Have you ever wondered how engineers ensure the stability and safety of massive structures like bridges, dams, and buildings? One critical aspect of engineering projects is understanding the characteristics of the soil on which these structures are built. That’s where triaxial testing comes into play. In this blog post, we’ll delve into the world of triaxial testing, a powerful technique for analyzing soil properties and its vital role in geotechnical engineering.

Key Takeaways

- This article provides an overview of the fundamentals and components of triaxial testing, including its stages, soil specimen preparation and test results analysis.

- The procedure involves saturation, consolidation and shearing stages to evaluate a soil sample’s mechanical properties through axial strain/principal stress calculation & Mohr’s circle.

- Triaxial tests are standardized methods used in geotechnical engineering with advantages such as accuracy & efficiency. Certain limitations must be considered.

Triaxial Test Fundamentals

Triaxial testing is a laboratory procedure used to assess the triaxial shear strengths of soil specimens exposed to varying drainage conditions in the field. This testing method allows engineers to measure important parameters such as total stress and effective stress parameters, pore water pressure, fluid pressure, and volume changes. Triaxial shear testing offers numerous benefits, including the ability to test any type of soil, control drainage conditions, measure pore water pressure, and assess volume changes.

The ensuing sections will delve into the specifics of the triaxial shear test, the various types of triaxial tests, and the steps involved in the triaxial shear test procedure. Join us as we uncover the intricacies of triaxial testing.

Triaxial Shear Test

First developed by Arthur Casagrande in 1930, the triaxial shear test is a procedure that evaluates the mechanical characteristics of a soil sample by subjecting it to an axial stress, in three different directions using a triaxial shear test apparatus. The fundamental concept of a triaxial shear test involves subjecting a cylindrical soil specimen to axially symmetric stresses with three primary stresses inside a test cell. It is distinct from a direct shear test, which measures shear strength along a single plane.

Comprehending the behaviour of a soil sample is facilitated through the triaxial shear test. This method enables the derivation of fundamental material parameters, such as the angle of shearing resistance, apparent cohesion, and dilatancy angle. The effective stress concept plays a crucial role in triaxial testing. Effective stress is the stress on a sample that can be quantified by employing a porous surface on one platen and measuring the pressure of the fluid during the triaxial compression test. The three primary stresses applied to the soil sample consist of two stresses resulting from water pressure and one applied stress from the upper portion of the cell.

Although triaxial testing is not a universal solution, it is a standard test method. Its versatility and accuracy render it indispensable in geotechnical engineering for characterizing different types of soils and evaluating their mechanical properties.

Types of Triaxial Tests

There are three types of conventional triaxial tests: Unconsolidated Undrained (UU), Consolidated Undrained test (CU), and Consolidated Drained Test (CD). Each type has its specific applications and provides valuable information about soil behavior under different conditions.

The UU test is used to determine the undrained shear strength (cu) of soil, which is essential for evaluating soil stability in the short term.

In a CU test, drainage is allowed while cell pressure is applied to the sample, and deviator stress is applied while maintaining the cell pressure constant without provision for additional drainage. CU tests help determine strength parameters based on effective stresses and provide a faster rate of shearing than CD tests.

The CD test maintains constant cell pressure while allowing drainage and slowing the loading rate to avoid excess pore pressure. Engineers primarily use it to determine cohesion and the angle of internal friction. They examine three distinct lateral pressure values on the sample during the test. This process takes into account both air and fluid pressures. By using the CD test, engineers can accurately assess the sample’s stability and strength properties.

Triaxial Test Apparatus and Sample Preparation

Preparing a soil sample for triaxial testing requires specialized equipment and meticulous attention to detail. The triaxial test apparatus itself consists of several key components, including:

- Loading frame

- Pressure chamber

- Pressure transducer

- Load cell

- Data acquisition system

The upcoming sections will elaborate on the components of the triaxial test apparatus alongside the process of forming, trimming, and mounting soil samples for testing.

Keep Reading: Laboratory Soil Testing: Unlocking the Secrets.

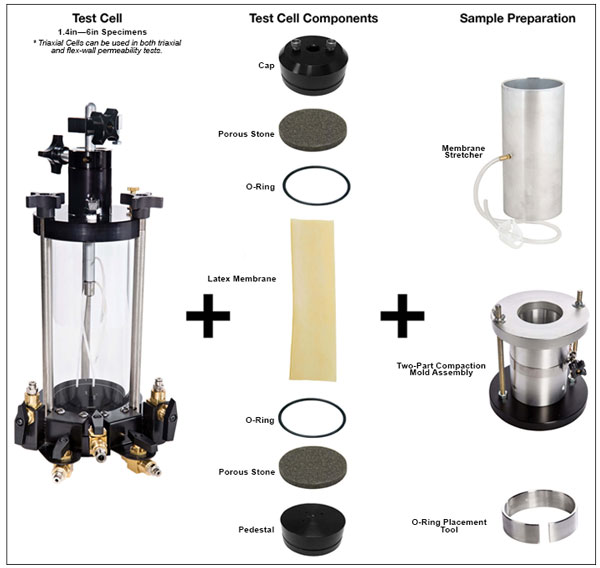

Components of Triaxial Test Apparatus

A triaxial test apparatus typically includes a triaxial cell, load frame, pressure chamber, pressure gauge, valve, triaxial cell accessories (such as caps and pedestals), and a triaxial control panel for regulating and monitoring pressures. Each component plays a crucial role in the testing process. For instance, the load frame is used to apply a vertical load to the specimen in the triaxial cell, while the pressure chamber applies a confining pressure to the specimen within the cell. The pressure gauge measures the pressure in the chamber, and the valve controls the flow of fluid in and out of it.

Triaxial cell accessories, like porous stones, caps, and pedestals, are essential for ensuring accurate test results.

- Porous stones ensure a consistent distribution of the confining pressure to the specimen in the triaxial cell.

- Caps secure the specimen in the cell.

- Pedestals support the specimen. The triaxial control panel is responsible for modulating and surveying pressures in the triaxial cell.

Soil Specimen Preparation

Forming, trimming, and mounting soil samples for triaxial testing are critical steps to ensure accurate test results. Soil samples are formed by extracting a sample of soil from the ground and compressing it into a cylindrical shape. The importance of forming soil samples lies in guaranteeing that the sample is representative of the soil being examined.

Trimming soil samples involves cutting them to the required size and shape, ensuring that the test specimen is of the correct size and shape for the triaxial test.

Mounting soil samples entails the following steps:

- Affix the sample in a triaxial cell.

- Ensure that the sample is firmly secured.

- This step guarantees that the sample is firmly held in place during the triaxial test, allowing for accurate measurements of soil properties.

Triaxial Test Procedure and Stages

The triaxial test procedure consists of several stages, including saturation, consolidation, and shearing. Each stage plays a crucial role in obtaining accurate test results, and understanding these stages is vital for interpreting the data obtained from triaxial tests.

The upcoming sections will delve into each stage thoroughly, highlighting their significance in triaxial testing.

Saturation Stage

The saturation stage is the process of fully saturating the soil or rock sample with water before testing begins. This stage ensures that the sample is in a completely saturated state, with all void spaces filled with water. Achieving full saturation in the soil sample is essential, as it enables the precise measurement of the shear strength and other mechanical properties of the sample.

During the saturation stage, engineers determine Skempton’s B value by conducting a B-check. They seal the rubber membrane over the specimen drainage while increasing the cell pressure by approximately 50 kPa. This measure assesses the degree of saturation of the soil specimen and ensures adequate saturation for testing.

More Reading: Unlocking the Power of Concrete Resistivity Testing.

Consolidation Stage

The triaxial test process includes a consolidation stage. This stage is used to test specimens and achieve the necessary effective stress state for shearing the specimen. The consolidation stage involves:

- Applying confining pressure to the specimen

- Maintaining constant back pressure until volume change is insignificant

- Allowing excess pore pressure to dissipate

The consolidation stage is of paramount importance, as it guarantees that the specimen is in the desired effective stress state for shearing, which is essential for obtaining precise results from the triaxial test.

During the consolidation stage, we increase the cell pressure and maintain constant back pressure to ensure minimal volume change in the sample. This process prepares the sample for the subsequent shearing stage, where we evaluate the mechanical properties of the soil.

Shearing Stage

The shearing stage of triaxial testing is where the soil sample is subjected to shear stress and its mechanical properties are evaluated. The process of the shear stage involves the following steps:

- Deform the sample with a constant strain using a movable load frame platen, either moving upward or downward.

- Monitor the specimen’s response by plotting the deviator stress (q) or effective principal stress ratio (1/3) against the axial strain (a).

- Continue monitoring until the prescribed failure criterion is attained.

You can use the peak deviator stress or peak effective principal stress ratio to determine if a failure occurs during shearing. Additionally, monitor constant stress and excess pore pressure or volume change values for signs of failure. Observe a specific axial strain value to detect failure during the shearing stage. Measure these parameters consistently to ensure accurate monitoring throughout the process. By tracking these values, you can effectively identify when failure happens during the shearing stage.

The outcomes of the shearing stage, such as the shear strength and mechanical properties of the material, are critical for understanding the behavior of the soil under various loading conditions and for designing foundations, embankments, and other geotechnical structures.

Analyzing Triaxial Test Results

Once the triaxial test is completed, the data obtained from the test must be carefully analyzed to gain insights into the soil’s properties and behavior.

The ensuing sections will illuminate the methods for calculating axial strain and principal stresses, as well as elucidate the role of Mohr’s circle in assessing shear resistance and other soil properties.

Calculating Axial Strain and Principal Stresses

Axial strain is a crucial parameter in triaxial testing, as it provides valuable information about the deformation characteristics of the soil sample under applied stress. To calculate axial strain, divide the change in length (L) by the initial length (L0).

In addition to additional axial stress and strain, principal stresses at failure are essential for understanding the stress distribution within the soil sample during testing. The minor principal stress is equal to the chamber pressure.

These calculations, along with other parameters such as average cross-sectional area, are essential in determining the mechanical properties of the soil sample, including its shear strength vertical stress, and deformation behavior. Proper analysis of axial strain and principal stresses allows engineers to make informed decisions when designing foundations, embankments, and other geotechnical structures.

Mohr’s Circle and Shear Resistance

Engineers use Mohr’s circle, a two-dimensional graphical representation of the Cauchy stress tensor transformation law, to analyze principal and maximum shear stresses in a stressed body. By employing Mohr’s circle, they can determine the shear resistance of soil by plotting the principal stresses. They also calculate the maximum shear stress using this graphical tool. Mohr’s circle simplifies the visualization and analysis of complex stress states. This tool helps engineers ensure the stability and safety of various structural and geotechnical projects.

Using Mohr’s circle to assess soil properties has several advantages:

- It allows for the evaluation of other soil properties, including the angle of internal friction, cohesion, and modulus of elasticity.

- By analyzing the data obtained from triaxial testing using Mohr’s circle, engineers can better understand the soil’s behavior under various loading conditions.

- It helps in designing safe and efficient geotechnical structures.

Pore Water Pressure Measurement in Triaxial Tests

Measuring pore water pressure during triaxial testing is essential to guarantee precise test results. Pore water pressure represents the pressure within the soil’s voids, which can significantly influence the soil’s mechanical behavior. Accurate measurement of pore water pressure allows engineers to better understand the soil’s response to applied stresses and design structures accordingly.

Pore pressure measurement transducers are employed to measure pore water pressure during triaxial testing. Additionally, Bishop’s pore pressure apparatus enables measuring the pressure of fluids like water and oil. Moreover, it facilitates determining the pore pressures of gases in a sample. Proper measurement of pore water pressure during triaxial testing ensures reliable test results and a better understanding of the soil’s mechanical properties.

Triaxial Testing Standards and Applications

Triaxial testing is a widely recognized and standardized method for evaluating soil properties. Various organizations, such as ASTM International, British Standards, and the International Organization for Standardization (ISO), have established triaxial testing standards. These standards ensure uniformity and reliability in the triaxial testing machine and process, making triaxial testing an invaluable tool in geotechnical engineering.

Triaxial testing evaluates the strength and deformation characteristics of soils and rocks, essential for designing and constructing geotechnical structures like foundations and embankments. This testing method is crucial in assessing slope stability, and ensuring the safety of various engineering projects. Additionally, triaxial testing helps determine the bearing capacity of soils, which is vital for the structural integrity of constructions. The insights gained from triaxial testing enhance the efficiency and reliability of engineering solutions in geotechnical applications.

Advantages and Limitations of Triaxial Testing

With its numerous advantages over other testing methods like direct shear tests, triaxial testing provides a reliable and accurate technique for evaluating soil properties, including shear strength, compressibility, and permeability. Additionally, triaxial testing requires less time and labor than other testing methods, making it a cost-effective option for soil analysis.

However, triaxial testing has its limitations. It can only be used to measure properties of soils that are relatively uniform, and it requires specialized equipment and expertise to execute the tests. Despite these restrictions, triaxial testing remains an essential tool in geotechnical engineering for characterizing various types of soils and assessing their mechanical properties.

Summary

In conclusion, triaxial testing is a powerful technique for analyzing soil properties and plays a vital role in geotechnical engineering. Understanding the fundamentals of triaxial testing, including test types and equipment, is essential for gaining insights into soil behavior. Analyzing triaxial test data and results, along with exploring practical applications, aids engineers in designing safe structures. Despite its limitations, the benefits of triaxial testing significantly outweigh its drawbacks, highlighting its importance in engineering. Consequently, triaxial testing remains an indispensable tool, providing crucial information that ensures the efficiency and safety of engineering projects.

Frequently Asked Questions

What is a triaxial test used for?

A triaxial test is used to determine the shear strength of a cylindrical core soil or rock sample by attempting to replicate the in-situ stresses of the original place where the sample was taken.

What is the difference between the triaxial test and the shear test?

The key difference between triaxial testing and direct shear testing lies in how they generate confining pressures. In triaxial testing, a fluid chamber simulates stresses from surrounding soil materials by applying confining pressures on all sides. In contrast, direct shear testing always has a horizontal failure plane. It offers insights into the complete state of stress during the test. However, direct shear tests only reveal the stresses at failure.

What are the different types of triaxial tests?

Triaxial tests are of three main types: Consolidated Undrained (CU), Consolidated Drained (CD) and Unconsolidated Undrained (UU). These tests help study the shear strength and behavior of soil under various stress conditions.

What equipment is used in triaxial testing?

Triaxial Testing Equipment consists of Triaxial Cells, Triaxial Cell Accessories, Triaxial Control Panels, Load Frames, Load & Displacement Measurement, Triaxial Compression Data Acquisition Software, and Sample Preparation.

Why is it important to measure pore water pressure during triaxial testing?

It is important to measure pore water pressure during triaxial testing as it affects the soil’s mechanical behavior and response to applied stresses, thus ensuring accurate test results.