Rheometry is the science of deformation and flow, measuring how materials like polymers, foods, and industrial compounds withstand forces and behave under stress. If you’re seeking to grasp material consistency or enhance product quality, rheometry provides the essential data needed. This guide unpacks rheometry’s role in material analysis without delving into the complex specifics reserved for the following sections.

Key Takeaways

- Rheometry is critical for understanding the deformation and flow of materials under applied forces, and it employs specialized instruments called rheometers to measure properties such as viscosity, viscoelasticity, and flow behavior.

- Shear stress and shear rate are central to rheological analysis, with controlled stress rheometers measuring shear stress to characterize material behavior, and shear rate being particularly important when studying non-Newtonian fluids where viscosity changes with deformation rates.

- Rheometry has practical applications in various industries for quality control by simulating processing conditions and characterizing materials to ensure consistency, reliability, and help in diagnosing manufacturing issues.

Exploring the Fundamentals of Rheometry

Rheometry, a scientific field dedicated to the study of material deformation and flow under applied forces, offers a critical understanding of both qualitative and quantitative aspects of rheological properties. Rheological analysis predicts the complex behavior of fluids under various forces, like:

- Figuring out how a material or liquid deforms when an external force is applied

- Determining the viscosity of a fluid

- Analyzing the flow behavior of materials under different conditions

By studying rheology, scientists and engineers can gain valuable insights into the behavior of materials and develop better products and processes.

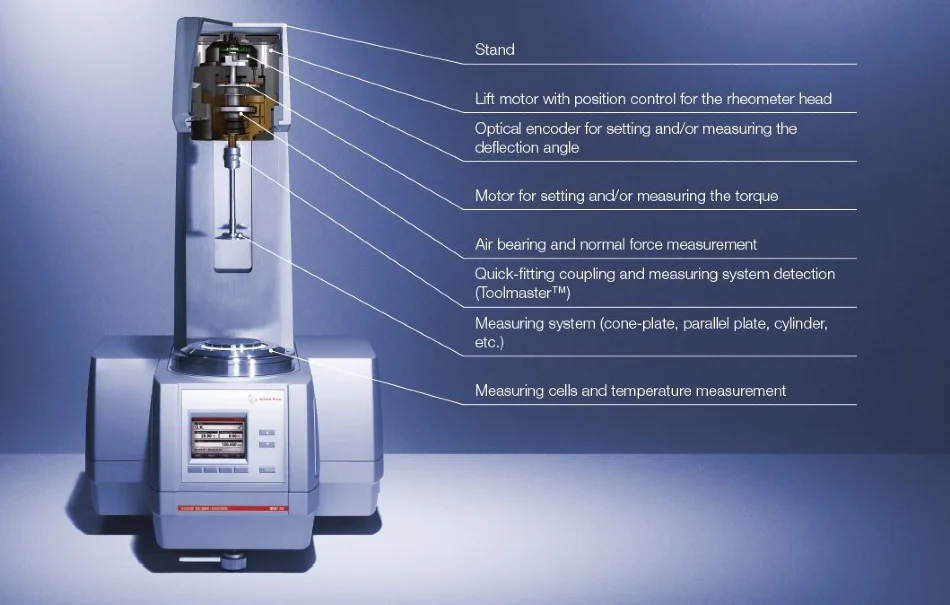

Viscosity is a fundamental concept in rheometry, reflecting a material’s internal resistance to flow. Factors that measure viscosity such as particle size influence it, providing an overview of a substance’s flow characteristics. Another key parameter is viscoelasticity, which evaluates a material’s deformation characteristics and energy dissipation when subjected to deforming forces. This is where rheometers come in. These specialized instruments measure rheological properties and are vital for accurately characterizing the complex flow behavior of a variety of materials, not just those with a consistent viscosity. By assessing these rheological parameters, researchers can gain valuable insights into material behavior.

The Role of Shear Stress in Rheological Analysis

In the realm of rheometry, shear stress plays a pivotal role. The force per unit area applied parallel to a material’s surface characterizes the material’s structure and flow behavior under applied stress and deformation conditions. Shear stress applied during rheological testing simulates real-world conditions like pumping, squeezing materials, or defining the force needed to start moving a material at rest.

Controlled stress rheometers employ applied torque, including electrical torque generated, to regulate stress and promote strain, thereby generating dependable data and facilitating an understanding of materials’ resistance to flow. Measuring and calculating shear stress from torque and shear surface area ensures laminar flow during testing, forming the backbone of viscosity calculations and material characterization.

Shear Rate: The Pulse of Rheological Measurements

Delving further into rheology introduces another key concept: the shear rate. Cone and plate rheometers, which use a shallow cone immersed in a liquid on a horizontal plate to measure torque, offer an effective method for measuring systems and studying flow behavior. This setup ensures the entire material sample experiences a constant shear rate during testing, providing consistent characterization.

Shear rate assumes particular significance in studying non-Newtonian fluids, where viscosity varies with different rates of deformation, underlining a non-linear relationship between shear stress and shear rate. The beauty of the shear rate lies in its consistency. Using a conversion factor, we calculate it, and it remains independent of the measuring system used in the rheometer. However, when using cone-and-plate geometry, one must ensure particles do not get trapped beneath parallel plates at the cone’s center, as it can affect measurement accuracy.

Importance of Shear Rate in Food Science

Rheometry extends its influence beyond laboratory experiments; it is also pivotal in the food industry. By evaluating the flow properties of ingredients and finished products, influences the overall consumer experience and ensures product standards are met. Mimicking the handling of food materials during processing or preparation gives insights into food behavior and the release of flavors and nutrients during chewing and digestion.

Shear rate is a key factor in determining the texture and sensory properties of food products. It’s used to optimize products like meat analogs and find the perfect creamy texture for milk alternatives and zero-fat yogurts. Understanding how food materials respond to different shear rates allows for the optimization of processing equipment, crucial for maintaining product quality and consistency.

From predicting food material flow during processing and transportation to managing the flow of non-Newtonian fluids like ketchup, the knowledge of shear rate proves indispensable in the food industry.

Shear Thinning Fluids and Their Behavior

In rheology, some fluids defy convention. Shear thinning fluids, characterized by a decrease in viscosity as the shear rate increases exhibit pseudoplastic behavior. The degree of shear thinning in complex fluids can be quantified by the power-law index, where a smaller index indicates a more pronounced shear thinning.

Various common materials, including ketchup, paints, and blood, exhibit shear thinning behavior, which is critical for their application and processing. This behavior is beneficial in processes like spraying and spreading, where a lower viscosity under high shear rates allows for easier application.

Viscoelasticity: A Key Rheological Parameter

Viscoelasticity adds another intriguing dimension to rheology. It refers to materials that exhibit a combination of viscous and elastic behavior when subjected to shear forces. These unique properties are assessed using rheometry. The storage modulus (G’) quantifies the elastic behavior of a material by indicating energy storage during deformation. In contrast, the loss modulus (G’’) measures the energy dissipated as heat due to viscous effects.

A rotational rheometer can determine a material’s overall viscoelastic response by measuring the complex shear modulus. The phase angle and the ratio of the loss modulus to the constant value of the storage modulus offer additional insights into the viscoelastic properties.

Oscillatory Testing for Viscoelastic Materials

Oscillatory testing emerges as a formidable technique in rheology. It involves applying a sinusoidal strain to a sample and measuring the amplitude sweep of the resulting stress to analyze its viscoelastic properties. Amplitude sweeps in oscillatory testing assess the material’s deformation behavior within the non-destructive range, determining the linear viscoelastic region where the structure is maintained.

If the storage modulus G’ is greater than the loss modulus G’’, the material behaves like a solid. Conversely, if G’’ is greater, it behaves like a liquid. Assessing G’ and G’’ curve behaviors helps evaluate gel strength or stiffness and behavior upon structural breakdown.

Frequency sweeps in oscillatory testing reveal how viscoelastic materials respond to different deformation rates, simulating conditions akin to both rapid and slow movements.

Controlled Stress vs. Controlled Strain Rheometers

Rotational rheometers primarily fall into two categories: strain-controlled, where a user-defined shear strain is imposed, and stress-controlled, where a user-defined shear stress is applied. Controlled stress rheometers are capable of measuring the torque response accurately, crucial for determining the applied shear stress and analyzing material behavior under stress.

These rheometers gradually increase stress to observe the yield point, crucial for determining yield stress and the onset of material flow. On the other hand, in controlled strain rheometers, the user sets the speed or deflection angle, and the instrument measures the strain rate resulting in torque using a separate torque re-balance transducer in the combined motor transducer mode.

Advanced Rheometry Techniques

Advanced techniques in rheometry, while offering an exciting exploration, are as fascinating as the fundamentals, if not more. Extensional rheometers, for instance, are key for materials subjected to tensile deformation, such as during injection molding and fiber spinning. They can measure extensional stress, viscosity, and uniaxial strain.

Methods in extensional rheometry can provide data on the strain hardening of elastic polymers and force requirements for peeling or separating adhesive films of purely elastic material under various conditions. Acoustic rheometers use high-frequency ultrasound waves to analyze the elasticity and viscosity of fluids with short relaxation times, based on sound speed and attenuation measurements.

Additionally, Falling plate rheometers offer insights into the extensional flow properties of test fluid by measuring the force necessary to extend the flow curve of a liquid between two plates against gravity.

Dynamic Rheology for Soft Solids

Dynamic rheology has a special place in the study of soft solids such as gels, pastes, and creams. It examines the viscoelastic characteristics of these materials, providing insightful data for various applications.

The storage modulus is particularly indicative of the elastic qualities of a soft solid’s viscoelastic behavior, reflecting its solid-state characteristics.

Capillary Rheometers for High Viscosity Fluids

Capillary rheometers are another powerful tool in rheometry. They are used to force liquid through a tube, providing a measure of both the flow rate and pressure drop. This allows for determining the shear rate and shear stress of the liquid. Their precision in generating specific shear rates makes them ideal for analyzing the flow properties of high-viscosity fluids such as polymer melts.

This makes them the preferred instrument for measuring points characterizing thermoplastic materials in research, particularly for measuring viscosity at high shear rates, pertinent to polymer processing.

Temperature Control in Rheological Measurements

Maintaining temperature control is quintessential in rheological measurements. Even small temperature changes can lead to significant changes in material properties like viscosity. Modern rheometers feature sophisticated temperature control devices, including a heat exchanger, to maintain sample temperature within 0.1°C of the set-up temperature range, which is crucial for accurate viscosity measurements.

Additionally, these rheometers analyze temperature-dependent viscoelastic behavior using oscillatory tests with a variable temperature profile and employ temperature sweep tests to study the behavior of soft solids across different temperatures.

Practical Applications of Rheometry in Quality Control

Rheometry goes beyond the realm of theoretical science, finding practical applications in quality control across various industries, thereby ensuring product consistency and reliability. Quality control laboratories use rheometry to simulate real-world processing conditions, thereby optimizing manufacturing processes such as injection molding and extrusion.

Rheological measurements support the development of new products and ensure material supply quality, minimizing reject rates and contributing to efficient reduction validation processes.

Rheometry in Action: Case Studies

Rheometry holds a significant place in a variety of real-world applications, highlighting the dynamic scope of rheological analysis, ranging from the food industry to biomedical applications. Capillary rheometers are instrumental in diagnosing processing issues within industrial settings, offering a way to analyze problems without halting production lines.

Continuous rheological monitoring of food, such as observing the changes in potato samples through heating and cooling cycles, underscores the importance of rheometry in ensuring quality and consistency in the food industry.

Summary

We’ve journeyed through the world of rheometry, exploring its fundamentals, understanding the role of shear stress and rate, delving into viscoelasticity, and unpacking advanced techniques. Additionally, we’ve seen how temperature control is crucial in rheological measurements and discovered its practical applications in quality control across various industries. Through real-world case studies, we’ve appreciated the immense value rheometry brings to the table.

Certified MTP has an elite selection of Asphalt Binder Testing tools and Rheometers, showcasing industry-leading brands for the Brookfield Viscometers, Saybolt Viscosity Bath, Marshall Stability Test Systems, Marshall Compactor Test Equipment and Molds, Marshall Water Baths for Asphalt Testing, Viscometers, and Sample Ejectors for Asphalt Extrusion.

Frequently Asked Questions

What is rheometry explained?

Rheometry is a technique used to measure the deformation of a material or liquid when a force is applied, and it forms the basis of rheology, the science of material deformation.

What is a rheometer used for?

A rheometer is used to measure the flow of viscous fluids in response to applied forces, providing insights into their rheology. It helps characterize the resistance to deformation and flow behavior of substances in a laboratory setting.

What is the meaning of rheology?

Rheology is the study of the flow and change of shape of matter, primarily in fluid or soft solid states. It involves understanding the deformation and flow behavior of materials.

What is shear stress and why is it important in rheological analysis?

Shear stress measures the force per unit area applied parallel to a material’s surface, playing a crucial role in rheological analysis by characterizing material flow behavior and defining the force needed to start moving a material at rest.

What is the role of shear rate in rheological measurements?

Shear rate is pivotal in rheological measurements as it helps study the flow behavior of materials under varying rates of deformation, especially in non-Newtonian fluids where viscosity varies with different rates of deformation.

Related Blogs for Rheometry:

Top Asphalt Testing Solutions for Pavement Performance

Asphalt Testing Equipment: A Comprehensive Guide

Asphalt Testing: Equipment, Solutions, and Engineering

Benefits of Asphalt Binder: A Comprehensive Guide

Rice Testing: Guide to Asphalt Specific Gravity Testing

Understand Viscosity of Asphalt: Dynamic and Kinematic

Asphalt Testing Equipment: A Comprehensive Guide

Five Asphalt Repair Tips for Surfaces to Save Time and Money

Asphalt Testing: From Materials Testing Experts

Viscometer Brookfield Range: Guide To Mastering Consistency

Exploring the Rotational Viscometer for Fluid Flow Analysis

Understanding the Viscosity of Water: A Comprehensive Guide

Kinematic Viscosity of Water: A Comprehensive Guide

Mastering the Viscometer: Guide to Measuring Fluid Viscosity