Imagine building a skyscraper. The strength and durability of the materials used are paramount, right? One way to ensure this is through a penetration resistance test, a method that assesses the strength of construction materials, particularly concrete. This provides peace of mind that the structures will stand the test of time.

Key Takeaways

- Penetration Resistance Testing is an important tool used to evaluate the quality and durability of construction materials.

- Steel probes, testing apparatus, and statistical methods are essential for accurately measuring penetration resistance.

- Penetration tests can be customized to meet specific needs in various engineering applications such as subsea engineering.

Exploring the Basics of Penetration Resistance Testing

Construction is a complex yet intriguing field. Penetration Resistance Testing is a key tool used to ensure the longevity of our structures. This test method evaluates the quality and durability of construction materials by assessing their ability to resist penetration. The probe penetration resistance is a particularly important parameter in this process.

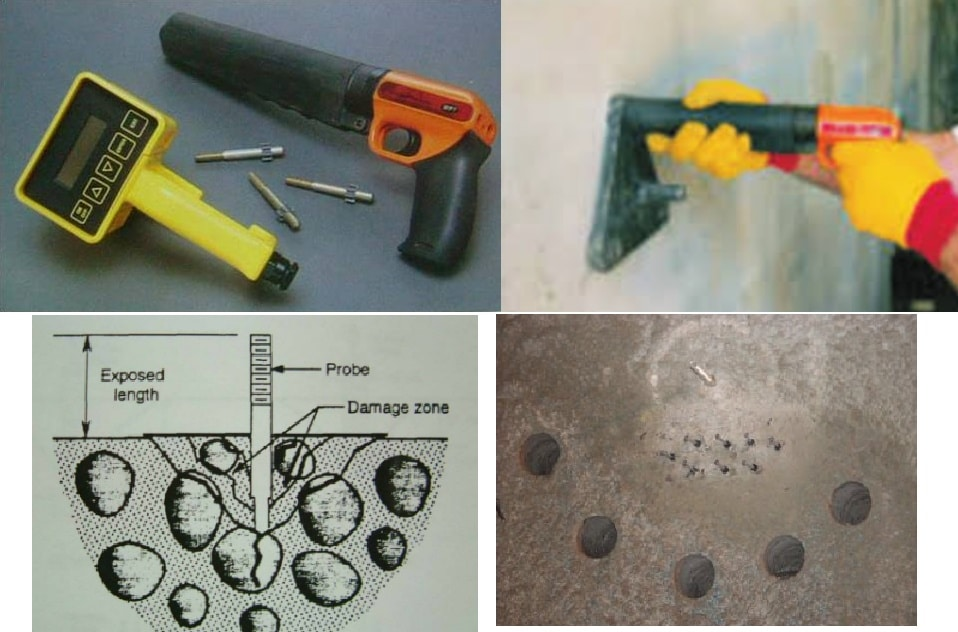

The primary objective is to assess the consistency of concrete, detect low-quality areas, and estimate the in-place strength of concrete with a specific test apparatus. The relationship between penetration and concrete strength is quite intriguing. In the Windsor Probe test, for instance, penetration is found to be inversely proportional to the strength of the concrete.

The Role of Steel Probes in Penetration Testing

Steel probes, often overlooked in penetration testing, play a significant role. These devices, typically ranging from 2mm to 10mm in diameter, are used to measure the depth of penetration into the material under test. They come in various forms such as steel probe cylinders, cones, ball probes, and needles.

and are used on formed surfaces similar to those found in construction materials.

However, shape and size aren’t the only concerns. The type of steel used also significantly impacts the results. Penetration testing probes commonly use carbon steel, stainless steel, and alloy steels. These steel forms are plated to provide corrosion protection, ensuring the accuracy and reliability of the test results.

Test Apparatus and Equipment

Reliable apparatus and equipment are the backbone of successful tests. For penetration resistance testing, Vernier calipers or depth gauges and a reference base plate are essential. These tools help accurately measure the penetration resistance of construction materials, including the influence of coarse aggregate on the test results, using the given test apparatus.

Some common tools used in material testing include:

- Vernier calipers, which provide precise measurements of the penetration depth

- Depth gauges, which measure the depth of probe penetration into the material, provide insight into the near-surface strength of the material

- A reference base plate, ensures a stable and consistent surface for testing equipment, contributing to the accuracy and reliability of test results.

Keep Reading: Understanding the Marshall Test for Asphalt Mix Design.

Methodology for Conducting the Test

Understanding the apparatus and equipment is essential. However, equally important is the comprehension of the test methodology. The process involves:

- Preparing the concrete specimen

- Inserting the steel rod

- Measuring the penetration resistance

- Recording the results

- Analyzing the data

- Interpreting the results

- Reporting the findings.

How do we position and guide the probe accurately? We securely attach the probe manipulator device to the testing equipment and use the controls to position the probe tip in the X, Y, and Z directions. Before testing, we ensure the probe is clean and free from any dirt or contamination.

We use the driver unit to apply force or pressure to the material being tested, driving the probe or pin into the concrete or soil to measure the resistance to penetration.

Assessing Concrete Strength Through Penetration Resistance

Why is penetration resistance testing so significant? The answer lies in its ability to estimate the strength of concrete by measuring the length of probes driven into the material. This test primarily assesses the on-site strength of concrete, an essential factor in deciding on early form removal or investigating low strength indications from cylinder test results.

Indeed, the penetration resistance test is known for its speed and precision in assessing concrete strength, as it provides a measure of the internal compressive strength. However, it’s important to note that various factors can impact the results of penetration resistance tests on concrete, including:

- The strength of the aggregate

- The nature of the concrete’s formed surfaces

- Moisture content

- Pore structure

- The spacing between the probes used in the testing

These factors should be taken into consideration when interpreting the results of penetration resistance tests on concrete.

Statistical Methods for Strength Correlation

ACI 228.1R, an internationally recognized standard, provides procedures and statistical methods for developing strength relationships based on penetration resistance test results. These methods involve analyzing test data to discern patterns or correlations between penetration resistance measurements and concrete strength.

Experts recommend using statistical models, including regression models and correlation testing, to establish strength relationships between penetration resistance measurements and concrete strength. Although widely acknowledged as dependable for assessing concrete strength through penetration resistance tests, this strength relationship can encounter potential accuracy and reliability issues.

Various factors, such as the nature of test conditions and the variability of the concrete material, may influence the applicability of these methods.

Factors Affecting Test Outcomes

Certain factors can substantially impact the outcomes of penetration resistance tests. For instance, the strength of the concrete has a significant influence on the results. Higher-strength concrete will demonstrate increased resistance to penetration, indicating a clear association between concrete strength and test outcomes.

The properties of coarse aggregates, such as their:

- strength

- size

- volume fraction

- angularity

The aggregate hardness can significantly affect the results. Stronger and more angular aggregates enhance penetration resistance, whereas larger and more voluminous aggregates typically decrease the resistance and penetrate more of the mixture.

The nature of the formed surface can also have a significant impact on test results. In concrete, variables such as surface strength and finish can influence the resistance observed during testing, while in soils, factors like density, composition, and moisture content play a significant role.

Distinguishing Between Similar Concrete Materials

In the detailed field of construction, even small differences can considerably affect outcomes. Penetration resistance tests can help distinguish between various types of concrete materials, including hardened concrete, high-strength concrete, and lightweight concrete, through the assessment of their relative strengths and hardness.

Moreover, these tests can detect indicators of poor quality in concrete materials, such as inadequate material strength, zones of poor quality or deteriorated concrete, loss of confidence in the measurement technique, and insufficient testing and inaccurate measurements. Once identified, these poor-quality indicators allow for standard remediation strategies, such as cement solidification/stabilization of contaminated soil, using air-entrained concrete, and addressing issues related to older design standards and poor construction practices.

Poor Quality Indicators and Remediation Strategies

Detecting low-quality concrete materials is a significant step. However, implementing effective remediation strategies is equally vital. Indicators of substandard concrete quality include low penetration resistance values, which suggest a deficiency in concrete hardness and strength. Moreover, inconsistent or uneven penetration resistance values across the concrete surface can also signify poor quality or deteriorated concrete.

Once these indicators are identified, remediation strategies come into play. These involve:

- Reducing the water-cement ratio

- Ensuring adequate compaction and curing

- Repairing or replacing deficient concrete sections

- Applying overlays or coatings to enhance surface quality.

Advanced Applications: Beyond Basic Concrete Testing

Like any scientific domain, Penetration Resistance Testing continues to evolve and broaden its scope. You can customize advanced applications of this method to meet specific construction needs, such as evaluating the durability of recycled concrete or assessing the impact resistance of polymer matrix composites.

These modifications aim to minimize the necessity for extra testing and involve additional information for measuring tip resistance to evaluate soil properties. In this way, Penetration Resistance Testing continues to prove its versatility and adaptability for a variety of construction needs.

More Reading: Test Tube Brush: Understanding Function and Uses.

Customizing Tests for Specific Construction Needs

Customization is a current demand in the construction industry. Penetration Resistance Tests can be customized to meet specific construction needs. The customization process includes:

- Identifying the specific construction requirements

- Selecting the appropriate test method

- Customizing test parameters

- Conducting the test

- Analyzing the results

- Making informed decisions based on the test outcomes.

When dealing with specialized construction materials, adjustments are made by:

- Altering the test parameters and equipment to suit the specific properties of the materials

- Using different penetration tools

- Modifying the test procedure to take into account the material’s unique characteristics.

Mortar Increments and Propellant Efficiency

Penetration Resistance Testing extends beyond concrete, playing a vital role in evaluating Mortar increments and propellant efficiency. This process aids in optimizing the formulation and composition of mortar to ensure its effectiveness in a range of construction applications.

Cone penetration tests assess mortar increments by dropping a conical plunger from a specified height into a mortar sample and measuring the depth of penetration to evaluate the mortar’s resistance. The common outcomes of these tests encompass the results of resistance-to-penetration and the expected correlation between shooting strength and propellant efficiency.

Penetration Resistance in Subsea Engineering

Penetration Resistance Testing goes beyond land-based applications, reaching into the depths of the ocean. Subsea engineering relies heavily on this testing to assess the strength and stability of construction materials utilized in subsea structures.

For instance, in the case of subsea manifolds, Penetration Resistance Testing is used to evaluate the manifold’s capacity to withstand vertical loads and prevent soil penetration. Standard procedures for conducting this testing on pipeline ends in subsea engineering include techniques like cone penetration testing (CPT) or shallow penetrometers.

Summary

The world of construction is indeed a marvel and Penetration Resistance Testing is one of its most critical tools. From evaluating the strength of concrete to differentiating between similar materials, and from assessing propellant efficiency in mortar systems to evaluating subsea structures, this method has proven to be versatile and indispensable. As we continue to push the boundaries of construction, the role of Penetration Resistance Testing will only become more vital, ensuring our structures remain strong, durable, and safe.

Certified MTP has the largest selection of NDT equipment, showcasing industry-leading brands for Ground Penetrating Radar (GPR) for Concrete, Concrete Test Hammers, Concrete Corrosion Testing for Concrete, and Concrete Crack Monitoring. For ultrasonic testing of concrete, we recommend the Proceq Pundit Lab, Ultrasonic Test Device or the Proceq Pundit Lab+ UPV Instrument.

Frequently Asked Questions

What is the penetration resistance test?

Penetration resistance testing involves inserting a probe into a material with thickness to determine its change of state or texture firmness, which is a measure of quality.

What is penetration resistance?

Penetration resistance refers to an architecture that uses a combination of technology and procedures to limit the opportunities for an adversary to breach a system, as well as a measure of a coating’s resistance to loading from soil and other buried objects.

How is the correlation between penetration and concrete strength determined?

The correlation between penetration and concrete strength is determined through the Windsor Probe test, which shows that higher penetration indicates a lower concrete strength.

Can you provide an instance of a project that effectively employed tailored penetration resistance tests?

An effective instance of a project that used tailored penetration resistance tests was the CO2-assisted polymer compression (CAPC) project. Where customized tests were crucial for material selection and development.

What is the significance of penetration resistance testing in subsea engineering?

Penetration Resistance Testing is an essential tool for engineers in subsea engineering, providing an assessment of the strength and stability of construction materials.