Selecting the right tamping rod is crucial for the precision of concrete tests. This tool, typically sized at 12 x 3/8 inches and crafted from stainless steel, is central to slump and unit weight tests, ensuring your concrete meets quality standards. In this guide, we examine how tamping rod specifications and materials affect testing, and provide practical advice for choosing and caring for your consolidation rod to extend its utility on the job site.

Key Takeaways

- Tamping cylinder rods are essential tools in concrete testing, with the standard dimension being 12 x 3/8 inches and stainless steel being the preferred material for its durability and rust resistance.

- The proper use of tamping rods, as per ASTM and AASHTO standards, is vital for accurate concrete testing results in applications such as slump tests and unit weight tests.

- Selecting the right rod involves considering the length and diameter appropriate for the testing application, as well as ensuring the rod’s compliance with industry standards and its maintenance for ongoing reliability.

Tamping Rod: A Comprehensive Guide

If you’ve ever witnessed a concrete testing procedure, you’ve likely seen a tamping cylinder rod in action. These cylindrical straight steel rods are used in conjunction with concrete cylinder molds, slump cones, and unit weight tests, playing a pivotal role in determining the properties of fresh concrete. How do tamping rods differ from one another? The answer lies in their dimensions and the material they’re made from.

In the world of concrete testing, the popular choice for a rod is a 12 x 3/8 inch size. This size is versatile, meeting multiple testing requirements and making it a handy tool in large quantities. As for the material, stainless steel is predominantly used, thanks to its exceptional durability and resistance to rust, ensuring that your tamping rod remains reliable over time.

Dimensions: 12 x 3/8in

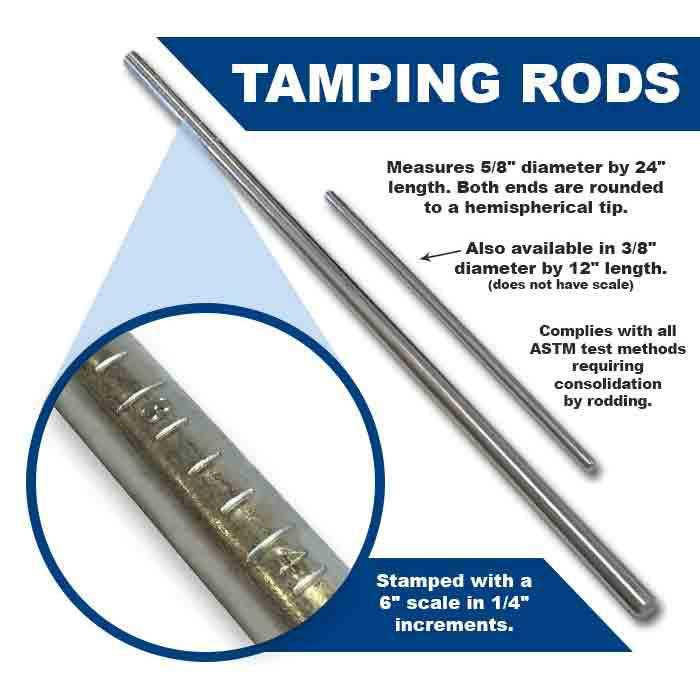

The 12 x 3/8in dimension of a tamping rod, indicating that it is 12 inches long and 3/8 inches in diameter, is a popular choice due to its versatility. It is widely employed for consolidating fresh concrete in a variety of testing applications, making it a go-to choice for professionals in the field. This size is appropriate for use with concrete cylinder molds, slump cones, and unit weight tests, facilitating the execution of slump, air content, and strength tests of fresh concrete.

What makes this size so versatile and popular? The answer lies in its ability to meet the requirements of different concrete testing applications. By providing a balance between length and diameter, the 12 x 3/8in tamping concrete rod ensures efficient and thorough compaction of fresh concrete, helping achieve precise test results.

Materials and Durability: Steel and Rust Resistance

As for the material of tamping concrete rods, stainless steel remains the top choice. Known for its high tensile strength and notable enhancement in hardness, a straight steel rod is a superior choice over other prevalent materials like aluminum. It provides the durability required for the demanding task of concrete testing and ensures an extended lifespan.

However, the advantages of steel extend beyond durability. One of the key features of stainless steel is its rust resistance. This is critical as it prevents rust resistance and corrosion, which could undermine the structural strength of the straight steel rod. With rust resistance, you can ensure the longevity of your tamping rod, maintaining its dependability in various concrete testing scenarios.

Tamping Rod: The Role in Concrete Testing

Now that we understand what tamping straight steel rods are and their composition, let’s explore their role in concrete testing. Contractors use tamping rods to consolidate fresh concrete samples for slump, air content, and strength tests, adhering to ASTM and AASHTO standards. Whether conducting a slump or unit weight test, tamping rods uniformly compact the concrete, eliminating voids, and yielding dependable, precise results.

Understanding the role of tamping straight steel rods in concrete testing is not complete without discussing the regulations that oversee their use. These regulations include:

- ASTM C143

- ASTM C31/31M

- ASTM C138/C138M

- AASHTO T 119

- AASHTO M 205

- AASHTO T 152

Provide guidelines on how to use tamping straight steel rods to achieve accurate and reproducible test results with plated rods.

Slump Tests: Slump Cones and Rods

One of the key applications of tamping rods is in slump tests. These tests are used to measure the consistency and workability of freshly made concrete before it sets, helping determine the appropriate water content in a batch of concrete. Tamping straight steel rods are used in these tests to eradicate air voids in concrete, contributing to the accuracy of the test results.

The role of a tamping straight steel rod in a slump test is not limited to removing air voids. The 6’’ scale on the end of the tamping rod also serves to measure the slump of the concrete following the completion of the test. This dual functionality makes tamping straight steel rods an indispensable tool in slump tests, ensuring both the uniformity of the concrete mix and the accuracy of the test results.

Unit Weight Tests: Measuring Fresh Concrete

Another crucial application of tamping straight steel rods is in unit weight tests. In these tests, They are used to uniformly distribute and compact fresh concrete specimens by rodding each layer 25 times, thereby eliminating voids to ensure dependable and precise test results.

Unit weight tests of fresh concrete are of significant importance in construction projects. They help determine the self-weight of the material, ensure quality control, confirm adherence to the approved mix design, and calculate concrete yield and relative yield. All these factors play a vital role in the successful execution of a project. Therefore, the role of tamping concrete rods in unit weight tests is crucial and cannot be overlooked.

Key Features of High-Quality Rods

What distinguishes high-quality tamping rods from the rest? Is it just about the size and material, or is there more to it? The answer is, indeed, there’s more. High-quality tamping rods are characterized by specific features, including hemispherical tips, rounded ends, and compliance with ASTM and AASHTO standards.

These features provide numerous benefits when used with concrete cylinder molds, slump cones, and unit weight measures. For instance, the rounded tips facilitate easier and more efficient tamping of the concrete cylinder molds, minimizing the formation of scale and ensuring precise test results. Meanwhile, the presence of rounded ends on a tamping concrete rod contributes to the attainment of consistent results in concrete tests, such as the slump test.

Moreover, adhering to ASTM and AASHTO standards guarantees that the rods fulfill the criteria for evaluating the workability of fresh concrete and other crucial concrete properties.

Hemispherical Tips and Rounded Ends

The use of hemispherical ends on tamping concrete rods in concrete testing offers several benefits:

- They provide a smooth and rounded surface for tamping the concrete sample, ensuring uniform compaction.

- They minimize the likelihood of air voids or irregularities in the test results.

- They are a preferred choice for professionals in the field.

In addition to hemispherical tips, high-quality tamping rods also feature rounded ends. These rounded ends ensure uniform compaction of concrete and prevent damage to the testing surface, contributing to the accuracy and consistency of the test results. With these features, tamping rods can ensure the proper consolidation of concrete, leading to reliable test results.

Compliance with ASTM and AASHTO Standards

Compliance with ASTM and AASHTO standards is another key feature of high-quality tamping rods. These standards provide guidelines and specifications for the construction and dimensions of tamping concrete rods, guaranteeing that they adhere to the necessary standards for accuracy and consistency in concrete testing.

Failure to comply with these standards may lead to erroneous test outcomes or inappropriate handling of the concrete. Therefore, when choosing a tamping rod, it is crucial to ensure that it complies with the specifications outlined in ASTM C143 and AASHTO T 119 standards. This will confirm its suitability for concrete testing purposes and guarantee precise and dependable testing of the workability of fresh concrete.

How to Choose the Right Rod for Your Needs

The process of choosing the right tamping concrete rod involves careful consideration of several factors:

- Length and diameter of the rod

- Price and quality

- Type of soil or material being compacted

- Depth of the mold in which rodding is being done

These factors will help determine the most suitable tamping rod for your needs.

The right length and diameter of a tamping concrete rod can significantly affect its efficacy in compacting concrete specimens during testing. Therefore, it is imperative to select a rod of a size that aligns with the dimensions and depth of the concrete specimen.

Moreover, when assessing the pricing of tamping rods, it is important to consider factors such as the rod’s diameter and length, the quality of the material, and whether it complies with ASTM standards, as well as the quantity of rods being purchased.

Determining the Appropriate Length and Diameter

When it comes to determining the appropriate length and diameter of a tamping rod, there are a few factors to consider. These include the type of soil or material being compacted, as well as the specific concrete testing method, such as slump testing or cylinder mold testing.

Typically, the suitable length of a tamping graduated steel rod should be a minimum length of 100 mm (4 inches) and should surpass the depth of the mold by at least 4 inches during rodding. As for the diameter, the standard measure is generally 5/8 inch (16 mm).

It’s standard practice to use a tamping graduated steel rod with a diameter three times the coarse aggregate’s maximum nominal size and a length-to-diameter ratio of 2:1 for the cylinders being plated and tested.

Comparing Prices and Quality

When comparing prices and quality of tamping rods, it’s important to note and remember that:

- The highest price doesn’t always equate to the best quality.

- The price of tamping rods can vary depending on the quality and additional features.

- It’s also possible to find high-quality compaction rods at affordable prices.

Contributing factors to the quality of tamping graduated steel rods encompass the suitable length and diameter for the application, the type of material being compacted, and the design advancements that guarantee lightweight and durable rods. By understanding these factors and comparing prices across different brands and models, you can ensure that you’re getting the best value for your money.

Proper Care and Maintenance of Rods

Ensuring the longevity and performance of your rods necessitates proper care and maintenance. This includes cleaning them after each use and storing them in a dry and clean environment to prevent rust and damage.

However, the scope of proper care and maintenance goes beyond cleaning and storage. Regular inspection for signs of wear and tear, such as cracks, chips, or dents, is crucial for maintaining tamping rods in optimal condition. By taking good care of your tamping graduated steel rods you can ensure their reliability and accuracy in concrete testing.

Cleaning and Storage

Cleaning tamping steel rods meticulously after each use is crucial. This includes wiping the piston of the tamping rod with a swirl motion and performing regular inspection and cleaning to uphold performance. For steel compaction rods, it’s advisable to use mild soap or a dedicated cleaning solution containing alkaline, alkaline chlorinated, or non-chloride chemicals to ensure the material is maintained without causing damage.

Storage is equally crucial to prolong the lifespan of your tamping steel rods. They should be stored in a clean and dry area to prevent corrosion or degradation, thereby preserving their optimal performance and extending their lifespan.

Inspecting for Damage and Wear

To keep your tamping cylinder rods in optimal condition, regular inspections are essential. Look for signs of damage, including cracks, chips, or wear and tear. Any worn-out parts, such as belts, should be replaced as necessary to ensure safety and optimal performance.

The presence of cracks or chips in the rod can compromise the accuracy and consistency of concrete testing. This can lead to uneven compaction of the concrete, resulting in variations in the measured slump or compressive strength. It is crucial to maintain the tamping rod in good condition to ensure reliable and accurate test results.

Related Blogs and Resources

Numerous blogs and other resources are available to deepen your understanding of tamping cylinder rods and their applications in concrete testing. These sources can provide additional information, practical tips, and expert insights that can help you get the most out of your rods.

Blog Post Recommendations

Several authoritative blogs provide in-depth insights into the world of tamping rods. Some highly recommended ones include:

- ‘Tampering Rod for Concrete Slump and Cylinder Mold Tests,’ which explores prominent models such as the Marshall Tamping

- ‘Fence Post Tamper,’ discussing the use of a grounding rod for packing gravel

- ‘A Lighter Tamper,’ explaining a specific tamper design

- ‘A Quick Guide to Tamping Coffee,’ which addresses the technique of tamping coffee for baristas.

These blogs offer valuable insights and practical tips, making them a great resource for both beginners and seasoned professionals.

Additional Resources

Additional resources, valuable for those who want to explore the subject further, are also available. Professional forums and discussion boards like the Structural Engineering General Discussion Forum, Engineer Boards Forum, and Fine Homebuilding Forum offer insights and advice on tamping rods and concrete testing.

Besides, the instructional videos accessible online, such as the ASTM C31 – Making and Curing Concrete Test Specimens in the Field, offer visual guidance on the utilization and upkeep of tamping rods.

Summary

In conclusion, tamping rods play a crucial role in concrete testing. Their design, dimensions, and material, along with compliance with ASTM and AASHTO standards, set high-quality tamping rods apart. Choosing the right tamping rod involves careful consideration of factors like length, diameter, price, and quality. Proper care and maintenance, including cleaning, storage, and regular inspection, are essential for their longevity and performance. With the wealth of information available in related blogs and resources, you can further your knowledge and make the most out of your consolidation rod in concrete testing.

Certified MTP has the largest selection of concrete testing supplies, showcasing industry-leading brands for Concrete Air Entrainment Meters, slump testers, Concrete Test Cylinder Molds, and fresh concrete testing equipment. We also offer the largest selection of tamping rods for concrete tests.

Frequently Asked Questions

What is a rod for concrete tamping used for?

A rod for concrete tamping is used to eliminate air voids in concrete during slump tests, concrete cylinder making, or conducting concrete air entrainment tests. It is round, hemispherically rounded on both ends and plated for corrosion resistance.

What size is a cylinder tamping rod?

A tamping cylinder rod comes in diameters of 5/8 or 3/8 inches and rod lengths of 12, 18, or 24 inches. Choose the size that best suits your needs.

Is tamping concrete necessary?

Tamping concrete might be unnecessary due to modern mixes with specific admixtures. Always verify with the supplier for exact requirements. If compacting is required, tools such as a tamping beam or roller tamp can be used.

Why is stainless steel predominantly used as the primary material in the fabrication of tamping cylinder rods?

Stainless steel is predominantly used for tamping rods because of its exceptional durability and resistance to rust, ensuring long-lasting performance.

How can I choose the right tamping cylinder rod for my needs?

Consider the rod’s length and diameter, compare prices and quality, and ensure it meets ASTM and AASHTO standards for an informed choice.

Related Blogs for Tamping Cylinder Rod:

Uncovering the Best Slump Cone: A Comprehensive Guide

Understanding the Slump Tester & Its Uses

Slump Test of Concrete: A Comprehensive Guide

Slump Test Table: Measure Workability of Concrete

Tampering Rod for Concrete Slump and Cylinder Mold Tests

Slump Test: Measuring the Consistency of Fresh Concrete

Concrete Slump: What Is It and Why Does it Matter?

Finding the Workability of Concrete with the Slump Test

How to Perform a Slump Test of Concrete: Steps and Results

Consistency of Concrete; How It’s Measured, Why It’s Important, and Relation to Workability

The Proper Pressure with Certified Concrete Testing Products

Materials Testing Experts Explain The Importance Of Concrete Testing

Mastering K Tester: Accurate Concrete Slump Measurements