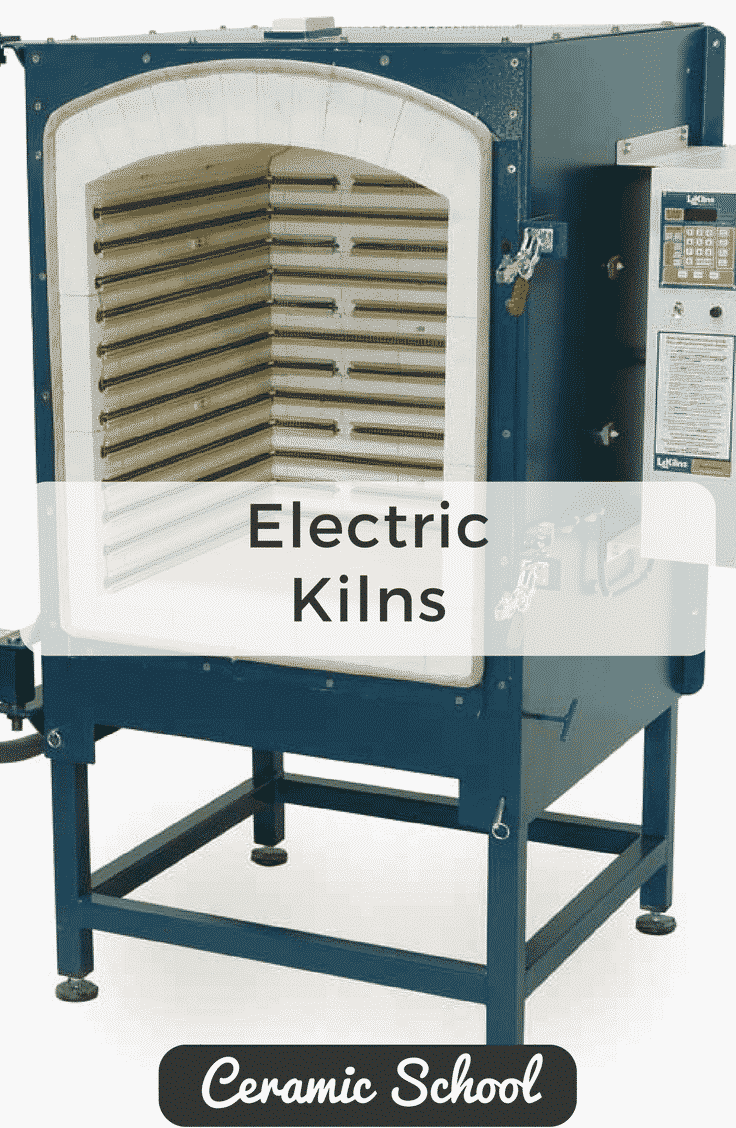

Are you in search of the ideal electric kiln for your ceramic projects? Navigating the options and pinpointing the right fit can be daunting. Our guide dives into the essentials of electric kilns for ceramics, from their operation and benefits to the different types available. We address practical considerations like space, temperature ranges, and budgets to ensure you find a kiln that fits your requirements with precision. Additionally, we highlight trusted brands and discuss ongoing maintenance to facilitate your crafting journey with confidence and clarity.

Key Takeaways

- Electric kilns for ceramics efficiently translate electric power into heat via metal coils and offer precise temperature control, making them preferred by both hobby potters and small ceramics businesses.

- When selecting an electric kiln for ceramics, important considerations include space and location for safe operation, firing temperature and cone range compatibility, kiln size and capacity for intended projects, and budget for both purchase and operational costs.

- Regular maintenance of electric kilns for ceramics, including inspections, cleaning, and replacement of elements, as well as troubleshooting common issues, is essential for its longevity and optimal performance.

Understanding Electric Kilns for Ceramics

Electric kilns for ceramics, a popular choice, convert electrical energy into heat effectively through metal coils known as heating elements. This heat is efficiently retained within the kiln’s walls and lid, thanks to the strategic placement of refractory ceramic material such as fire bricks or sometimes ceramic fiber. The heat in these pottery kilns influences the final appearance of glazes and clays, providing ceramic artists with a reliable and versatile tool for their creations.

Having understood what an electric kiln is, we can dissect its components further.

Components of Electric Kilns for Ceramics

The heart of an electric kiln is its heating elements, metal coils that generate heat when electricity passes through them. These heating elements are typically positioned in grooves in the kiln’s walls, providing a uniform temperature distribution crucial for the firing process. The kiln’s insulation, consisting of refractory ceramic material, acts as the protective shell, preserving heat and ensuring stable firing conditions. Temperature regulation is managed by controllers, thermocouples for temperature measurement, and relays for switching the heating elements on and off, ensuring precise control over the firing process.

Additionally, electric kilns are equipped with various structural components like:

- lid latches

- lifters

- door handles

- stands

These components ensure user safety and facilitate maintenance. Having become familiar with the components of an electric kiln, it’s time to explore the benefits they offer.

Advantages of Electric Kilns for Ceramics

Electric kilns for ceramics offer numerous advantages, making them the perfect kiln choice for both hobby potters and small ceramics businesses. Some of the advantages include:

- Precise temperature control facilitated by electronic controllers and thermocouples

- Custom firing schedules to ensure ceramics reach the correct temperature

- Highly reliable and predictable results for ceramic artists

Electric kilns require less infrastructure for installation than gas kilns, making them a practical choice for those with space constraints. Furthermore, the kilns’ flexibility allows artists to fire small batches or conduct glaze tests efficiently, making them a popular choice for a range of ceramicists.

Having grasped the advantages of electric kilns, we can now turn our attention to the various types available.

Types of Electric Kilns

Electric kilns come in two main types: top-loading and front-loading, each offering different accessibility options depending on the user’s needs. Top-loading electric kilns are popular for personal and small studio use, with their easily accessible lids and modular sections offering great flexibility. On the other hand, front-loading electric kilns are particularly well-suited for handling larger pieces and facilitating higher volume production environments due to their easy access to the kiln’s interior.

Armed with knowledge of electric kilns and their types, we can now be ready to consider the factors that matter when choosing the perfect kiln for your needs.

Factors to Consider When Choosing an Electric Kiln

Selecting the right kiln is crucial for achieving your desired ceramic results. There are several factors to consider while choosing an electric kiln, including:

- Space and location requirements

- Firing temperature

- Kiln size

- Budget

Each category plays a significant role in ensuring you have the right equipment for your ceramic artistry, whether in a professional setting or a home studio.

We will discuss these factors individually.

Space and Location Requirements

The location and space of your kiln are crucial factors to consider. Proper ventilation is essential to expel moisture, gases, and fumes emitted during the firing process, ensuring a safer working environment and cleaner firings. A kiln should be positioned on a stable and level surface with a minimum of 18 inches of clearance from any surrounding walls or flammable materials.

Larger kilns may require greater power, necessitating the consultation of an electrician to ensure the proper outlet and breakers are installed for the kiln’s voltage and amperage. By considering these space and location requirements, you can ensure a safe and efficient environment for your kiln operations.

Firing Temperature and Cone Range

Understanding the concept of firing temperature and cone ranges is key to achieving the desired results in your ceramic pieces. Different clay bodies and glazes mature at various temperatures, classified into low-fire, mid-range, and high-fire materials. For example, low-fire earthenware typically reaches optimum hardness between 1745℉ and 2012℉, while high-fire stoneware requires temperatures ranging from 2381℉ to 2455℉. The color of the clay and glazes after firing largely depends on the mineral content and the firing temperature, adding to the uniqueness of each ceramic piece.

By understanding these firing temperatures and cone ranges, you can select the most appropriate kiln for your artistic needs.

Kiln Size and Capacity

Selecting the right kiln size and capacity is paramount for your ceramic projects. Electric kilns come in a varied range, from small tabletop models to large units capable of holding numerous pieces. The kiln size should be selected based on the size and quantity of ceramic pieces intended for firing, ensuring there is enough space around each piece for proper air circulation.

For instance, small kilns, like the Skutt KMT-818, can fire up to 12 bowls at a time, whereas large kilns used by professional potters can hold 50 or more 6-inch bowls, suitable for high-volume production. By considering the size and capacity of the kiln, as well as other kilns available, you can ensure efficient and consistent firings for your ceramic pieces.

Budget and Price Range

Your budget plays a significant role in deciding the electric kiln you choose. While electric kilns are typically more affordable than gas and wood-fired kilns, their price can vary significantly based on size and additional features. Prices for small electric kilns start at around $1,000, with larger models featuring advanced capabilities exceeding $20,000.

It’s important to weigh not just the initial purchase price of the kiln, but also the longer-term savings in energy and reduced maintenance expenses. By taking into account these factors, you can find a kiln model that fits your budget without compromising on quality and performance.

Popular Electric Kiln Brands and Models

With so many electric kilns available in the market, it can be challenging and difficult to decide on the right one. Let’s explore some renowned brands like Skutt, Paragon, and Olympic, and their popular models, to help you make an informed choice.

Skutt Electric Kilns

Skutt is a well-known brand offering kilns that cater to various ceramics creators. The brand offers two prominent series: the KilnMaster and the Production Series. The KilnMaster Series is known for its advanced features that provide users with precise control over the firing process. The Production Series, on the other hand, includes large capacity kilns designed to meet the demands of high volume ceramic production.

With their versatile offerings, Skutt electric kilns cater to individual ceramic artists, educational settings, and commercial production environments.

Paragon Electric Kilns

Paragon kilns, renowned for their robustness and longevity, offer artists the flexibility required to tailor their equipment. The Paragon electric kilns are equipped with digital controllers that ensure precise control over firing schedules and temperatures.

Their customization options make ceramic kilns a popular choice among ceramicists who want to modify their kiln to best suit their needs.

Olympic Electric Kilns

Olympic Kilns provides a diverse selection of electric kiln sizes, catering to different needs, from individual artists to educational settings. Their kilns are designed with energy efficiency and reliable performance as focal points, making them an appealing choice for those who value long-term operational savings and consistent results.

Having discussed some popular electric kiln brands and models, we can now move on to the essential accessories and add-ons that enhance their functionality.

Accessories and Add-Ons for Electric Kilns

To optimize your electric kiln’s performance and make your ceramic firing process smoother, certain accessories and add-ons can be incredibly helpful. These include kiln furniture, controllers, and safety equipment.

We will discuss each of these accessories in detail.

Kiln Furniture

Kiln furniture, including shelves, stilts, and posts, is essential for supporting and separating ceramic pieces during firing to prevent them from sticking to each other or the kiln walls. The use of kiln furniture allows for the stacking and firing of pieces in multiple layers, leading to efficient use of kiln space.

Regular cleaning and maintenance of kiln furniture are necessary to ensure its longevity and prevent potential damage to your ceramic pieces.

Controllers and Upgrades

Controllers play a pivotal role in managing the firing process in an electric kiln. While manual controllers are simple to use, digital computer controllers offer:

- Precise programming of firing schedules

- Automatic control over temperatures and time changes

- Interactive touchscreens

- Wi-Fi connectivity for remote monitoring

- Extensive memory for various firing programs

Advanced digital controllers like TAP and Genesis are essential in achieving consistent and precise results in your ceramic firing processes.

Safety Equipment

Safety should always be a priority when working with electric kilns for ceramics. Essential safety equipment includes:

- Heat-resistant gloves to protect against heat and fumes

- Safety glasses to protect your eyes from heat and fumes

- Infrared glasses for viewing through kiln spy holes to protect your eyes from intense radiant heat

- A fire extinguisher is specifically rated for electrical fires readily accessible near the kiln to counteract fire risks.

With these safety measures in place, you can ensure a safe and secure firing process.

Maintenance and Care for Your Electric Kiln

Ensuring the longevity and optimal performance of your electric kiln requires regular maintenance and care. This includes regular inspections, cleaning, and troubleshooting common issues.

We will discuss these aspects in depth.

Regular Inspections

Regular inspections ensure your electric kiln’s structural integrity and electrical safety. This includes tightening screws in the lid band, handling kiln bricks with care, and closing the kiln lid gently to prevent potential damage. Regularly inspect the kiln’s wiring for signs of damage, such as burning, brittleness, or charring, and contact a technician if any issues are found.

By performing these regular inspections, you can ensure your kiln runs efficiently and safely.

Cleaning and Replacing Elements

Keeping your kiln clean and replacing elements when necessary is vital for your kiln’s performance and longevity. Here are some steps to follow:

- Start by manually removing larger debris from exploded pottery and scraping off any glaze, slip, or clay from the kiln’s sidewalls.

- Regularly clean the thermocouple with a brush if it’s flaking.

- Replace both the thermocouple and relays when they show signs of corrosion or wear out from high temperatures and constant switching.

By following these steps, you can ensure that your kiln stays in good condition and continues to work effectively.

These maintenance steps help ensure your kiln continues to function optimally over time.

Troubleshooting Common Issues

Occasionally, you might encounter issues with your electric kiln. Some common problems include electrical noise issues, the kiln switching off during operation, and a non-heating kiln. Each of these issues can be resolved by ensuring a proper ground to the kiln, checking for an error code and assessing the electric power supply, and ensuring the kiln is set to the correct voltage, respectively.

By promptly addressing these common issues, you can prevent potential damage to your kiln and ensure smooth operation.

Summary

In conclusion, electric kilns for ceramics are a vital tool for ceramicists, transforming raw clay into beautiful pieces of art. Understanding the components, advantages, and types of electric ceramic kilns used, as well as factors to consider when choosing one, can help you find the perfect kiln for your needs. Renowned brands like Skutt, Paragon, and Olympic offer a range of models to suit different needs and budgets. Regular maintenance and care, along with essential accessories and safety equipment, ensure optimal performance and longevity of your kiln. Remember, the journey to creating stunning ceramic pieces begins with choosing the right kiln.

Certified MTP has the largest selection of Industrial Ovens and Lab Bench Convection Ovens in their wide selection of Benchtop Ovens from manufacturers such as Quincy Lab Ovens, Despatch Ovens, Lab Companion Ovens, Cascade TEK Ovens, Grieve Ovens. They are also the leader if Industrial Furnace Ovens such as Thermolyne Furnaces and Carbolite Furnaces, including kiln for ceramics.

Frequently Asked Questions

How expensive is it to run an electric kiln?

Running an electric kiln can cost between $0.08 and $0.38 per kilowatt hour, with the average in the USA being $0.12 for residential and $0.10 for commercial. These rates may vary based on location and usage.

What kiln should I buy as a beginner?

As a beginner, I recommend purchasing an electric kiln. It’s easier to use, install, and doesn’t require as much attention as gas kilns. Most potters find it suitable for their needs.

Do electric kilns for ceramics use a lot of electricity?

Yes, electric kilns can use a significant amount of electricity, with smaller ones drawing 1.5 to 1.8 kilowatts and larger ones drawing up to 11kW. Be sure to consider the energy requirements when estimating firing costs.

How long does it take to fire pottery in an electric kiln?

It takes about 12 hours to fire pottery in an electric kiln and another 12 hours to cool, although the difference in the cooling time depends on the size of the kiln.

What is an electric kiln?

An electric kiln uses electrical energy to produce heat for firing ceramics, making it a popular and convenient choice for ceramicists.

Related Blogs to Electric Kilns for Ceramics:

Muffle Furnace: Unlocking the Benefits

Benchtop Muffle Furnaces for Laboratories

The Importance of Material Testing Ovens

Key Considerations for Choosing Your Industrial Oven or Furnace

Ignition Oven: A Guide to NCAT Asphalt Content Furnace Tech

Understanding Rolling Thin Film Oven Testing Equipment

Despatch Oven: The Power of Industrial Ovens and Furnaces

Laboratory Convection Oven: Benefits and Applications

The Benefits of a Lab Convection Oven

Gravity Convection Oven: Unlock the Benefits

Replacing a Sheldon Lab Oven Door Gasket

A Guide to Grieve Ovens and Industrial Oven Manufacturing

An Overview Despatch Oven: The Leader in Industrial Ovens

The Ultimate Guide to Industrial Oven Manufacturers

Find the Perfect Heat Treat Oven for Your Needs

Quincy Lab Ovens: Discover the Benefits

Vacuum Oven: Unlocking the Benefits

The Benefits of a Drying Oven for Industrial Applications

The Benefits of Lab Oven for Heating and Drying

What is Pyrolytic Oven Cleaning and Is It Worth it?

Get the Best Lab Oven for Your Research

Field Oven vs Laboratory Oven: Which is More Accurate?