nuclear density testing plays a critical role in ensuring the appropriate compaction of soils, thus contributing to the sustainability of construction projects. This, in turn, results in reduced pollution and waste, as precise compaction minimizes the potential for structural failure and the necessity for subsequent repairs.

Cost-Effectiveness

One of the most appealing advantages of the nuclear density testing of asphalt is its cost-effectiveness. The technique contributes to saving time and resources in pavement construction and maintenance by offering a faster alternative to conventional lab testing of extracted cores. The cost analysis indicates that nuclear density testing can indeed be more cost-effective than traditional coring methods, presenting substantial savings for the construction industry.

The estimated average cost of a nuclear density test is $400-$500 for a 10-hour day, encompassing the technician rate, travel expenses, and the daily nuclear gauge fee. In the long run, nuclear density testing enhances quality control via swift and non-destructive assessment of asphalt cement content in mixtures, resulting in higher-quality pavement that sustains integrity over time.

Environmental Benefits

Nuclear density testing of asphalt also offers significant environmental benefits. The technique minimizes waste by eliminating the necessity for strict monitoring and additional security measures that traditional methods require. In the mining industry, for instance, nuclear density measurement devices ensure optimal pumpability, leading to more efficient operations with a reduced environmental impact due to minimized waste and optimized processes.

Nuclear density testing of asphalt contributes to environmental benefits in the following ways:

- It is energy-efficient

- It provides accurate measurements of material density and moisture content

- It optimizes construction processes, leading to significant waste reductions

- It is recognized for its high capacity factor, making it an environmentally sustainable option.

Practical Applications and Case Studies

Nuclear density testing of asphalt has numerous and diverse practical applications, with its use in pavement construction and maintenance being one of the primary ones. Nuclear density testing serves the purpose of directly measuring the density and moisture content of the material being tested, thereby providing crucial information for quality control and compaction efforts.

In the realm of pavement maintenance, nuclear density testing is employed to assess in-place HMA density through the use of gamma radiation, thereby ensuring that maintenance activities are executed based on accurate measurements of the pavement’s condition. By promoting a more uniform and consistent asphalt density throughout the pavement, nuclear density testing leads to enhanced durability and longevity. Several case studies have demonstrated the effectiveness of nuclear density testing in confirming the consistency and sufficiency of pavement compaction.

Pavement Construction and Maintenance

Nuclear density testing of asphalt has revolutionized pavement construction and maintenance. By directly measuring density and moisture content, the technique provides critical information for regulating compaction efforts and verifying compliance with established specifications.

Compared to traditional methods, nuclear density testing offers substantial benefits, including:

- Non-destructive, in situ testing of wet density and moisture content

- Portability and rapid results

- Well-suited for large-scale projects where efficiency is essential for quality control

- Ensuring accurate pavement stability, particularly for thin layers of asphalt.

In the context of roadway construction, nuclear density testing is employed to ascertain the in-place density of materials, playing a crucial role in evaluating the quality and stability of the pavement being constructed.

Case Studies

The effectiveness of nuclear density testing of asphalt has been demonstrated in various real-world scenarios. The ‘Coreless Compaction Assessment’ study by the Minnesota Department of Transportation and the North Bay Case Study 2015 are noteworthy examples where nuclear density testing has proven effective in pavement construction and maintenance. Nuclear density testing has significantly improved project outcomes by enabling precise and efficient measurements crucial for quality control in construction activities. This has been evidenced in various use cases, including soil density testing by SAECO and evaluation studies conducted in field conditions.

Unconventional applications of nuclear density testing have involved the use of densometers to efficiently measure the density and moisture content of compacted soils, as well as the utilization of specialized gauges for online measurement of density and thickness in various industrial processes.

Training and Maintenance for Nuclear Density Gauges

Effective use of nuclear density gauges necessitates proper training and maintenance. The suggested training for operators consists of completing an online/internet gauge safety certification class and the initial course for individuals who need to be certified to use a portable nuclear gauge. The primary components included in operator training are radiation safety, gauge operation and maintenance, density and moisture measurement techniques, and regulatory compliance.

Regular and routine maintenance for nuclear density gauges includes:

- Cleansing the gauge with a cleaning cloth and detergent

- Scraping and cleansing the cavity where the tungsten block sits

- Substitution of routine maintenance items such as gaskets, seals, labels, and scraper ring

- Performing a comprehensive electronic system analysis

It is also recommended to calibrate nuclear density gauges every 12 months according to ASTM guidelines.

Operator Training

Operator training is a critical component of nuclear density testing. Comprehensive radiation safety programs cover gauge ownership, including exposure monitoring. They address potential risks, health effects, and dose monitoring. These programs also emphasize accurate record-keeping. The training covers specific procedures such as conducting nuclear tests for density using the Backscatter Method for asphalt materials and determining the in-place density and moisture content of soils using specific test methods. Additionally, understanding direct transmission principles is essential for accurate measurements.

Practical training conducted by the Radiation Safety Officer (RSO) or experienced gauge operator is a crucial necessity for new gauge personnel. Specific protocols exist for the correct handling and utilization of nuclear density gauges, particularly in proximity to gauges containing radioactive substances. To operate nuclear density testing equipment, operators must successfully complete a nuclear gauge safety certification class or a course that grants the essential certification.

Equipment Maintenance

Regular equipment maintenance is essential to ensure the reliability and accuracy of nuclear density gauges. The gauges should be maintained every five years, involving calibration, leak tests, and repairs to ensure their accuracy, safety, and lifespan. Regular maintenance of moving parts and refurbishment is also essential for their proper operation. Failing to maintain nuclear density gauges can risk a nuclear meltdown. It may also lead to electrical failures and inaccurate material density measurements. Additionally, it can cause heightened repair expenses due to moisture exposure.

The manufacturer specifies the components of nuclear density gauges needing regular maintenance. These include calibration and leak test systems. Moving parts may require refurbishment to ensure good operating condition.

Summary

Nuclear density testing is a revolutionary technique that has transformed quality control in asphalt construction and maintenance. Through the use of gamma rays, neutron sources, and hydrogen atoms, the method delivers accurate and reliable density measurements. Leading manufacturers like Troxler Electronic Laboratories provide essential equipment for nuclear density testing. Adhering to ASTM International Standards is crucial. This ensures consistency and precision in density testing. Strict safety and licensing requirements govern the use of nuclear density gauges, ensuring the safety of operators and the environment. Nuclear density testing is cost-effective and environmentally beneficial. Various real-world case studies show its value in pavement construction and maintenance. Adequate operator training and regular equipment maintenance are crucial for the effective use of nuclear density gauges. In summary, nuclear density testing is a powerful technique that offers significant advantages in quality control for asphalt construction and maintenance.

Certified MTP has an elite selection of Mix Marshall Design tools and equipment, showcasing industry-leading brands for Marshall Stability Test Systems, Marshall Compactor Test Equipment and Molds, Marshall Water Baths for Asphalt Testing, Asphalt Mix Design Equipment, Asphalt Pavement Testing Equipment, and Sample Ejectors for Asphalt Extrusion.

Frequently Asked Questions

What is the ASTM for nuclear density testing of asphalt?

The ASTM for nuclear density testing of asphalt is ASTM D2950/D2950M, which provides the standard test method for measuring the density of bituminous concrete in place by nuclear methods.

How to do a nuclear density test?

To perform a nuclear density test, you can follow the guidelines outlined in AASHTO T 310 for using a nuclear density gauge in field testing.

It is okay to remove the source rod from the gauge for cleaning provided to you?

No, it is not okay to remove the source rod from the gauge for cleaning unless you are an authorized user with a special license and have the manufacturer’s gauge manual present.

Are there any safety and licensing requirements for nuclear density testing?

Yes, there are strict safety and licensing requirements for nuclear density testing, including proper operational procedures, shielding to mitigate radiation risks, obtaining a license, and adhering to rigorous safety standards.

What are the advantages of nuclear density testing?

The advantages of nuclear density testing include cost-effectiveness, environmental friendliness, efficiency, portability, and the capability to measure various depths and moisture levels at construction sites. It also leads to significant long-term savings and ensures appropriate compaction of soils for sustainable construction projects.