Drying ovens have become an indispensable tool in various industries and laboratories, thanks to their versatility and ability to maintain precise temperature control. Whether used for food preservation, electronics manufacturing, or pharmaceutical sterilization, these high-performance industrial drying ovens and devices ensure consistent, reliable results. In this blog post, we’ll dive into the world of drying ovens, exploring their different types, key features, and the wide range of applications they serve. Get ready to discover how these essential drying oven solutions can help you achieve the perfect drying solution for your specific needs.

Key Takeaways

- Ovens for drying are used for a variety of industrial and laboratory needs, distinguished by their heating mechanisms.

- Key features to consider when selecting an oven for drying include temperature uniformity, precise temperature control, and energy efficiency.

- Maintenance tips such as regular cleaning and calibration checks should be followed to ensure optimal performance of the oven for drying.

Understanding Drying Ovens

Dry ovens have a wide range of usage. This includes the simple tasks of drying and sterilizing glassware as well as more intricate processes such as bonding and curing that require accurate temperature control. With drying ovens’ heating and drying capabilities, various types are available, such as convection, vacuum, and conveyor drying furnaces, catering to the unique demands of industrial and laboratory applications.

We’ll further explore these types, emphasizing the differences in their heating mechanisms and applications.

Convection Ovens

Convection dry ovens utilize either natural or forced air circulation to achieve uniform temperature distribution, ensuring efficient drying processes. Mechanical convection ovens, for instance, incorporate an integrated fan to circulate air within the chamber, resulting in even temperature distribution and making them suitable for industrial drying applications.

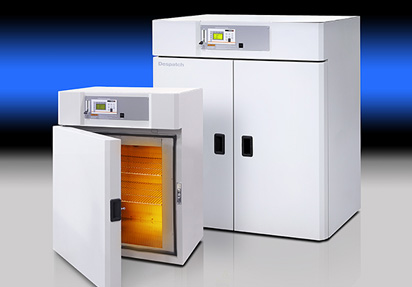

One prime example is the Despatch LBB Forced Convection Benchtop Oven, a cost-effective solution that combines horizontal and vertical airflow to provide excellent temperature uniformity. As a result, mechanical convection ovens offer optimal temperature uniformity for reproducible results and quicker drying compared to gravity convection, making them an efficient choice for valuable benchtop space.

Vacuum Drying Ovens

When it comes to dealing with delicate materials, vacuum drying ovens have the edge. These specialized ovens use low-pressure environments for heating, minimizing oxidation and preventing contamination. Using low-pressure atmospheres, vacuum drying ovens allow for quicker and gentler drying than traditional ovens, fitting compact heating applications well.

Industries such as food processing, electronics manufacturing, and pharmaceuticals often rely on vacuum drying ovens for processes that require controlled heating. In laboratories, vacuum drying ovens come in handy for various purposes, including:

- Glassware drying

- Dry sterilization

- Aging tests

- Material testing

In these applications, simultaneous heating ensures uniform heating, which is essential for accurate results across multiple applications.

Conveyor Drying Furnaces

For mass production of small or medium-sized products without high performance ovens, conveyor drying furnaces are the go-to option. These ovens facilitate continuous production by manufacturers, thanks to their conveyor belt design. The Despatch PC Series Conveyor Oven, for instance, features a continuous belt design that streamlines the drying process.

Such furnaces provide an efficient and fast drying solution for industries that need to process large quantities of products.

Types of Drying Ovens

In addition to the types mentioned above, there are other ovens for drying available for various applications, such as:

- Rotary drying ovens: designed to efficiently and uniformly dry materials, using a rotating drum for even heat and air circulation

- Gravity convection ovens: rely on natural convection to circulate air and heat within the oven

- Forced air convection ovens: use a fan to circulate heated air throughout the oven

These different types of ovens that have drying offer flexibility and efficiency for different drying needs.

Vacuum drying ovens, on the other hand, utilize a vacuum chamber for efficient moisture removal, resulting in quicker drying times and more accurate temperature control.

Next, we’ll further examine the differences between gravity convection, a mechanical convection oven, and forced air ovens.

Gravity Convection Ovens

Gravity convection ovens are a great choice for delicate materials, as they rely on natural air circulation for efficient drying and controlled heating throughout. These ovens operate using the natural process of convection, where hot air rises and cold air sinks, creating their own internal airflow without the need for a fan or other air circulation mechanism.

Their gentle drying and heating capabilities, energy efficiency, and low maintenance requirements make gravity convection ovens suitable for industries such as food processing, electronics manufacturing, and pharmaceuticals, as well as laboratory applications like glassware drying, dry sterilization, and aging tests and material testing.

Mechanical Convection Ovens

Mechanical convection ovens are equipped with fans to circulate hot air throughout the dry heat ovens’ chamber, providing even temperature distribution and faster drying times. This uniform temperature distribution makes them an optimal choice for industrial purposes, ensuring accurate and consistent drying results.

Key considerations when choosing a mechanical convection oven include temperature uniformity, precise temperature control, and energy efficiency.

Forced Air Ovens

For rapid and uniform drying, forced air ovens shine. Its combine high-performance heating elements with powerful fans to circulate hot air rapidly throughout the interior. As a result, forced air ovens offer the advantages of faster drying times and more uniform temperature distribution, making them ideal heating parts for various industrial applications, such as food processing, electronics manufacturing, and the pharmaceutical industry.

Forced air ovens are also highly efficient, as they require less energy to heat up and

Key Features to Look For in an Oven that Dries

Choosing an oven that dries requires careful consideration of key performance and efficiency features. Important factors to keep in mind include temperature uniformity, precise temperature control, and energy efficiency.

Subsequently, we’ll detail each of these features, underscoring their role in producing dependable and consistent drying outcomes.

Temperature Uniformity

Maintaining steady temperatures throughout the oven chamber is imperative for dependable drying outcomes. Temperature uniformity can be achieved by employing fans and heating elements that evenly distribute heat throughout the oven chamber, guaranteeing that the temperature remains consistent and leading to dependable and consistent drying results.

Furthermore, temperature uniformity helps minimize the risk of product damage due to uneven heating, making it an essential factor to consider when using drying samples and selecting a dehydrator.

Precise Temperature Control

Precise temperature settings are crucial to attain ideal dehydrator conditions and prevent harm to sensitive materials. A drying oven with programmable controls and a digital display can be used to achieve precise temperature control, ensuring that your drying process operates within the desired temperature range.

Moreover, implementing additional features such as a stainless steel interior, an extra layer of insulation, and calibration checks can help to ensure precise temperature control.

Low Energy Consumption

Ovens with high energy efficiency offer several benefits:

- They cut down operating expenses

- They lessen environmental impact by consuming less energy

- They contribute to a decrease in the amount of greenhouse gases released into the atmosphere

This highlights the importance of selecting energy-efficient appliances.

Strategies to reduce energy consumption may include utilizing energy-efficient appliances, implementing insulation and weatherization measures, and developing energy-saving habits.

Industrial Applications of Ovens For Drying Conditions

Ovens are utilized in a broad spectrum of industrial applications, spanning incubation, sterilization, evaporation, and paint dehydrator. Next, we’ll examine the use of oven drying in diverse industries such as food processing, electronics manufacturing, and pharmaceuticals, highlighting the versatility and significance of these devices in delivering consistent, reliable results.

Food processing is one of the most common applications for ovens for dehydrator. They are used for baking anything to dry

Food Processing

In the food processing industry, drying ovens play a crucial role in the dehydration and preservation of food products, guaranteeing consistent quality and prolonged shelf life. By maintaining precise temperature control, ovens dry to ensure the safety and excellence of food products, making them an essential piece of equipment in food processing plants.

Factors such as temperature uniformity, precise temperature control, and low energy consumption should be considered when selecting a dehydrator for food processing applications.

Electronics Manufacturing

In the realm of electronics manufacturing, ovens serve multiple purposes, including curing adhesives, drying components, and eliminating moisture from printed circuit boards. Their ability to provide uniform temperature distribution and expedited drying times makes them invaluable in ensuring the reliability and performance of electronic components.

As with food processing, temperature uniformity, precise temperature control, and low energy consumption are essential factors to consider when selecting a drying oven for electronics manufacturing.

Pharmaceutical Industry

The pharmaceutical industry also relies heavily on ovens for drying for various applications, such as sterilization, depyrogenation, and drying of raw materials and finished products. These processes help ensure the safety and quality of the materials sensitive to pharmaceutical products, making drying ovens an indispensable tool in this industry.

When selecting a dehydrator for pharmaceutical curing applications only, it’s crucial to consider factors like temperature uniformity, precise temperature control, and low energy consumption.

Laboratory Uses of Ovens for Drying

In addition to their industrial applications, industrial ovens are commonly used in laboratories for a range of tasks, such as glassware drying, dry sterilization, and material testing.

Next, we’ll delve into these laboratory uses, emphasizing the importance of drying ovens in achieving accurate and consistent results.

Glassware Drying

Laboratories rely on ovens for drying to remove moisture from glassware and other equipment, preventing contamination and ensuring accurate results. Properly dried glassware is crucial for guaranteeing that it is clean and ready for subsequent use in laboratory or industrial settings.

Various types of ovens for drying, such as convection, vacuum, and conveyor dehydrator furnaces, can be employed for glassware dehydrators, depending on chamber size and the specific requirements of the laboratory.

Dry Sterilization

Drying ovens, also known as dry heat ovens, can be used for heating and drying sterilization, a process that utilizes hot air or dry heat to eliminate microorganisms from objects. This method of sterilization is especially useful for heat-resistant materials and equipment, as it does not require the use of liquid sterilants.

With their ability to provide consistent temperature conditions, drying ovens play an essential role in ensuring safe and effective dry sterilization in laboratory settings.

Aging Tests and Material Testing

In aging tests and material testing, ovens simulate long-term exposure to various conditions, helping researchers evaluate material properties and performance. By baking aging and subjecting materials to temperatures and environmental conditions that mimic real-world usage, researchers can:

- Forecast the service life and behavior of materials in actual applications

- Determine the effects of aging on material properties

- Assess the durability and reliability of materials

- Identify potential weaknesses or vulnerabilities in materials

- Develop strategies to improve material performance and longevity

This information is invaluable in the development of new materials and products, making ovens an essential tool in material testing laboratories.

Customizing Ovens Drying for Specific Needs

Although standard ovens are versatile and fit many applications, some scenarios may necessitate customization to satisfy unique requirements. In the following sections, we’ll explore options for tailoring drying ovens to specific needs, including:

- Stainless steel interiors

- Extra insulation

- Programmable controls

Stainless Steel Interior

A stainless steel interior offers improved durability, corrosion resistance, and ease of cleaning. In addition to its sleek appearance, stainless steel is highly resistant to rust and corrosion, making it an ideal choice for industrial settings and laboratories alike.

When customizing a drying oven with a stainless steel interior, it’s important to consider additional features such as extra insulation, programmable controls, and specialized coatings to further enhance the oven’s performance and durability.

Extra Layer of Insulation

An extra layer of insulation can enhance temperature stability and reduce energy consumption in ovens. By minimizing heat loss and improving the efficiency of heat treating the oven, additional insulation can lead to cost savings and a more sustainable drying process.

When adding an extra layer of insulation, it’s essential to choose the appropriate insulation material, such as fiberglass, foam, or other materials, depending on the specific requirements of the application.

Programmable Controls

Customizable controls allow users to create and save specific drying profiles for different materials and applications, providing precise temperature control and ensuring optimal dehydrator conditions. Programmable controls can help streamline processes, conserve energy, and guarantee consistent outcomes, making them a valuable addition to any dehydrator.

When customizing an oven with programmable controls, it’s important to consider the compatibility of the controls with the specific oven model and the desired level of customization.

Maintenance Tips for Drying Ovens

Appropriate maintenance is crucial for extending your drying oven’s lifespan and guaranteeing peak performance. Next, we’ll offer advice for maintaining your dehydrator, encompassing regular cleaning, calibration checks, and component inspection.

Regular Cleaning

Keeping the oven interior clean prevents contamination and ensures consistent drying performance. When cleaning the oven interior, it’s essential to use a soft cloth and a mild detergent to avoid causing damage. Additionally, it’s important to unplug the oven before cleaning and to wear protective gloves and eyewear during the process.

Regular cleaning of the oven interior not only prolongs the life of the oven but also helps maintain its performance and efficiency.

Calibration Checks

Periodic calibration ensures accurate temperature readings and optimal drying conditions. Calibration checks involve comparing the instrument’s readings to a known standard for accuracy, such as a thermometer or a standard sample. If the readings are not within the acceptable range, it may be necessary to adjust or recalibrate the instrument.

Regular calibration checks are essential for maintaining the reliability of your drying oven and ensuring consistent results.

Component Inspection

Regularly inspecting heating elements, fans, and other components can help identify potential issues before they become costly problems. By verifying that all components are functioning properly and meeting the required specifications, you can ensure that your drying oven remains in peak condition and continues to deliver reliable results.

Regular component inspection is an essential aspect of drying oven maintenance and should not be overlooked.

Summary

It is an essential tool in various industries and laboratories, thanks to its versatility, precise temperature control, and ability to cater to a wide range of applications. From food processing and electronics manufacturing to pharmaceuticals and material testing, it is used to ensure consistent, reliable results. As we’ve explored in this blog post, understanding the different types of ovens for drying, their key features and proper maintenance practices will help you make an informed decision when selecting the perfect drying solution for your specific needs. So, whether you’re drying glassware, sterilizing equipment, or conducting aging tests, a drying oven is an indispensable partner in achieving your desired outcomes.

Certified MTP has the largest selection of Lab Ovens, Grieve Ovens Large Capacity Industrial Bench Ovens, Convection Ovens and Benchtop Ovens, Vacuum Ovens, Industrial Furnace Ovens, and Despatch Ovens

For curing concrete in the field, we recommend the Concrete Curing Box (165qt. Heat Only)

Frequently Asked Questions

What is an oven for drying?

A drying oven is a heated chamber used to remove moisture and other solvents from objects using a fan or turbine that sparks convection.

What is the difference between an oven for drying and a regular oven?

Ovens for drying are specifically designed to remove moisture from the chamber to quickly dry samples, as they introduce fresh dry air to the work chamber while simultaneously expelling warm moist air. In contrast, regular ovens are designed to heat or cook and simply recirculate the same air around the chamber.

What is the name of the oven for drying?

The name of the drying oven is a Convection Drying Oven, which uses high temperatures to quickly dehydrate products for pre-heating, baking, aging, sterilization, and thermal storage.

What is the function of the dry oven?

A dry oven is a heated chamber used to remove water, moisture, and other solvents from objects by convection heating and drying.

What are the main types of ovens for drying?

The main types of ovens are convection, vacuum and conveyor furnaces.

Related Blogs to Drying Ovens:

Muffle Furnace: Unlocking the Benefits

Benchtop Muffle Furnaces for Laboratories

The Importance of Material Testing Ovens

Key Considerations for Choosing Your Industrial Oven or Furnace

Ignition Oven: A Guide to NCAT Asphalt Content Furnace Tech

Understanding Rolling Thin Film Oven Testing Equipment

Despatch Oven: The Power of Industrial Ovens and Furnaces

Laboratory Convection Oven: Benefits and Applications

The Benefits of a Lab Convection Oven

Gravity Convection Oven: Unlock the Benefits

Replacing a Sheldon Lab Oven Door Gasket

A Guide to Grieve Ovens and Industrial Oven Manufacturing

An Overview Despatch Oven: The Leader in Industrial Ovens

The Ultimate Guide to Industrial Oven Manufacturers

Find the Perfect Heat Treat Oven for Your Needs

Quincy Lab Ovens: Discover the Benefits

Vacuum Oven: Unlocking the Benefits

The Benefits of Lab Oven for Heating and Drying

What is Pyrolytic Oven Cleaning and Is It Worth it?

Get the Best Lab Oven for Your Research