In today’s fast-paced, technologically advanced world, maintaining a clean and controlled environment is critical for industries ranging from pharmaceutical manufacturing to aerospace engineering. What if there was a solution flexible and cost-effective enough to meet the dynamic needs of these diverse fields? Enter the realm of Portable Clean Room, modular powerhouses designed to provide a high-quality, controlled environment, adaptable to a wide range of applications.

Key Takeaways

- Portable cleanrooms provide an economical and versatile solution for controlled environments.

- Features such as positive pressure enclosures, HEPA/ULPA filters, customizations and mobility make them suitable for various industries.

- Regular maintenance is essential to ensure sustained quality while adhering to safety standards.

Exploring Portable Cleanrooms: A Comprehensive Overview

Modular softwall cleanrooms, a type of portable cleanroom, are tent-like structures that deliver the functionality of hardwall cleanrooms at a more economical price. These lightweight enclosures offer an efficient solution for creating high-quality controlled environments, making them an increasingly popular choice among manufacturers of modular cleanrooms. They come in various dimensions, typically ranging from 4 feet by 4 feet to 24 feet by 36 feet, and can be supported by ceiling hanging points for convenience.

These versatile units find utility in a diverse range of applications and industries, including:

- Temporary cleanroom facilities

- Clean storage for on-site work in laboratories

- Medical facilities

- Electronics

- Food and beverage

- Scientific applications

Defining the Portable Cleanroom

A cleanroom is a compact, mobile system specifically designed to provide a controlled environment with clean rooms and laminar airflow. The increasing popularity of portable softwall cleanrooms can be attributed to their flexibility and cost-effectiveness. These cleanrooms come with typical features such as:

- Ceiling heights of 8, 9, or 10 feet

- Positive pressure enclosures to maintain a controlled environment and prevent contamination

- Walls made of clear, flame retardant, 40 mil thick vinyl

- Constructed from eight-inch wide, 80-mill-thick strips with a two-inch overlap, strip doors ensure a clean and controlled environment.

- They feature 99.99% efficient HEPA filters, flat panel LED lights, and clear vinyl curtains, and can also serve as negative pressure containment areas for specific applications.

Keep Reading: Top Adjustable Steel Column Choices for Sturdy Support.

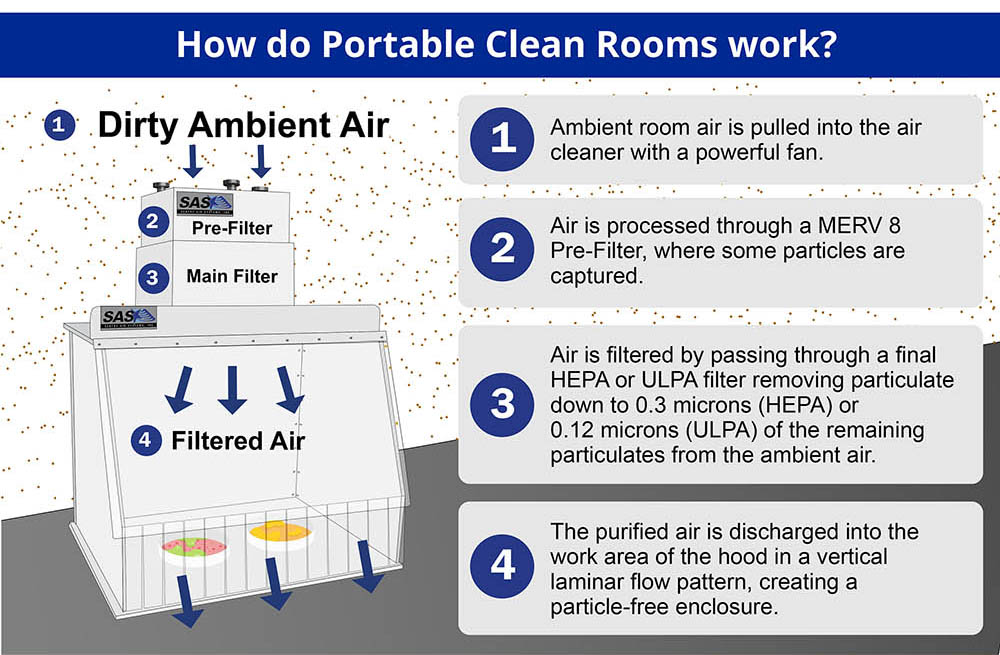

The Mechanics Behind Clean Air Control

The filters used play a crucial role in maintaining a clean environment within a portable cleanroom. HEPA or ULPA filters are commonly employed in these cleanrooms to regulate particle levels within the environment, making them an ideal choice for a portable clean room solution. One of the most effective options is the ULPA filter, which provides an even higher level of filtration compared to standard HEPA filters.

These HEPA filters are designed to capture particles as small as 0.3 microns with an impressive efficiency of 99.97%, playing a crucial role in upholding the air quality in clean rooms.

Classifications and Standards

Understanding the classification system used in cleanrooms is crucial. This system determines classifications based on particle count, and equipping portable cleanrooms with HEPA or ULPA filters ensures maintenance of the required classification and guarantees a clean environment. Depending on the specific provider, portable cleanrooms can range in classification from:

- Class 100,000 (ISO 8)

- Class 10,000 (ISO 7)

- Class 1,000 (ISO 6)

- Class 100 (ISO 5)

- Class 10 (ISO 4)

This covers a broad spectrum of requirements.

Sentry Air Systems’ portable cleanrooms, for example, have an impressive ISO 5 classification. These cleanrooms are known for their high level of cleanliness and reliability. These classifications adhere to FS 209E, a formal document that defines the standard classes of air cleanliness for cleanrooms and the clean rooms in zones.

The Advantages of Portability in Cleanrooms

In industrial applications, the portability of these cleanrooms provides numerous advantages. The mobile nature of these units allows for easy relocation and adaptability to rapidly changing industrial needs, providing increased flexibility in operations. This is particularly beneficial in industries like pharmaceutical manufacturing, where lean practices are a staple.

Another notable advantage lies in the ease of setup. Cleanrooms can be rapidly set up and broken down as compared to conventional cleanrooms. This allows businesses to adapt more effectively to evolving requirements and offers logistical benefits such as adaptability, scalability, and cost-effectiveness throughout the installation and utilization process.

Mobility on the Move

Portable cleanrooms have an advantage in dynamic work environments due to their mobility. Their capacity for easy transport and quick setup at various locations allows for their immediate use and minimizes downtime, making them well-suited for industries with rapidly shifting conditions and requirements. Portable cleanrooms operate efficiently, and their performance typically remains unaffected during relocation. The modular design allows the cleanroom to maintain functionality even after disassembly, movement, and reassembly in a new location.

With sizes ranging from 12 feet by 12 feet to the maximum size of a whopping 440 square feet of manufacturing space, and weights varying from as little as 11 lbs to as much as 35,000 lbs, these units cater to customers with a wide spectrum of needs.

Quick Setup and Breakdown

Setting up a cleanroom is a relatively quick and straightforward process, usually requiring only one person and no special tools or equipment. The duration can vary from a few days to a few weeks, depending on the size and complexity of the cleanroom. This ease of assembly and disassembly facilitates management of the setup and breakdown process, even by individuals without expertise. However, it’s worth noting that the process may vary depending on the size or classification of the cleanroom, as these factors determine the necessary standards for airborne particle levels.

Construction and Customization Options for Cleanrooms

A variety of construction and customization options are available with cleanrooms to accommodate a range of applications. The main structural component utilized in their modular design is the ceiling grid framework, which consists of:

- Tubular steel beams with T-bar cross members

- Tubular steel legs to support the ceiling at each corner, further reinforced with heavy-gauge, triangular steel gussets

- Powered HEPA filter units, lighting systems, and ceiling panels that are all sealed to the grid using gasket material

This ensures a secure and airtight fit.

The design and construction of these cleanrooms commonly use high-quality materials like epoxy resin or PVC for the floors, sheetrock, acrylic panels, or aluminum insulated panels for the walls, and HEPA or ULPA filters for air filtration.

More Reading: Top 10 lbs Sledge Hammer Choices for Construction Projects.

Materials and Manufacturing Quality

The effectiveness of cleanrooms is directly influenced by the quality of materials used in their construction. High-quality materials are crucial for maintaining a controlled environment with minimal contamination, which is essential for safeguarding manufacturing processes and the quality of finished products. The manufacturing process typically involves:

- Designing

- Manufacturing components offsite

- Delivering these components to the construction site

- Assembling 100% prefabricated panels that meet company specifications

Adherence to manufacturing quality standards, like ISO 14644-1:2015, offers essential guidelines and requirements for particle-controlled environments, ensuring that cleanrooms comply with cleanliness standards.

Clear indicators of high-quality manufacturing include:

- Adherence to ISO ratings

- Consistent repeatability

- Application-specific compliance

- Meticulous consideration of product characteristics during the manufacturing process.

Tailoring to Specific Applications

Customizable to meet the distinct requirements of various industries and applications, portable cleanrooms offer a flexible solution. For instance, the pharmaceutical industry tailors cleanrooms to establish environments specific to their processes and requirements. The electronics industry customizes cleanrooms to meet the specific requirements of semiconductor manufacturing.

In a hospital setting, cleanrooms may require components like air showers, walls and partitions, modular wall panels, and airflow monitoring systems. Even in the biotech and nanotechnology sectors, cleanrooms can be customized with features like touch-screen environmental control systems, alarms, and remote diagnostics.

Implementing Portable Cleanrooms Across Industries

A wide range of industries utilizes cleanrooms. Their flexibility and ability to maintain a controlled environment make them an invaluable asset in diverse fields, including:

- Food production

- Semiconductor manufacturing

- Pharmaceutical industry

- Biotechnology

- Medical device production

- Life sciences

The applications of portable cleanrooms in the pharmaceutical industry are varied and encompass areas such as semiconductor manufacturing, biotechnology, medical device production, and life sciences.

In the electronics industry, portable cleanrooms help uphold a high standard of contamination control, crucial for microelectronics manufacturing and ensuring product quality and consistency. They also play a pivotal role in scientific research, providing controlled environments necessary for conducting experiments and analysis without the risk of contamination.

Use Cases in Various Fields

Portable cleanrooms offer significant benefits to the pharmaceutical industry. They are instrumental in providing a contaminant-free environment crucial for biotechnology research and drug manufacturing, thereby ensuring product integrity.

Similarly, in the electronics industry, portable cleanrooms provide a contaminant-free manufacturing space crucial for producing sensitive electronic components such as microprocessors, thereby improving product quality and reliability.

In the aerospace industry too, portable cleanrooms are indispensable. They safeguard a contaminant-free environment for the precise manufacturing and assembly of aerospace components, thereby ensuring the safety and functionality of parts and equipment.

Compliance and Regulatory Considerations

The implementation of cleanrooms necessitates consideration of various compliance and regulatory factors. Key regulatory entities for cleanrooms globally include:

- International Organization for Standardization (ISO)

- Food and Drug Administration (FDA)

- European Medicines Agency (EMA)

- Occupational Safety and Health Administration (OSHA)

In the pharmaceutical sector, the primary regulatory standards governing portable cleanrooms encompass Good Manufacturing Practices (GMP) and ISO 14644-1.

For the electronics industry, portable cleanrooms typically need to be constructed to comply with ISO Class 5 cleanroom standards. In the aerospace sector, regulatory compliance plays a crucial role in ensuring that portable cleanrooms adhere to essential standards and regulations. In medical manufacturing, portable cleanrooms must conform to ISO 14644-1 classification system to ensure adherence to cleanliness requirements.

Selecting the Right Portable Cleanroom Provider

Choosing an appropriate cleanroom provider requires thoughtful evaluation of various factors. You need to evaluate the provider’s experience, customer reviews, certifications, customization options, and technical expertise and support services to ensure they can meet your specific needs. It’s equally important to consider the quality of the materials used, manufacturing processes, lead time, flexibility, customization options, and overall cost to ensure you’re getting a high-quality product that aligns with your specific requirements. A reputable portable cleanroom provider should offer comprehensive customer support, including installation, maintenance, troubleshooting, repairs, and training.

Criteria for Evaluating Providers

The reputation of a portable cleanroom provider is a significant factor to consider when making a selection. A reputable provider should:

- Offer high-quality cleanrooms that adhere to industry standards and deliver reliable performance

- Offer a diverse range of product offerings, including composite repair cleanrooms and industrial mobile cleanrooms

- Offer customization options, including size and configuration variations, a range of clean grades, and the option to select design finishes.

This adaptability ensures that the cleanroom can adeptly address and match the distinct needs of various industries and applications.

Contacting Experts for Consultation

Consultation with experts who can offer customized guidance is vital before purchasing a portable cleanroom. Experts evaluate your space, ensure adherence to industry regulations, and suggest suitable cleanroom solutions, ultimately reducing the risk of contamination and improving operational safety and efficiency.

To locate and contact a reputable specialist for consultation on cleanrooms, consider contacting companies that provide cleanroom consulting services, such as:

- Cleanetics

- Clean Air Technology

- Cleanroom Design LLC

- Mecart Cleanrooms

Their credibility can be assessed by considering factors such as experience, qualifications, reputation, industry knowledge, and references.

When consulting with a cleanroom provider, inquire about the following:

- Types of portable cleanrooms they offer

- Sizing and configuration options

- Construction materials

- Achievable cleanliness levels

- Installation and setup services

- Customization capabilities

- Maintenance needs

- Available additional features

- Lead times

- Warranty support

Maximizing Your Portable Cleanroom’s Potential

Adherence to a regular cleaning and serving schedule is vital for maximizing the utility of your cleanroom. Consistent commitment to daily and weekly tasks is necessary for optimal performance. Regular inspection and replacement of the HEPA filters every three years is also crucial to maintain their proper functionality.

Guides and manuals for maintaining portable cleanrooms are readily accessible and should be referred to for comprehensive instructions on ensuring the optimal performance of your cleanroom unit.

Maintenance Tips for Sustained Quality

Regular maintenance is critical to maintaining the quality of portable cleanrooms. Here are some key tasks to include in your cleaning schedule:

- Regular vacuuming

- Wiping surfaces with specialized cleanroom wipes

- Establishing daily maintenance routines to effectively eliminate contaminants and uphold cleanliness

- Biannual HVAC system maintenance

When it comes to cleaning, it’s essential to utilize detergents that can efficiently break down dirt without causing corrosion or shedding particles.

Disregarding the upkeep of a cleanroom can lead to:

- Surface deterioration

- Diminished effectiveness

- Heightened contamination risks

- Safety hazards

- Challenges with compliance and liability

It’s also important to note that there are distinct maintenance procedures designed for different types of portable cleanrooms.

Operating Procedures to Maintain Cleanliness

Maintaining cleanliness and control within the cleanroom environment necessitates proper operating procedures. These procedures involve adhering to a specific cleanroom cleaning procedure to manage contamination, regularly cleaning equipment, inspecting for rust or chips, and obtaining authorization for any chemicals or materials introduced into the cleanroom. To reduce contamination, we recommend following a strict gowning protocol, limiting personnel presence, promoting good personal hygiene, using air-locks and airflow systems, and executing thorough cleaning and disinfection procedures. Additionally, establishing clean and dirty areas within the cleanroom can further control contaminants.

Cleaning procedures should be conducted daily, encompassing tasks such as vacuuming ceilings and walls, washing windows and pass-throughs, and scrubbing all surfaces, floors, and walls with deionized water. Effective operation of a portable cleanroom requires all room operators to undergo thorough training, encompassing efficient cleaning techniques, maintenance of cleanliness within the cleanroom, and strict adherence to proper operating procedures.

Summary

In conclusion, cleanrooms offer a flexible, cost-effective solution for maintaining controlled environments across diverse industries. From their modular design and quick setup to their customization options and high-quality materials, these cleanrooms are engineered to meet specific requirements and uphold industry standards. With the right provider and maintenance routines, you can maximize the potential of your portable cleanroom and ensure its longevity and effectiveness. As the world continues to evolve, so does the need for adaptable, efficient solutions like portable cleanrooms.

Frequently Asked Questions

How much does cleanroom space cost?

The average cost of a 10′ by 10′ cleanroom space is estimated to be between $10,000 and $15,000.

What is a clean room also called?

Cleanrooms, also known as modular cleanrooms, are cost-effective solutions for the protection of sensitive processes from environmental contaminants. These cleanrooms are designed to meet specific ISO and Federal STD standards.

What are the two types of clean rooms?

The two most common types of clean rooms are modular manufactured cleanrooms and stick-built (or standard) cleanrooms.

How do I turn my room into a clean room?

Start by taking out all the trash, picking up dirty clothes, and putting away clean clothes. Strip your bed and clear surface clutter, wiping down surfaces and dusting curtains, light fixtures and ceiling fan blades. Make it into a game by playing music, writing a list, and giving yourself rewards to keep yourself motivated. You’ll have a sparkling clean room in no time!

What is a clean room cleaner?

A clean room cleaner is a device that removes pollutants, particles, and contaminants from ambient air by passing it through a filter system such as HEPA or ULPA. This ensures a controlled environment with safe and decontaminated air.