Have you ever wondered how grain quality and quantity are determined in the agricultural world? Accurate grain scale test weight measurements play a crucial role in assessing grain value, optimizing transportation, and ensuring proper storage and processing. In this blog post, we will delve into the importance of grain scales, factors affecting test weight measurements, calibration methods, and the practical applications of grain scale test weights.

Key Takeaways

- Understanding grain scales and their importance is essential for accurate test weight measurements.

- Factors such as moisture content, environmental conditions, and handling/storage practices can significantly impact results.

- Grain scale calibration helps ensure precise test weight measurements to optimize grain management decisions.

Understanding Grain Scales and Their Importance

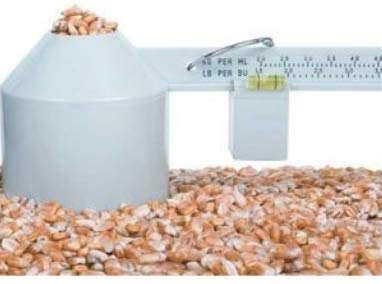

Grain scales serve as vital instruments for gauging test weights, which in turn helps establish grain quality and worth. Test weight is a ratio between weight and volume, calculated as the weight of grain that fills a quart container. Higher test weight grain is generally considered to be of better quality than drier grain, as it can be an indicator of factors such as genetic yield potential and disease resistance.

Comprehending the functionality of grain scales and the variety of types available is key for precise measurements.

How Grain Scales Work

Grain scales function by weighing a specific volume of grain and calculating the test weight based on the mass-to-volume ratio. They rely on load cells, devices that measure weight or force, to which strain gauges are attached. These gauges measure the deformation of the load cell when a force is applied.

The electrical signal from the strain gauges is converted into a weight reading by a circuit connected to the load cell, and the weight is displayed on a digital scale.

Types of Grain Scales

A variety of grain scales are available, including:

- Micro weighing systems

- Minor and bulk weighing systems

- Bulk bag unloading and weighing systems

- Reloading scales

- Economy test weight scales

- Truck scales

- Bench scales

Micro weighing systems are designed for small quantities of grain, for example while minor and bulk weighing systems handle larger quantities.

- Micro weighing systems: designed for small quantities of grain

- Minor and bulk weighing systems: handle larger quantities

- Bulk bag unloading and weighing systems: used for unloading and weighing large quantities of grain

- Reloading scales: help weigh grain being transferred between containers.

Each type of grain scale has its advantages and disadvantages, depending on the specific application.

Factors Affecting Test Weight Measurements

Factors like grain moisture content, environmental conditions, and handling/storage practices can sway test weight measurements. These factors can lead to reduced test weight increases or weights, which may affect the overall value and quality of the grain.

Recognizing these factors is crucial for guaranteeing precise test weight measurements and enhancing grain quality.

Grain Moisture Content

High grain moisture content can lead to low test weight grain, as moisture and test weight are inversely related. As grain dries, its density and test weight typically increases.

The formula for calculating the test weight increase with grain drying is:

- (A / B) x C

- A is equal to 100 minus the dry moisture content

- B is equal to 100 minus the wet moisture content

- C is the test weight at the wet moisture content

Grain moisture content must be considered when determining test weight measurements due to its significant impact lower test weight and on the results.

Environmental Conditions

Environmental factors that can impact test weight measurements in corn include:

- Wetting and drying cycles

- Temperature

- Stress during grain fill

- Drought stress

- Late-season foliar leaf diseases (such as northern corn leaf blight)

- Below normal temperatures

- Frost/freeze damage

In the process of understanding corn test weight, it is crucial to consider various factors that can have an effect on corn test weight measurements.

Moreover, the following factors may have an impact on test weight measurements:

- Plant stresses caused by diseases, insects, and environmental conditions such as drought, hail, and stress

- Grain wetting between maturity and harvest

- Grain moisture levels

- Hybrid selection

- Planting date

Overseeing and controlling these environmental factors can aid in achieving precise test weight measurements and preserving grain quality.

Handling and Storage Practices

Appropriate handling and storage practices are crucial to preserving precise test weight measurements and avoiding grain spoilage. Grain should be stored in an environment that is cool, dry, and well-ventilated, and that minimizes the risk of contamination.

To prevent grain spoilage during the grain filling period, it is recommended to regularly inspect the corn grain for signs of mold, insects, and discoloration. If any of these signs are detected, the yellow corn grain should be disposed of.

Ensuring proper handling and storage practices not only maintains accurate test weight measurements but also preserves the overall quality of the grain.

Improving Test Weight Accuracy with Grain Scale Calibration

Frequent calibration of grain scales is fundamental for guaranteeing precise test weight measurements and enhancing the overall grain quality assessment. Calibration involves verifying the accuracy and precision of a grain scale, typically through the use of calibration weights or test weights.

By maintaining accurate test weight measurements, farmers can optimize their grain management decisions and achieve better results.

Calibration Methods

Grain scale calibration employs methods such as standard calibration and custom calibration. The accepted calibration method involves utilizing certified test weights to compare the accuracy of the grain scale.

The custom calibration method entails comparing the measurements of the grain scale with a known standard. Both methods aim to ensure that the scale is accurately measuring the weight of the grains, ultimately contributing to improved grain quality assessment.

Calibration Frequency

The scale’s usage and the manufacturer’s recommendations dictate the calibration frequency, however, it should ideally be conducted at least once a year. Environmental conditions, grain moisture content, and handling and storage practices can affect the scale’s accuracy, and should be taken into account when determining the calibration frequency.

Calibration should be conducted more often if the scale is utilized in a high-traffic setting or if it is exposed to extreme temperatures or humidity. Regular calibration ensures precision and contributes to better grain quality management.

Grain Quality and Test Weight Relationship

Test weight serves as a significant determinant of grain quality, influenced by many factors, like genetic yield potential and the impact of diseases/pests. High test weight grain with higher test weight indicates a better quality product. It is more visually appealing as well.

However, it is important to be aware of grain test weight deception, as other factors such as grain moisture content, environmental conditions, and handling and storage practices can also affect test weight measurements.

Genetic Yield Potential

Genetic yield potential refers to the inherent capacity of a grain variety to produce high test weight measurements and achieve optimal grain yield. This potential can be influenced by breeding and selection, as varieties with higher genetic yield potential can be identified and selected, resulting in higher test weight measurements.

Concentrating on genetic yield potential enables farmers to refine their crop choices, thereby maximizing the quality of their harvest.

Disease and Pest Impact

Diseases and pests can adversely affect grain quality and test weight measurements by directly damaging the grain or diminishing the overall yield. They can cause physical damage to the grain, including discoloration, shriveling, and cracking of small grains.

In addition, diseases and pests can have a detrimental effect on yield by reducing the number of viable grains produced. Implementing preventive measures and controlling diseases and pests can help maintain accurate test weight measurements and ensure high-quality grain.

Practical Applications of Grain Scale Test Weights

Practical applications of grain scale test weights extend to transportation and hauling, marketing and pricing, along with storage and processing of grains. Accurate test weight measurements are essential for optimizing these processes, as they provide essential information about grain quality and value.

A thorough understanding and utilization of grain-scale test weights aid farmers in making superior management decisions, thereby enhancing their operations.

Transportation and Hauling

Accurate test weight measurements help farmers optimize transportation and hauling by ensuring they do not exceed truck weight limits while maximizing payload. Grain trucks of prescribed weight may be subject to fines that exceed the value of the grain transported.

Farmers can evade expensive fines and guarantee efficient grain transportation by verifying truck load weights before dispatching loaded vehicles onto the highway.

Marketing and Pricing

Test weight measurements play a role in determining grain prices, as higher test weights often correlate with better quality and higher market value. Grain scale test weights are employed in marketing and pricing to ascertain the value of the grain being sold, with the test weight of the grain used to calculate the price per hundred bushels, or ton.

Precise test weight measurements can assist farmers in maximizing profits and making well-informed marketing decisions.

Storage and Processing

Proper test weight measurements are essential for efficient storage and processing, as low test weight grains can cause issues with spoilage and processing quality. Accurate test weight measurements ensure that the grain is stored and processed appropriately, taking into account factors such as moisture content and other factors that can affect the quality of the grain.

Maintaining precise test weight measurements enables farmers to refine their storage and processing practices, ultimately leading to superior grain quality and worth.

Summary

In conclusion, understanding grain scales and test weight measurements is crucial for optimizing transportation, storage, and processing, as well as making informed marketing decisions. By taking factors such as grain moisture content, environmental conditions, and handling/storage practices into account, and regularly calibrating grain scales, farmers can ensure accurate test weight measurements and enhance the overall quality and value of their grains. By embracing the knowledge and practical applications of grain scale test weights, farmers can make better management decisions and elevate their agricultural operations.

Frequently Asked Questions

What is grains on a scale?

Grains is a unit of weight equal to 0.065 grams or 1/7,000 pounds of avoirdupois. It is the smallest unit of measure in the avoirdupois, apothecaries, and troy systems and is based upon the mass of a single ideal seed of a cereal. Many industries use it, including jewelry, pharmaceuticals, and agriculture. People also use grains to measure the weight of precious metals, such as gold and silver. Additionally, people use grains to measure their weight.

What is the abbreviation for grains on a digital scale?

The abbreviation for grains on a digital scale is ‘gr.’

What does CT mean on scale?

CT on scale is the unit of mass equal to 200 mg, adopted in 1907 at the General Conference on Weights and Measures and is used for measuring gemstones and pearls.

How do you measure grain test weight?

Test weight is typically measured by weighing a one-quart sample of the grain on a scale, then multiplying the weight by 32 to get the total bushel weight. Stress and frost can cause lower test bushel weights.

How do environmental factors affect test weight measurements?

Environmental factors such as wetting and drying cycles, temperature, and stress during grain fill can significantly affect test weight measurements, making them unreliable.

View the full line of Soil Testing Products, especially the popular Aggregate/Sand Moisture Measurement System

Related Blogs for Grain Scale Test:

Top Moisture Testers: Perfect Match for Your Farming Needs

What Is Test Weight in Grain: Understanding Grain Quality

The Best Moisture Tester for Grain

Finding the Right Moisture Tester for Grain

Best Grain Moisture Tester for Accurate Analysis

Moisture Tester: Get Accurate Results

Dickey John Moisture Tester: Precise Grain Moisture Testing

Dickey John Agricultural Tools: Maximize Your Farm