Navigating the intricacies of the sieve size chart just got easier. Our article breaks down the confusing terms and measurements into a succinct guide that quickly connects sieve apertures with their relevant mesh sizes and numbers – all aligned with the precise standards of the ASTM and ISO specifications. Discover how to confidently select the correct sieve for your analytical needs, step by step, with clear guidance awaiting in the sections ahead.

Key Takeaways

- A sieve size chart details various sieve opening sizes and is critical for particle size analysis, adhering to the American Standard Test Sieve Series (ASTM) specifications, with industry-specific variations for particular applications.

- Mesh size is a crucial parameter in particle size analysis, affecting separation precision and influencing material properties such as flow behavior and reactivity, with selection contingent on the desired particle retention size.

- Regular sieve maintenance, including cleaning and proper storage, as well as professional sieve verification services, are essential for maintaining performance, and accuracy, and extending the sieve’s lifespan.

Deciphering the Sieve Size Chart

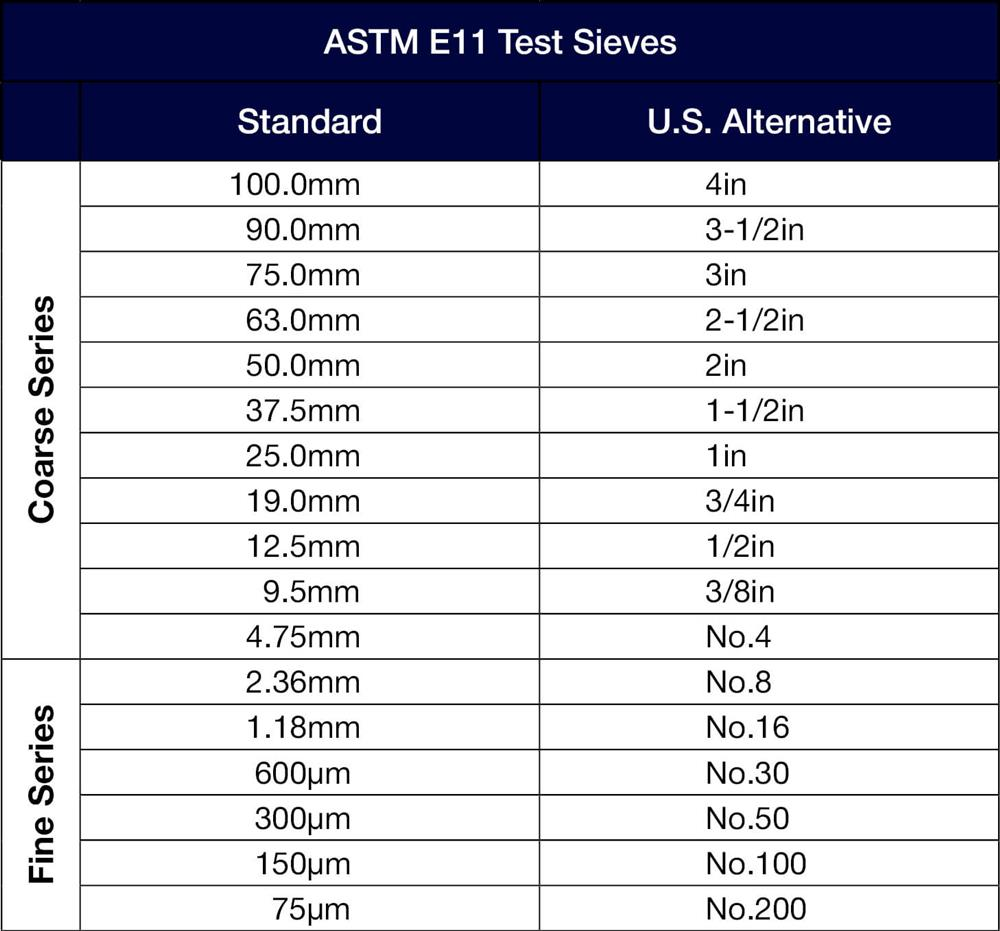

A sieve size chart serves as a key reference tool, providing details about the opening sizes of various sieves used in particle size analysis. This chart, adhering to the American Standard Test Sieve Series (ASTM) specifications, encompasses various aperture sizes, sieve designations, and nominal sieve openings, and may incorporate comparative measurements in inches, millimeters, or microns.

Interpreting the values on a sieve size chart involves a specific process: weighing the sieve pans post-sample processing, analyzing the masses retained, and then organizing the sieve data.

Notably, these charts can vary across different industries due to specific applications and requirements that may necessitate the use of certain sieve sizes or sets of sieve sizes.

The Significance of Mesh Size in Particle Size Analysis in a Sieve Size Chart

Mesh size, which signifies the dimension of the sieve openings, holds significant sway over the determination of particle size distribution. Choosing the correct mesh size is critical for efficient sieving operations as a too-large mesh aperture size can lower the efficiency by allowing larger particles to pass through, leading to skewed results. The use of different mesh sizes can substantially impact the outcomes of particle size analysis, altering the particle size distribution, and consequently influencing material properties such as flow behavior, reactivity, and solubility.

Hence, the selection of mesh size should take into account both the particle retention of fine mesh size and the size of particles that need to be separated.

Mesh Size and Particle Passage in Sieve Size Chart

The correlation between mesh size and particle passage in a sieve is a straightforward one. Smaller mesh sizes feature smaller openings, allowing smaller particles to pass through, whereas larger mesh sizes have larger openings, enabling particles larger than particles to pass through. Thus, mesh size may affect the precision of particle separation.

The segregation of material passing through a series of sieves with varying mesh sizes helps to determine the character and distribution of particle sizes within the sample. This is a crucial aspect of maintaining quality and consistency in industrial applications.

Typical Wire Diameter and Its Impact in Sieve Size Chart

The diameter of the wire used in a sieve can have a profound impact on its performance. A thicker wire diameter can lead to smaller openings, which can cause particle plugging and affect the sieving process. Conversely, a larger wire diameter leads to increased structural openings, reducing the likelihood of particles being smaller and of clogging and consequently maintaining the integrity of the sieve analysis results.

Furthermore, the wire diameter has a significant effect on both the longevity and robustness of a sieve. Thicker wire diameters offer increased strength, enhancing the durability of the sieve and leading to a longer lifespan.

A Closer Look at Test Sieves and Their Standards in Sieve Size Chart

Test sieves are invaluable tools in the world of particle size analysis. Typically manufactured from stainless steel or brass for durability and corrosion resistance, these sieves adhere to strict ASTM E11 standard specifications to guarantee precision and quality. Besides ASTM standards, ISO also outlines specifications for sieves with a unique methodology, for testing materials, particularly in areas such as nominal aperture size ranges.

ASTM E11 Standard Explained

The ASTM E11 standard holds a pivotal role in particle size analysis as it regulates the manufacturing of test sieves, ensuring adherence to specific tolerances for mesh openings, wire diameters, frame sizes, and cloth mounting requirements. Specifically, the ASTM E11 standard delineates criteria measurement tolerances for standard, alternative, and supplementary sizes of woven wire sieve cloth, sieve construction, frame sizes, and inspection of sieves and sieve cloth for sieves ranging from 125mm to 20µm.

Since its complete revision with the -09 amendment, the ASTM E11 standard has seen further revisions to align with the specifications for the design and construction of testing sieves using woven wire cloth.

ISO Sieve Specifications

ISO sieve specifications, as outlined in the standard ISO 3310-1:2016, encompass the technical requirements and test methods for metal wire cloth test sieves. These specifications play a crucial role in ensuring precise particle size analysis by establishing standard sieve sizes. Like their ASTM counterparts, ISO test sieves are commonly manufactured with stainless steel frames and mesh, or brass frames with stainless steel mesh.

Guide to Selecting the Right Sieve for Your Needs

Choosing the right sieve for your specific needs is indeed a significant decision. The selection can be influenced by various factors, including the specific requirements for particle size analysis, particle shape assessment, and product quality control in different industries. Whether it’s the pharmaceutical industry that requires sieves to ensure product quality and integrity, or the food industry employing drum sieves, disc sieves, and vibrating screens for processing inert materials, the choice of sieve size is directly linked to the particles’ ability to pass through the sieve mesh effectively.

Factors Influencing Sieve Choice

A multitude of factors influence the choice of a sieve. Some key determinants affecting the selection of a sieve include:

- The size of particles to be separated

- The size of the openings in the sieve

- The material to be sieved

- The particle retention size, which is measured in microns

- The specific size of the particles requires separation to guarantee precise and significant analysis outcomes.

Industry-Specific Sieve Selection Examples

Selecting the right sieve is a tailored process, highly dependent on the specific industry and its requirements. Here are some examples of sieve selection in different industries:

- Pharmaceutical industry: often relies on Glenammer woven wire sieves for their applications.

- Food industry: commonly employs sieve sizes that encompass 100, 200, 325, and 400 mesh.

- Mining sector: sieves are chosen based on their ability to classify particles encountered in mining.

- Construction materials industry: specific sieve selection examples include the sieving of soil samples and aggregates.

Sieve Size Chart Equipment Essentials: Sieving Tools and Accessories

In particle size analysis, possessing the appropriate, sieving equipment, tools and accessories can be a game changer. Whether it’s wet sieving tools, brushes, scoops, or sieve cleaners, these vital tools aid in the sieving process, contributing to accurate and efficient results.

Among these tools, sieve shakers are instrumental. They facilitate the movement of particles through a series of sieves, effectively sorting them based on size. Equally important are sieve pans and covers, which are strategically placed to gather materials and prevent sample loss and contamination throughout the sieving process.

The Role of Sieve Shakers

Sieve shakers, such as the sieve shaker, are integral to the sieving process. By facilitating the movement of particles through the sieve, they enable effective sorting based on size. Their ability to automate the agitation of particles leads to greater accuracy and faster processing times.

These shakers come in various varieties, such as mechanical sieve shakers, vibratory sieve shakers, and sonic sieve shakers, each catering to specific applications and needs.

Importance of Sieve Pans and Covers

Though they may appear as simple accessories, sieve pans and covers hold a fundamental role in the sieving process. Placed at the base of the sieve stack, pans gather the materials that have passed through the two sieves together. Covers, on the other hand, are used at the top to safeguard against material loss and contamination throughout the sieving process. These accessories are vital in preventing sample loss and contamination during manual or mechanical agitation and also safeguard against alterations in moisture conditions.

Like all brass sieves, sieve pans, and covers, brass sieve cloth is commonly constructed from stainless steel or brass.

Maintaining and Verifying Your Sieves for Optimal Performance

Regular maintenance and verification of your sieves is key to ensuring their longevity and performance. This includes cleaning them properly after each use, storing them in a dry and clean environment, and conducting periodic sieve verification to assess the mesh openings.

Cleaning and Storage Recommendations

Proper maintenance of sieves can significantly enhance their lifespan and performance. When cleaning sieves, follow these steps:

- Turn the sieve over a receiving pan.

- Gently brush the underside of the mesh to dislodge particles.

- For metal test sieves, use a soft bristle brush with care.

- Use a mild cleaning solution such as dish detergent or Simple Green to assist in removing stubborn remnants.

By following a few examples of these steps, you can keep your sieves clean and in good working condition.

After cleaning, sieves should be stored in a clean, controlled, and dry environment to ensure accuracy is maintained.

Professional Sieve Verification Services

Sieve verification is an essential part of maintaining the performance and accuracy of your sieves. This process includes:

- Upgraded test sieve calibration

- Inspection

- Master-matched certification

- Providing a mesh-certified sieve with a certificate

These services ensure that a sieve complies with or surpasses standards, guaranteeing optimal performance.

Entities such as Global Gilson and W.S. Tyler are recognized for providing these services, which adhere to stringent standards like ASTM E11 to ensure accurate and repeatable test sieve analysis results.

Practical Tips for Effective Sieve Analysis

Several practical tips can help in ensuring accurate and efficient sieve analysis. These include proper sample preparation, the right sieving procedure, and understanding common sieving terminology. Whether it’s the collection, homogenization, and reduction of samples or the step-by-step guide to the sieving process, understanding these tips can significantly enhance the efficiency and accuracy of your sieve analysis process.

Sample Preparation Best Practices

Accurate sieve analysis relies heavily on proper sample preparation, as it is crucial for obtaining reliable results. Without it, the integrity of the analysis may be compromised. This involves:

- Evenly pouring the sample around the surface of the top sieve

- Employing dry sieving for the suitable size range

- Acquiring a representative oven-dried soil sample

- Finely pulverizing the soil sample

- Utilizing ultrasonic cleaning to eliminate particles trapped in the mesh

- Weighing the sample before placing it on the top sieve

It’s also crucial to consider the sample composition, which includes factors such as particle form, size, and agglomeration, as these can significantly impact the results of sieve analysis.

Step-by-Step Sieving Procedure

Following specific steps during the sieving procedure ensures accurate results. The material should be shaken for an initial test time of typically 3-5 minutes, although for small shakers grading fine aggregate samples, shaking times of 15 minutes may be necessary.

Following the shaking process, the material retained on each sieve is meticulously weighed, and the mass of the sample on each sieve is divided by the total mass to determine the percentage of mass retained on each sieve.

Understanding Sieving Terminology

Understanding the terminology simplifies the task of navigating through the world of sieving. Terms like:

- sieve

- mesh

- particle size

- sieve analysis

- agglomerated material

are commonly used in this field. For instance, mesh size is a measure of particle size commonly used in the assessment of the particle-size distribution of a granular material. Similarly, sieve efficiency refers to the efficacy of the sieving process in segregating particles into specific sizes.

Navigating Different Sieve Designations and Their Uses

Understanding the various sieve designations used across different industries is key to accurate particle sizing. Different industries often specify specific sieve sizes or a series of sieve sizes to categorize specific types of materials. For instance, U.S. Standard Mesh sieves are used extensively in industries such as:

- food

- pharmaceutical

- agriculture

- mining

For particle size distribution analysis.

On the other hand, metric sieve sizes are used to characterize particle size in representative samples and assess the size distribution of particles in a sample.

U.S. Standard Mesh vs. Metric Sizes

When it comes to sieve sizes, U.S. Standard Mesh sizes and Metric sizes each have their own unique applications. U.S. Mesh sizes range from 3 1/2 to 400, indicating the number of openings per linear inch. These sizes are considered standard for various applications.

Meanwhile, metric sieve sizes, expressed in millimeters, are used for various applications, such as the sieving of soil samples in the agricultural industry or the analysis of pharmaceutical powders in the pharmaceutical industry.

Specialized Sieves for Unique Applications

Beyond standard sieves, there are specialized sieves designed for unique applications and industries. These sieves, such as non-metallic sieves constructed from polyester or nylon filament, air jet sieving, and metal or synthetic woven wire mesh sieves, have applications in research and development, environmental monitoring, and various industries including analyzing pharmaceuticals, powders, and granular materials. These specialized sieves often exhibit decreased tolerances and incorporate reinforced frames or anti-blinding coatings to cater to specific applications.

Summary

In conclusion, understanding sieve size charts, mesh sizes, and sieve designations is crucial for accurate particle size analysis. By maintaining and verifying your sieves, choosing the right sieve for your needs, and understanding common sieving terminology, you can enhance the efficiency and accuracy of your sieve analysis process. Whether you’re working in the pharmaceutical, food, mining, or any other industry requiring particle size analysis, mastering these aspects of sieving can help you ensure quality and consistency in your industrial applications.

Certified MTP has the largest selection of aggregate testing supplies, showcasing industry-leading brands for Sieve Shaker Machines, test sieves, Classification Devices for Aggregate Testing, Sample Splitters and Dividers, and Specific Gravity Test Equipment.

Frequently Asked Questions

What are the standard sieve sizes on a sieve size chart?

The standard sieve sizes in the U.S. range from 3 inches to 12 inches, with opening sizes from 5 inches (125 mm) to 635 mesh (20 microns). These sizes cater to a wide range of particle sieving needs.

How big is a #4 sieve?

A #4 sieve has a nominal sieve opening of 4.75mm.

What is the difference between sieve size and mesh size?

The main difference between sieve size and mesh size lies in their definitions. Sieve size refers to the number of openings in one square inch of a screen, while mesh size refers to the mesh number and to the size of the openings in the screen (e.g., a 36 mesh screen will have 36 openings while a 150 mesh screen will have 150 openings).

What size is a number 10 sieve?

A number 10 sieve has a 0.0787″ (2mm) nominal sieve opening with a typical wire diameter of 0.9mm, making it a medium size sieve designated the U.S. Standard mesh size.

What is a sieve size chart and why is it significant in particle size analysis?

A sieve size chart is important in particle size analysis as it provides details about sieve opening sizes, aiding in classifying particles and determining particle size distribution for various test applications in both U.S. and metric systems.

View the full line of Aggregate Testing Products and Aggregate Moisture Testing Equipment, especially the popular Aggregate/Sand Moisture Measurement System

Related Blogs for Sieve Size Chart

Sieve Brushes for Efficient Cleaning and Maintenance

Top Scrub Brush for Concrete: Your Ultimate Cleaning Tool

Quality Lab Brushes for Efficient Cleaning and Maintenance

Retsch AS200 Sieve Shaker: Mastering Particle Size Analysis

ASTM C136: Guide to Fine and Coarse Aggregate Sieve Analysis

Sand Sieve Size: A Guide for Optimal Sifting

Sieves for Soil: Finding the Perfect Match for Gardening

Sieve Analysis of Soil: A Guide to Particle Size Assessment

Understanding Aggregate Sieve Sizes: A Comprehensive Guide

ASTM Sieve Sizes: A Complete Sizing Chart Breakdown

Graph for Sieve Analysis: A Guide to Accurate Soil Grading

Sieve Test: A Guide to Particle Size Analysis

Top-Quality Sieves for Precise Material Separation

Sieve Mesh Sizes: Guide to Understanding Different Mesh

Sieve Essentials: Understanding Its Functions & Applications

The Ultimate Sieve for Compost Mastery: Simplify Your Soil

Sieve Shaker for Sale: Find the Perfect Fit for Your Lab

Sifting with Gilson Sieves: Your Guide to Material Analysis

Gilson Sieve Shaker: Particle Size Analysis

Sieve Shaker Selection: Find the Model for Material Analysis

Top Standard Test Sieves for Accurate Material Analysis

Using Retsch Lab Sieves and Sieve Shakers for Analysis

What is a Shaker Sieve and Particle Sizing Analysis

Understanding ASTM D 422: Sieve Analysis and Particle Size

Sizes of Sieves: A Comprehensive Guide

Sieve Analysis: A Guide to Grain Size Distribution

Understanding Sieves: A Comprehensive Guide to Test Sieves

Selecting Sieve Sizes: Tips for Soil, Sand & Aggregate

Complete Guide to US Sieve Sizes

Gilson Company Testing Equipment: Discover Durability

Gilson Screens: Discover the Benefits

Exploring What is Sieving Used For: Applications & Technique