A turbidimeter is an essential tool for measuring water clarity, a key indicator of water quality. By emitting light through a sample and measuring scattered light intensity, this device gauges the relative turbidity, – or haziness – caused by particles suspended in water. The resulting data is crucial for environmental monitoring, industrial processes, and ensuring safe drinking water. So, what is a turbidimeter? It is an indispensable instrument for assessing water quality and clarity.

Key Takeaways

- What is a turbidimeter? Turbidimeters are instruments that assess water clarity by measuring scattered light due to suspended particles, with factors such as light source type, angle of measurement, and detector influencing the accuracy of turbidity measurements.

- Regular calibration and verification against standards are crucial for maintaining the accuracy of turbidimeter readings, which are vital for various practical applications including environmental monitoring and industrial processes.

- Accurately measuring turbidity requires preparing samples properly and maintaining equipment routinely. Choose the right turbidimeter by considering measurement range, accuracy, standards compliance, and whether a benchtop or portable model suits the application.

Understanding What Is A Turbidimeter

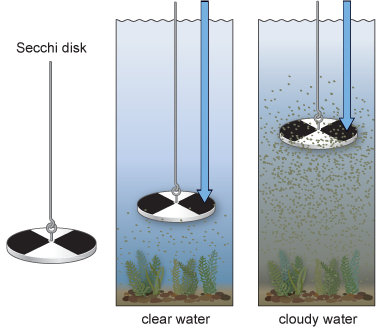

Turbidimeters, which lie at the core of turbidity measurement, are instruments designed to assess the clarity of water or other fluids by detecting scattered light. How does it do this? Here’s a simplified explanation. When a turbidimeter sends light through a water sample, the suspended particles in the sample interact with the light. This interaction results in the light being scattered, and it’s this same light-scattering effect that the turbidimeter measures to indicate the sample’s turbidity. Understanding this will go a long way to answering the question, “What is a turbidimeter?”

The type of light source utilized can vary depending on the specific turbidimeter. These typically include white light or near-infrared at 860 nm. The angle of measurement is a crucial aspect as it affects the resolution and intensity of scattered light, which, in turn, is critical for accurate results. For instance, a 90-degree detection angle is typically used for low turbidity measurements, while a 180-degree angle is preferred for high turbidity measurements. The choice of incident light, or the light beam, can also influence the quality of the scattered light measurement.

In summary, a turbidimeter acts as a guide, shedding light on the turbidity levels of water or other fluids. By measuring optical properties and how much light gets scattered, a turbidimeter offers invaluable insight into the level of particulate matter in a sample, thereby providing a reliable indication of water quality.

Components of a Turbidimeter

Having grasped the basic principle of a turbidimeter, we can now examine its components more closely. Every turbidimeter comprises three main parts: the light source, the sample chamber, and the detector.

The light source in a turbidimeter can vary, with options including tungsten filament lamps, light emitting diode (LED), and lasers. Tungsten filament lamps provide a broad wavelength range of polychromatic light, which is commonly used in turbidimeters. On the other hand, LEDs and lasers serve as monochromatic light sources, which reduces interference light transmitted both from sample color and organic matter, thus offering more consistent readings. In this context, the term “transmitted light” refers to the light that passes through the sample in the turbidimeter.

When it comes to the sample chamber, it’s often a cuvette designed to allow light transmission with minimal interference. These cuvettes are typically made of glass or other clear materials. But it’s not just the material that matters; the condition of the cuvette also plays a significant role. For instance:

- Scratches on the cuvette can impact the accuracy of measurements

- It’s recommended to keep cuvettes free of scratches

- Treat them with substances like silicone oil if minor imperfections are present

Lastly, the detector in a turbidimeter captures the light scattered by particles in the water, with options including photodiodes, photomultiplier tubes, or cadmium sulfide photoconductors.

What is A Turbidimeter: Types

Having covered the basic components of a turbidimeter and discovered what is a turbidimeter, we can now explore the different types of turbidimeters. There are two main types: nephelometers and absorptiometers.

Nephelometers are turbidimeters that detect light scattered by particles in a sample, typically at a 90-degree angle. They are well-suited for analyzing samples with low turbidity levels. Absorptiometers, on the other hand, measure the decrease in light intensity as it passes through a sample. They are better suited for samples with higher turbidity, although their sensitivity can be reduced in very low turbidity conditions and can be influenced by watercolor.

Some advanced turbidimeters integrate features from both nephelometers and absorptiometers to broaden the range of turbidity they can accurately measure. The choice between a nephelometer and an absorptiometer typically depends on the expected turbidity range of the water samples and the specific needs of the water quality assessment task.

Turbidity Measurement Units

Turbidimeters express the results of a turbidity measurement by quantifying the intensity of light scattered by particles in a water sample, which is measured in Nephelometric Turbidity Units (NTUs). To measure turbidity, the NTU is the most commonly used unit in water. However, it’s not the only one. Another defined unit for measuring turbidity is the Jackson Turbidity Unit (JTU). A device that measures turbidity effectively is crucial for accurate results.

While these units might seem a bit complex, they are simply a measure of the amount of light that gets scattered due to suspended particles and suspended or dissolved solids in a water sample. The higher the NTU or JTU value, the greater the turbidity level, indicating a higher concentration of suspended particles in the sample.

Calibration and Accuracy

Regular calibration and verification are fundamental to ensuring the accuracy of NTU or JTU readings from a turbidimeter. Calibration involves adjusting the turbidimeter to match a controlled reference value, while verification involves a quick check against a more standard unit. It’s crucial to follow the specific calibration instructions for a given instrument, which may vary between different models and manufacturers.

Perform recalibration after any significant maintenance, such as changing the light source or cleaning the instrument, to ensure accurate readings. Use turbidity standards like formazin or its stabilized commercial form for calibration. The accuracy of turbidimeter readings should be routinely verified using primary or secondary turbidity standards or by comparison to another calibrated instrument.

Regular calibration and verification not only ensure accuracy but also help meet regulatory requirements. For instance, the EPA recommends quarterly calibration for turbidimeters, and maintaining calibration records is a necessity as per regulatory bodies.

Factors Affecting Turbidity Measurements

Despite turbidimeters being designed for accurate turbidity measurements, several factors in liquid samples can still influence these readings. One of the primary factors is the particle size and color, which can affect the direction and intensity of scattered light, thereby impacting turbidity measurements. The size, shape, and composition of the material in water samples can also influence turbidity readings and this is why we must explore what is a turbidimeter.

The type of light source used in a turbidimeter can also affect the accuracy of turbidity measurements. For instance, monochromatic LEDs or lasers provide more consistent readings compared to tungsten lamps or filament lamps, which have a wider wavelength range that can interfere with the accuracy of turbidity measurements. Moreover, data collected using turbidimeters with infrared light sources are not directly comparable with those using white light sources due to the different behavior of particles under light of varying wavelengths.

Another factor in answering the question “What is a turbidimeter” is the color of the water sample. Some colored particles may absorb light beams, particularly in absorptiometry-based devices, which can skew turbidity measurements. Various factors, including the color of dissolved constituents, particulate materials, and differences in the optical design of nephelometers contribute to the variation in turbidity readings.

Addressing Limitations

Considering these factors that may influence the accuracy of turbidity measurements, it is evident that mitigating these limitations is of paramount importance. Thanks to advancements in technology, state-of-the-art turbidity meters installed in rivers enable instantaneous turbidity readings, which is crucial for overcoming the limitations associated with delayed measurement results.

Moreover, to achieve a more comprehensive analysis of water quality and elements that affect turbidity, advanced turbidity meters can be integrated with additional sensors monitoring conductivity and temperature. Certain methods, such as the ratio method, can also address problems related to backscattered or attenuated light in samples with high turbidity and is in compliance with Standard Method 2130B and the USEPA Interim Enhanced Surface Water Treatment Rule.

Applications of Turbidimeters

Moving forward in answering what is a turbidimeter … Turbidimeters transcend beyond just numbers and units; they serve a critical role in a range of practical applications. They are commonly utilized across industries, research settings, and environmental monitoring to ensure the quality of water and other transparent media. The implications of turbidity are significant, affecting everything from aquatic life to the taste of consumable beverages.

In industrial applications, turbidity meters play a critical role in processes which require the immediate detection of changes in turbidity measured liquid media consistency.

Environmental Monitoring

Environmental monitoring water quality is one of the key areas where turbidimeters prove invaluable. Turbidity measurements are essential in understanding water clarity and the presence of suspended particles that can affect aquatic ecosystems, such as:

- soil particles

- algae

- plankton

- microbes

- other substances

High turbidity can signal the effects of runoff from construction, agricultural practices, and urban development, leading to increased erosion and pollution in waterways, which negatively impacts the ecosystem.

Regular monitoring of turbidity is vital for detecting trends that might indicate environmental degradation, such as:

- increasing erosion in developing watersheds

- high concentrations of particulate matter

- ecological changes like increased sedimentation

- pollution from metals and bacteria attached to particles

- weather events

- fluctuations in water flow

Turbidimeters provide real-time data that can inform conservation efforts and are essential for assessing sediment levels for aquatic ecosystem protection.

Industrial Processes

Beyond environmental monitoring, turbidimeters also play a crucial role in various industrial processes. For instance, in the food and beverage industry, turbidity measurements can indicate the presence of solids, affecting taste and clarity. This is vital as consumers often avoid beverages with unusual color or cloudiness.

Industries such as mining, pulp and paper, aquaculture, and those utilizing cooling systems also rely on turbidity measurements to manage environmental impact, ensure product quality, and maintain efficient operations. Transmittance turbidimeters, for example, are used to assess the cleanliness of filter media by measuring light transmittance, thus ensuring the effectiveness of filter backwash processes.

Choosing the Right Turbidimeter

Given a thorough understanding of turbidimeters and exploring what is a turbidimeter, now we must look at how one selects the appropriate one? A lot depends on the specific application requirements. For instance, if you’re dealing with high turbidity levels for certain industrial applications, you’d need a turbidimeter with a measurement range that accurately captures these levels. Accuracy is a key consideration too, as it ensures that the turbidity measurements are reliable and can be confidently used for quality assessments or regulatory compliance.

Moreover, it’s important to ensure that the turbidimeter is compliant with relevant regulations, such as EPA Method 180.1 or ISO 7027. This not only ensures legal standards adherence but may be a requirement depending on the application.

Benchtop vs. Portable Turbidimeters

The decision between a benchtop or portable model is another consideration when selecting a turbidimeter. Benchtop turbidimeters are known for high precision and are commonly used in laboratory settings with stable conditions. Benchtop meters excel in measuring low-turbidity samples with high accuracy. Their design includes glass sample containers and ratio technology. These meters are ideal for lab-analyzed samples. Transported samples benefit from controlled, precise turbidity measurements.

On the other hand, battery-operated and rugged portable turbidimeters are essential for field measurements in various environments. Their durability enables use in remote locations where laboratory-grade stability isn’t possible. Portable turbidimeters offer versatility outdoors but are pricey and fragile, often requiring controlled settings for accuracy. Other field options may prove more robust and cost-effective. Yet, they lack the portability of turbidimeters.

Compliance and Standards

Adherence to standards is a further crucial factor in the selection process of a turbidimeter. Standards such as ISO 7027, ASTM D7315, and the EPA’s own guidelines are critical for turbidity measurement and compliance with regulatory requirements. Turbidity measurements are integral to EPA drinking water compliance, ensuring water quality and providing early warnings of filter issues.

Different standards require different light sources. For instance, EPA Method 180.1-compliant instruments typically use tungsten lamps, while ISO7027-compliant devices use infrared LEDs. Therefore, considering the compliance standards that a turbidimeter meets is an important part of the selection process.

Tips for Proper Turbidity Measurement

There are several best practices to follow to guarantee the highest accuracy in turbidity measurements. These include proper sample preparation, regular calibration, and routine maintenance.

Sample Preparation

Proper sample preparation begins with ensuring the integrity of the cuvette and the sample vial. These should be free from scratches and imperfections, as these can impact the accuracy of measurements. However, any fingerprints, dust, or spots on the cuvette must be wiped with a lint-free cloth, and handling should be limited to the ends or lid to prevent affecting the light transmittance.

To ensure accurate turbidity measurement, follow these steps:

- Shake the water sample to disperse any particles.

- Allow the sample to rest until air bubbles dissipate.

- Protect the sample from condensation.

- Use clean sample containers.

- Fill the containers correctly without creating bubbles.

- Introduce the sample to the turbidimeter promptly to maintain measurement accuracy.

By following these steps, you can prevent inaccuracies in turbidity measurement and discover what is a turbidimeter.

Calibration and Maintenance

Regular calibration against standards is essential for accurate turbidity measurements. Calibration involves adjusting the turbidimeter to match a controlled reference value, while verification involves a quick check against measured value against a standard. Turbidity meters should be calibrated using the appropriate calibration standard in each measuring range to maintain accuracy.

Turbidimeter maintenance involves:

- Frequent cleaning of the detector to prevent fouling

- Cleaning of the cuvette, which includes removing stains and rinsing with high purity water

- Keeping the glass cells optically clear and free of scratches

Verification should be consistent among all staff, with standard operating procedures recommended, and should be performed periodically to ensure accuracy.

Following these tips and taking care of your turbidimeter can go a long way toward ensuring accurate and reliable turbidity measurements.

Summary

What is a turbidimeter? We explored how turbidity sensors and turbidimeters function and their different types. Factors affecting their readings and solutions were discussed. We examined their applications in environmental monitoring and industrial processes. Finally, we learned how to select and properly use a turbidimeter.

Turbidity is a critical indicator of water quality, and turbidimeters play a pivotal role in assessing it. Additionally, by ensuring the correct use and maintenance of these devices, we can accurately measure turbidity and contribute to the preservation of our precious water resources. So, the next time you look at a body of water, remember that there’s more than meets the eye – and a turbidimeter can help you see it.

Frequently Asked Questions about What is a Turbidimeter

What is a turbidimeter?

A turbidimeter works by emitting light into the water sample and measuring the amount scattered by suspended particles. It then uses a light detector to measure the reflected light, providing a turbidity measurement in NTU or FNU.

What is turbid used for?

Turbidity is used as a measure of the clarity of water and is a useful methodology to determine the quality of water in a sample, especially in assessing drinking water. It is typically clear and colorless with very low or almost zero turbidity values.

Why use a turbidity meter?

Turbidity meters are used to measure water quality, reduce waste, enhance sustainability, and control consumables by detecting when a liquid media reaches a specific specification. Using a turbidity meter can help in maintaining and improving water quality.

What is an example of a turbidimeter?

An example of a turbidimeter is the YSI EXO or YSI ProDSS with a turbidity sensor, which can be used as a benchtop meter, continuous flow meter, or submersible sensor. Spectrophotometers direct a beam of light at a specific wavelength through the sample. This is one of the important in learning about what is a turbidimeter

What is turbidity?

Turbidity is a measure of the clarity of water, with higher turbidity indicating a greater concentration of suspended particles in the water. It is important for water quality assessment and can impact aquatic life.

Related Blogs for What is A Turbidimeter

What Is Turbidimetry: Clarity in Measurement Techniques

Kinematic Viscosity of Water: A Comprehensive Guide

Understanding the Viscosity of Water: A Comprehensive Guide

What is the Boiling Point of Water in Celsius: A Clear Guide

Ensuring Safety: How Often Test Well Water for Contaminants

Test Water Quality: How and Why